ChevyParts

My Garage

My Account

Cart

OEM Buick Terraza Fuel Rail

Engine Fuel Rail- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

2 Fuel Rails found

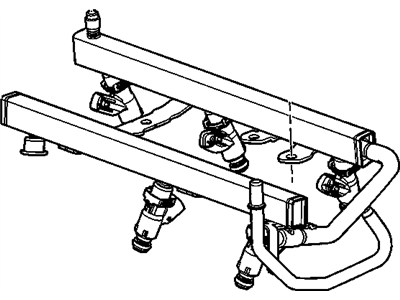

Buick Terraza Fuel Rail Part Number: 12584908

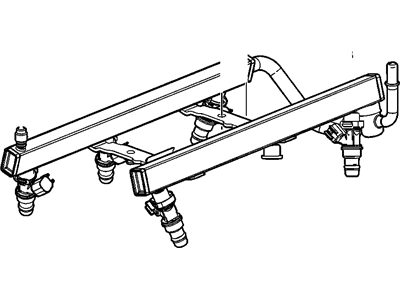

$226.88 MSRP: $460.82You Save: $233.94 (51%)Ships in 1-2 Business DaysBuick Terraza Fuel Rail Part Number: 12587074

Buick Terraza Fuel Rail

Want to cut long-term maintenance and repair costs? Choose OEM Fuel Rail. Those parts deliver top durability you can trust. On our site, you'll find a huge catalog of genuine Buick Terraza parts. Prices are unbeatable, so you can keep more in your pocket. Every OEM Buick Terraza Fuel Rail includes a manufacturer's warranty. You can also get an easy return policy that keeps buying risk free. Fast delivery, get your car on the road quickly. It's simple to search, compare, and order. Stop guessing about quality or fit. Order today and save with parts that last.

Buick Terraza Fuel Rail Parts and Q&A

- Q: How to service and repair the fuel rail and replace the fuel injectors on Buick Terraza?A:The first step to service and fix the Fuel Rail with new Fuel Injectors is to mark down the 8-digit identification code stamped on the rail which will aid in part replacement decisions. Proper placement of the Fuel Injector o-rings reduces the chances of fuel leaks and related fire hazards as well as personal injuries; follow the color coding standard to position the black o-ring above the brown o-ring. Set the fittings with caps to block contaminants when performing servicing actions. Engine oil contamination by fuel occurs when filter leakages are present in the fuel injectors. First disconnect the fuel feed pipe from the Fuel Rail combined with all electrical connectors before you remove the upper Intake Manifold. The procedures involve eradicating the Fuel Injector harness connector bracket bolt on the Intake Manifold followed by disconnecting the camshaft position (CMP) sensor electrical connector. Installation of the Fuel Rail necessitates unfastening all Fuel Rail bolts on the way to extricate the Fuel Rail from its current position. Carefully remove o-rings from the spray tip while keeping electrical pins and nozzles intact and prevent immersion of any cleaner in the Fuel Injector. After getting rid of the Fuel Injector retaining clip and replacing the Fuel Injector there is a need to remove the upper o-ring. New o-ring seals should replace old ones when installing components. Also use the correct injector part number for replacement parts. Clean oil should lubricate all new injector o-rings before installing the upper o-ring followed by Fuel Injector attachment to the Fuel Rail with the Fuel Injector retaining clip. When working on fuel system elements users must cover the Fuel Rail inlet and outlet ports to avoid contamination and must never apply compressed air or solvent baths to touch the Fuel Rail assembly. Install the Fuel Rail assembly into the Intake Manifold by slightly tilting it during installation of the injectors. Use lubricated clean engine oil for the new lower injector o-rings before assembly. After tightening the Fuel Rail bolts to 10 n.m (89 lb in) install the cmp sensor electrical connector, position the bracket that holds the Fuel Injector harness connector to the Intake Manifold while securing the bracket bolt at 8 n.m (71 lb in). To complete the process install the upper Intake Manifold and reconnect electrical connectors and connect the fuel feed pipe to the Fuel Rail. You can identify fuel leakage by first enabling the ignition for 2 seconds followed by turning it off for 10 seconds and enabling it a second time to look for any signs of leakage.