ChevyParts

My Garage

My Account

Cart

OEM Saturn Engine Mount Torque Strut

Engine Torque Strut Mount- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

7 Engine Mount Torque Struts found

Saturn Strut Mount Part Number: 15942412

$21.17 MSRP: $30.57You Save: $9.40 (31%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Strut, Engine Mount Dampening; Engine Mount Torque Strut; Engine Mount Bracket; Motor Mount; Strut

Saturn Strut Mount Part Number: 25840458

$47.98 MSRP: $81.69You Save: $33.71 (42%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Strut, Engine Mount Dampening; Engine Mount Torque Strut; Engine Mount Bracket; Motor Mount; Strut Bracket; Strut

Saturn Strut Part Number: 10247084

$37.86 MSRP: $91.28You Save: $53.42 (59%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Strut, Engine Mount Dampening; Engine Mount Torque Strut; Engine Mount Bracket; Engine Torque Strut; Motor Mount

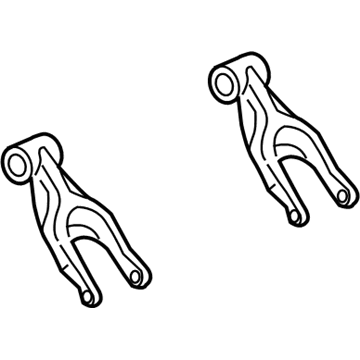

Saturn Strut Bracket Part Number: 21013105

$63.54 MSRP: $99.53You Save: $35.99 (37%)Product Specifications- Other Name: Strut, Engine Mounting; Engine Mount Torque Strut; Motor Mount; Torque Strut Bracket; Strut; Strut, Transmission Mounting

Saturn Strut Assembly Part Number: 21013119

Product Specifications- Other Name: Strut, Transmission Mounting; Engine Mount Torque Strut; Engine Mount Bracket; Motor Mount; Strut Bracket; Torque Strut

Saturn Strut Assembly Part Number: 21013118

Product Specifications- Other Name: Strut, Transmission Mounting; Engine Mount Torque Strut; Engine Mount Bracket; Motor Mount; Strut Bracket; Torque Strut

Saturn Strut Assembly Part Number: 21013013

Product Specifications- Other Name: Strut, Engine Mounting; Engine Mount Torque Strut; Engine Mount Bracket; Motor Mount; Strut Bracket; Mount

Saturn Engine Mount Torque Strut

Choose OEM Engine Mount Torque Strut, you're making the optimal decision for superior quality and perfect performance. You can feel confident because each component goes through stringent quality checks. Every part is carefully built to comply with Saturn's factory specifications. You'll enjoy a smooth, worry-free installation that fits just right. At ChevyPartsGiant.com, you'll find it easy to get top-quality OEM Saturn Engine Mount Torque Strut. You can shop at highly competitive prices and protect your budget. All our genuine Saturn parts include a dependable manufacturer's warranty. You'll also appreciate our straightforward return policy and swift delivery services for extra convenience.

The Saturn Engine Mount Torque Strut minimizes engine roll and vibration resulting in smooth rides and increased lifetime of the drivetrain. Saturn was an ambitious project of General Motors started in 1985, which opened a special facility in 1991, and gained popularity due to dent resistant plastic body panels that moved the parking lot's parking cart hits. The cars made lightweight engines that were crafted using lost foam casting technique, strong multilayer paint, and an ingenious marketing strategy that encouraged consumers to join the team made the cars feel contemporary and welcoming. The large cabins, economical fuel consumption, and perception that Saturn was taking customer ideas also appealed to the drivers and created a strong community that valued long life and minimal running expenses. The Saturn Engine Mount Torque Strut itself is a small dogbone component that would have rubber bushings that hold the powertrain to the subframe and is stout that prevents twisting during the process of absorbing the drive train shock. Installation of a new Engine Mount Torque Strut will require that the brake be set, the engine be supported using a jack and wood block on flat land. Any plastic shields covering the old strut should be removed, the orientation of the latter noted, and the bolts pulled and the strut lifted off. Install the fresh Engine Mount Torque Strut, manually start all the bolts and then lower the jack to fit the bushings and tighten. Refit the parts taken out, start motor and drove some little to make sure there was continuous acceleration and noiseless shifts.