ChevyParts

My Garage

My Account

Cart

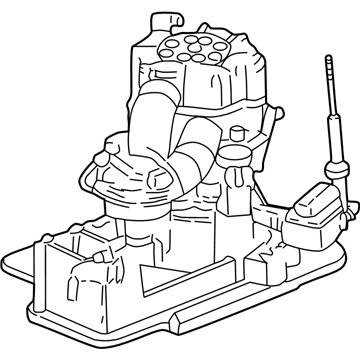

OEM GMC Savana 2500 Secondary Air Injection Pump

Secondary Smog Air Injection Pump- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

1 Secondary Air Injection Pump found

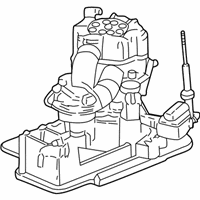

GMC Savana 2500 A.I.R. Pump Part Number: 12568324

$187.65 MSRP: $381.15You Save: $193.50 (51%)Ships in 1 Business Day

GMC Savana 2500 Secondary Air Injection Pump

Want to cut long-term maintenance and repair costs? Choose OEM Secondary Air Injection Pump. Those parts deliver top durability you can trust. On our site, you'll find a huge catalog of genuine GMC Savana 2500 parts. Prices are unbeatable, so you can keep more in your pocket. Every OEM GMC Savana 2500 Secondary Air Injection Pump includes a manufacturer's warranty. You can also get an easy return policy that keeps buying risk free. Fast delivery, get your car on the road quickly. It's simple to search, compare, and order. Stop guessing about quality or fit. Order today and save with parts that last.

GMC Savana 2500 Secondary Air Injection Pump Parts and Q&A

- Q: How to service the Secondary Air Injection Pump on GMC Savana 2500?A:The air injection pump servicing process starts by disconnecting all electrical connectors from the air pump together with the solenoid valve and Relay then removing the brace from the tender and cowl. The servicing of the air injection pump begins by removing the hose clamp from the shut-off valve hose then disconnecting the hose from the shut-off valve. Start by detaching the vacuum line from the solenoid valve followed by removal of the assembly hold-down bolt and then the block to remove the air pump assembly . Remove the rubber mounting posts from the air pump by releasing them before you disconnect the hoses (3,14) from the pump assembly and finally remove the pump itself from the place. To install the air pump position it on the rubber mounting posts while hooking up hoses (3,14) to the pump. Place the air pump assembly inside the vehicle then install the assembly hold-down block along with bolt which requires a torque of 25.0 n.m (18 lb ft). Fix the hose to the shut-off valve and fasten it with a hose clamp. Reestablish power flow through the electrical connector to the air pump as well as the solenoid valve and Relay before attaching the diagnostic trouble code (DTC) vacuum line to the solenoid valve. Close with step the brace installation to both fender and cowl before inspecting system operation.