ChevyParts

My Garage

My Account

Cart

OEM 2000 Chevrolet Tracker Drive Belt

Serpentine Belt- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

6 Drive Belts found

2000 Chevrolet Tracker Serpentine Belt Part Number: 30000283

$5.68 MSRP: $62.86You Save: $57.18 (91%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Belt, Drive; Serpentine Belt Drive Kit; Accessory Drive Belt; Drive Belt; V-Belt; Power Steering Belt

- Item Weight: 0.50 Pounds

- Item Dimensions: 6.3 x 3.5 x 0.5 inches

- Condition: New

- Fitment Type: Direct Replacement

- SKU: 30000283

- Warranty: This genuine part is guaranteed by GM's factory warranty.

2000 Chevrolet Tracker Serpentine Belt Part Number: 30016435

$26.14 MSRP: $59.84You Save: $33.70 (57%)Product Specifications- Other Name: AC Belt; Power Steering Belt; A/C Belt

- Replaces: 30019502, 30020417

- Item Weight: 1.30 Pounds

- Item Dimensions: 10.1 x 8.1 x 6.9 inches

- Condition: New

- SKU: 30016435

- Warranty: This genuine part is guaranteed by GM's factory warranty.

2000 Chevrolet Tracker Serpentine Belt Part Number: 30005514

$13.55 MSRP: $31.02You Save: $17.47 (57%)Product Specifications- Other Name: Belt, Water Pump; Serpentine Belt Drive Kit; Accessory Drive Belt; Drive Belt; V-Belt; Fan Belt; Power Steering Belt; Water Pump Belt

- Replaces: 30002603

- Item Weight: 0.50 Pounds

- Item Dimensions: 9.6 x 2.7 x 13.1 inches

- Condition: New

- SKU: 30005514

- Warranty: This genuine part is guaranteed by GM's factory warranty.

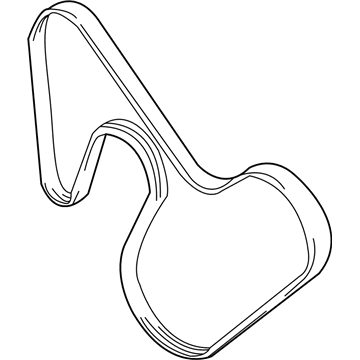

2000 Chevrolet Tracker Serpentine Belt Part Number: 30027112

$10.42 MSRP: $70.70You Save: $60.28 (86%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Serpentine Belt Drive Kit; Accessory Drive Belt; Drive Belt; V-Belt; Fan Belt; Belt, Drive

- Replaces: 30020683

- Item Weight: 0.60 Pounds

- Item Dimensions: 14.4 x 6.2 x 0.9 inches

- Condition: New

- Fitment Type: Direct Replacement

- SKU: 30027112

- Warranty: This genuine part is guaranteed by GM's factory warranty.

2000 Chevrolet Tracker Serpentine Belt Part Number: 30026873

$6.75 MSRP: $6.76You Save: $0.01 (1%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Belt, Water Pump, A/C Compressor, Generator, Power Steering Pump; Serpentine Drive Kit; Accessory Drive Belt.; Fan Belt; Power Steering Belt; Belt, Drive

- Replaces: 30021607

- Item Weight: 0.60 Pounds

- Item Dimensions: 15.5 x 3.8 x 0.9 inches

- Condition: New

- Fitment Type: Direct Replacement

- SKU: 30026873

- Warranty: This genuine part is guaranteed by GM's factory warranty.

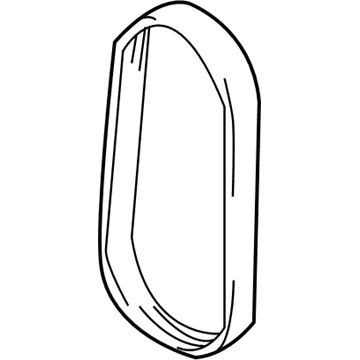

2000 Chevrolet Tracker Serpentine Belt Part Number: 91174492

Product Specifications- Other Name: Belt, Fan; Serpentine Belt Drive Kit; Accessory Drive Belt; Drive Belt; V-Belt; Power Steering Belt; Belt, Drive

- Item Weight: 0.40 Pounds

- Item Dimensions: 7.2 x 7.1 x 0.8 inches

- Condition: New

- Fitment Type: Direct Replacement

- SKU: 91174492

- Warranty: This genuine part is guaranteed by GM's factory warranty.

2000 Chevrolet Tracker Drive Belt

With a comprehensive array of OEM 2000 Chevrolet Tracker Drive Belt, from fuel pumps to door handles, our website is a one-stop-shop for your needs. All our genuine 2000 Chevrolet Tracker Drive Belt are backed by the manufacturer's warranty and are offered at competitive prices in the market. Rest assured, you can shop with complete confidence.

2000 Chevrolet Tracker Drive Belt Parts Questions & Experts Answers

- Q: How to replace the drive belt for the cooling fan on 2000 Chevrolet Tracker?A: The starting point for Drive Belt replacement of the cooling fan requires disconnecting the negative Battery Cable. First adjust the arriving bolt along with the pivot bolt so you can relieve tension from the fan belt through tension bolt rotation in a contrary direction. You need to remove the four fan nuts while using another wrench to stabilize the fan shaft with great attention to avoid the Radiator. Severely the cooling fan connection from its attachment point on the pulley hub then extract the fan belt. When installing a new fan belt position the fan at a distance from the pulley hub before fitting then fasten the fan to the hub by applying 4 fan nuts while using a wrench for fan shaft support until tightening the nuts reaches 11 nm (97 inch lbs.). Place the fan belt properly on the pulleys followed by a clockwise rotation of the tension bolt to reach a specific belt deflection range of 4 - 5 mm (0.16 - 0.20 inch) for new belts or 5 - 7 mm (0.20 - 0.27 inch) for used belts under 10 kg (22 lbs.) of tension force. The adjusting and pivot bolts should be tightened to 45 nm torque setting maintaining the proper fan belt tension throughout the procedure. Reinstall the negative Battery Cable then tighten the Battery Cable bolt to 15 nm (11 ft. Lbs.).