ChevyParts

My Garage

My Account

Cart

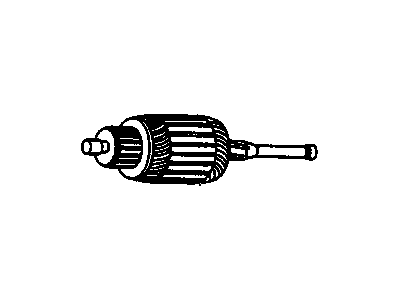

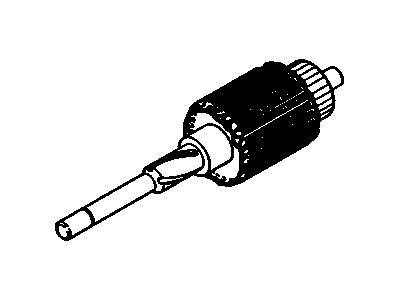

OEM Pontiac Armature

Car Armature- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

13 Armatures found

Pontiac Brushes Part Number: 1971568

$48.51 MSRP: $90.55You Save: $42.04 (47%)Product Specifications- Other Name: Starter Motor Armature; Armature

Pontiac Armature Part Number: 10499097

$93.99 MSRP: $170.11You Save: $76.12 (45%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Armature, Starter Motor

Pontiac Armature Part Number: 10471537

Product Specifications- Other Name: Armature, Starter Motor

Pontiac Armature Part Number: 10521224

Product Specifications- Other Name: Armature, Starter Motor

Pontiac Armature Part Number: 10498530

Product Specifications- Other Name: Armature, Starter Motor

Pontiac Armature Part Number: 10497046

Product Specifications- Other Name: Starter Motor Armature

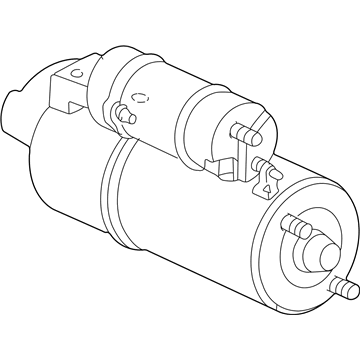

Pontiac Starter Part Number: 10455049

Product Specifications- Other Name: Acdelco Starter; Armature

Pontiac Armature Part Number: 88972441

Product Specifications- Other Name: Armature, Starter Motor

Pontiac Armature Part Number: 10499601

Product Specifications- Other Name: Armature, Starter Motor

Pontiac Armature Part Number: 10490501

Product Specifications- Other Name: Armature, Starter Motor

Pontiac Armature Part Number: 10467708

Product Specifications- Other Name: Armature, Starter Motor

Pontiac Armature Part Number: 10456406

Product Specifications- Other Name: Armature, Starter Motor

Pontiac Armature Part Number: 10456405

Product Specifications- Other Name: Starter Motor Armature; Armature, Starter Motor

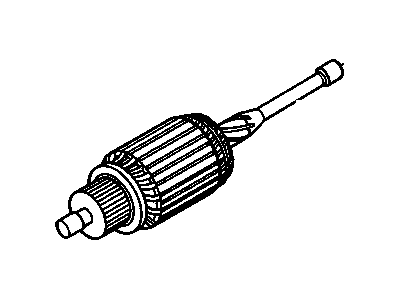

Pontiac Armature

Choose OEM Armature, you're making the optimal decision for superior quality and perfect performance. You can feel confident because each component goes through stringent quality checks. Every part is carefully built to comply with Pontiac's factory specifications. You'll enjoy a smooth, worry-free installation that fits just right. At ChevyPartsGiant.com, you'll find it easy to get top-quality OEM Pontiac Armature. You can shop at highly competitive prices and protect your budget. All our genuine Pontiac parts include a dependable manufacturer's warranty. You'll also appreciate our straightforward return policy and swift delivery services for extra convenience.

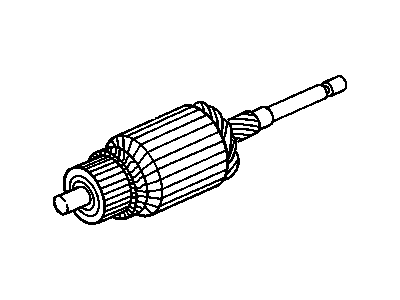

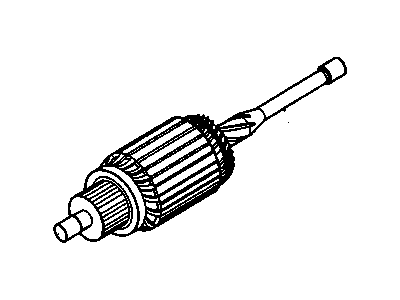

Pontiac Armature transforms the electrical energy that is stored into the rotational power that jerks the engine to life within seconds and all Pontiacs feel you are about to start the moment you turn the key. The Pontiac has created a reputation of wide track stability, bold styling and driver focused cabins combining comfort with athletic ethos since 1926. The wide position holds the car in place during corners and the lines enhanced declare the performance even when it is not moving. These models such as the Firebird and the Grand Am reveal how Pontiac incorporates fun with control whereby the engines are lively but it is coupled with technology that keeps the driver in touch with the road. Even outer changes during decades are based on the same philosophy giving an appearance that remains aggressive without affecting daily usability. The rotating coils within the starter motor are called the Pontiac Armature; the windings are made of copper and as they rotate across a field of magnets they transform electrical energy into smooth mechanical movement. The Armature should be installed by first removing the battery, starter assembly and then scrubbing any debris out of the housing. Check bushings and bearings and then insert the Armature into the field frame making the shaft straight. Position bearings, lightly roll the commutator off the brushes and place thrust washers and end caps. Make all the fasteners fit, rotate the shaft by hand to ensure it is free, re-attach electrical leads, and replace the starter on the engine, and finish with a final test to ensure that it engages crispily each time.