ChevyParts

My Garage

My Account

Cart

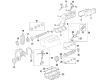

OEM Saturn Rod Bearing

Engine Connecting Rod Bearing- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

8 Rod Bearings found

Saturn Bearing Set Part Number: 93171031

$73.13 MSRP: $96.83You Save: $23.70 (25%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Bearing, Connecting Rod; Rod Bearing; Bearings; Bearing Kit, Engine Connecting Rod

Saturn Bearings Part Number: 12636003

$10.36 MSRP: $17.07You Save: $6.71 (40%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Bearing Kit, Connecting Rod; Bearing Kit, Engine Connecting Rod; Bearing, Engine Connecting Rod

- Replaces: 12598657

Saturn Bearing Set, Green Line Part Number: 12591093

$42.83 MSRP: $72.96You Save: $30.13 (42%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Bearing Kit, Connecting Rod; Rod Bearing; Bearings; Bearing Kit, Engine Connecting Rod

- Replaces: 21018825

Saturn Bearing Set Part Number: 93184458

$43.93 MSRP: $68.80You Save: $24.87 (37%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Bearing Kit, Connecting Rod; Rod Bearing; Bearings; Bearing Kit, Engine Connecting Rod

Saturn Bearings Part Number: 89060553

$6.22 MSRP: $9.74You Save: $3.52 (37%)Product Specifications- Other Name: Bearing Kit, Connecting Rod; Rod Bearing; Bearing Kit, Engine Connecting Rod

- Replaces: 12586085

Saturn Bearings Part Number: 21007487

Product Specifications- Other Name: Bearing, Engine Connecting Rod; Rod Bearing

Saturn Bearing Set Part Number: 12582410

Product Specifications- Other Name: Bearing, Engine Connecting Rod; Rod Bearing

Saturn Bearing Set Part Number: 9192965

Product Specifications- Other Name: Bearing Kit; Main Bearing; Bearing Kit, Engine Crankshaft Main

Saturn Rod Bearing

Choose OEM Rod Bearing, you're making the optimal decision for superior quality and perfect performance. You can feel confident because each component goes through stringent quality checks. Every part is carefully built to comply with Saturn's factory specifications. You'll enjoy a smooth, worry-free installation that fits just right. At ChevyPartsGiant.com, you'll find it easy to get top-quality OEM Saturn Rod Bearing. You can shop at highly competitive prices and protect your budget. All our genuine Saturn parts include a dependable manufacturer's warranty. You'll also appreciate our straightforward return policy and swift delivery services for extra convenience.

Saturn Rod Bearing offers an inexpensive cushion between the connecting rod and crankshaft journal that offers low friction and shields the sensitive engine components but allows the free rotation of the energetic power plant. Saturn cars were known to have a dent resistant polymer panels, sharp styling, and high quality paint that ensured that they were fresh long after their competitors had been forgotten. Lost foam casting shedding weight in the engine blocks that provided Saturn with a nimble feel and improved fuel figures. The factory, which was established in 1991 was dedicated and made vehicles that owners described as being very reliable and almost family like brand spirit. Body cladding made of plastic deflected the effects of shopping carts and the corrosion-resistance finishes took less time to repair dents, which made the brand remain valuable in the applied market. Such pragmatic benefits combined with creative production shaped the devotional fan club that continues to worship Saturn to this day. Rod Bearing in this setup is an accuracy insert between a rod and crank, which maintains an oil film and, with each stroke of power, carries every stroke smoothly. To install a Saturn Rod Bearing, it is optimal to start with disconnecting the battery, emptying the oil, and the next step is to drop the oil pan to disclose the internals. Take out the rod cap, make a note and wipe off the worn insert. Clean journals and rods, assure that new Rod Bearing size fits, and a little fresh oil on it. Insert, align tangs, plastigage or micrometer to check clearance, apply assembly lube, torque to spec, spin crank to get a sense of smooth motion, pan re-inserted, oil refilled and battery returned.