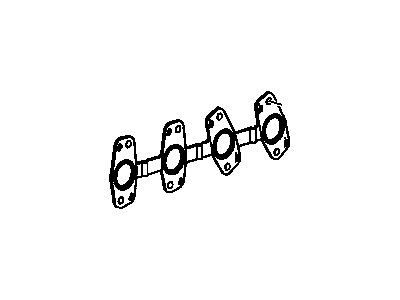

To remove the lower Intake Manifold, one should first remove the negative Battery Cable and breather at the air cleaner outlet duct along with their respective retaining wingnut, and disconnect the iat sensor harness connection. Next, remove the air cleaner outlet duct from Throttle Body, the accelerator cable from Throttle Body and the accelerator control cable bracket as well as disconnect the cruise control cable from throttle shaft and accelerator cable bracket if so equipped. Remove the vacuum hose from the Intake Manifold if built in a/c, from the power Brake Booster Vacuum Hose, and drain the cooling system. Unbolt the radiator inlet hose, heater hose, and water pump inlet hose from the Intake Manifold. Remove the fuel meter body assembly, evap canister purge solenoid valve, manifold air pressure (MAP) sensor, exhaust gas recirculation (EGR) valve, ignition coil, ignition control module (ICM), generator, idle air control (IAC) motor, throttle position (TP) sensor, a/c compressor cutoff switch if available and a/c clutch switch if available, and engine coolant temperature (ECT) sensor. Unclip the engine wire harness clips, pull the harness out of the way, and unsecure the accelerator cable bracket from the Throttle Body and Intake Manifold but leave the cables connected to the bracket. Loose the pcv hose assembly from the Intake Manifold and valve rocker arm cover, the evap canister purge solenoid valve, and the sparkplug wire harness retainer off the EGR Valve inlet pipe. Unscrew the clamp bolt that's connected to the egr inlet pipe and pull the pipe away from the intake and exhaust manifolds, and the Distributor. One must disconnect the fuel supply and return pipes that are located behind the Intake Manifold while avoiding the discharge of the refrigerant. To access the rear left front bolt for the Intake Manifold, remove the Drive Belt, loosen the nut for the power steering pump rear bracket, secondary air injection (AIR) reactor pipe bracket nut if equipped, nut of the power steering pump rear bracket and in the front of the engine. Smack the bolts and nut on the power steering pump mounting bracket while you flip off at the a/c compressor and chat along with power steering pump still on the bracket, then scoot the bracket laying on the bracket eradicate to the bolt up front achieve on the Intake Manifold. Unplug the ect sensor wire connector if available, and unbolt the lower Intake Manifold bolts. The Intake Manifold can also be taken out as an assembly; do not remove specific component unless service is required and do not let dirt or debris enter it the fuel system. Unscrew and remove the lower inlet manifold gaskets and clean the entrance manifold in cleaning solvent, and dry with compressed air at the same time checking the condition of the gasket sealing surfaces and restricted egr system passages , restricted cooling system passages , cracks, or damage, and damaged to keened threaded bolt holes respectively. Replace if needed, and use a 4.0 mm (0.157 inch) patch of adhesive gm p/n12346141 or equivalent on each end of the cylinder head of the lower Intake Manifold gasket while wet. Mount the lower Intake Manifold gaskets onto the cylinder head using the gasket locator pins and apply gm p/n 12346141 or equivalent adhesive at a 5mm (0.197 inch) wide bead size to the top of the front and rear engine block with the adhesive bead extending 13mm (0.50 inch) onto each lower Intake Manifold gaskets. Mount the lower Intake Manifold on the engine block, and apply threadlock gm p/n 12345382 or equivalent if you are going to reuse the lower Intake Manifold bolts and install the bolts. Follow the right tightening sequence and specifications for torque. First pass to 3 nm (27 inch lbs.), second pass to 12 nm (106 inch lbs.) and final pass to 15n.m (11 ft. Lbs.). Mount the power steering pump mount bracket loosely and bolt with nuts and tighten to 41 nm (30 ft. Lbs.). Install the air reactor pipe bracket nut where fitted, it should be tightened to 41 nm [30 ft. Lbs.] then install the Drive Belt, fuel supply and return pipes, with a correct positioning of the engine to number one cylinder top dead center for Distributor installation. To mark the position of the crankshaft balancer, remove the number one Spark Plug, rotate the crankshaft to the compression stroke, align the reference marks of the crankshaft balancer with the alignment marks of the front cover, and reinstall the number one Spark Plug together with the Distributor. In the evap canister purge solenoid valve: install EGR Valve inlet pipe to the intake and exhaust manifolds, tighten nut for Intake Manifold 25 nm (18 ft. Lbs.), in exhaust manifold tighten nut 30 nm (22 ft. Lbs), and clamp bolt 25 nm (18 ft. Lbs). Reconnect both the Spark Plug wire harness retainer, pcv hose assembly, accelerator cable and cruise control cable bracket to the Throttle Body, with nuts tightened to 9 nm (80 inch lbs.) nuts and both the accelerator cable bracket to the Intake Manifold and Throttle Body, with studs and nuts tightened to 12 nm (106 inch lbs.). Mount the engine wiring harness, install the clips, hook up the iac motor ,tp sensor, a/c compressor cutoff switch if necessary, a/c clutch switch if necessary, ect sensor ,fuel meter body assembly, evap canister purge solenoid valve, map sensor, egr valve, ignition coil, icm, and generator. On our minivan we also connected the Brake Booster Vacuum Hose, vacuum to intake if we had a/c, water pump inlet hose, heater hose, and radiator inlet hose. Cruise control cable if we have it and accelerator cable to the Throttle Body making sure that the cable would seat correctly. Carefully install the air cleaner outlet duct to the Throttle Body and maf sensor, tightening hose clamp to 4 nm (32 inch lbs.), connect the iat sensor harness connector and leave air cleaner duct installed with retaining wingnut set to 2 nm (18 inch lbs.). Finally, join the breather tube to the air cleaner outlet duct, fill the cooling system, and reconnect the battery negative cable.

Posted by ChevyPartsGiant Specialist