ChevyParts

My Garage

My Account

Cart

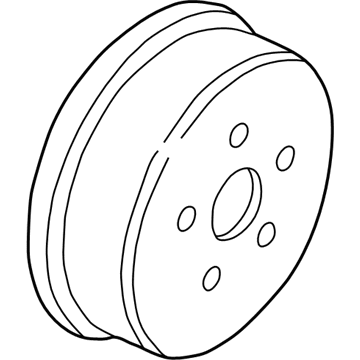

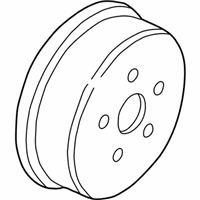

OEM Buick Regal Brake Drum

- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

2 Brake Drums found

Buick Regal Brake Drum Part Number: 88957254

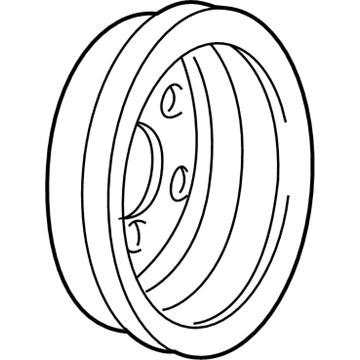

Buick Regal Brake Drum, Rear Part Number: 1249146

Buick Regal Brake Drum

Want to cut long-term maintenance and repair costs? Choose OEM Brake Drum. Those parts deliver top durability you can trust. On our site, you'll find a huge catalog of genuine Buick Regal parts. Prices are unbeatable, so you can keep more in your pocket. Every OEM Buick Regal Brake Drum includes a manufacturer's warranty. You can also get an easy return policy that keeps buying risk free. Fast delivery, get your car on the road quickly. It's simple to search, compare, and order. Stop guessing about quality or fit. Order today and save with parts that last.

Brake Drum of Buick Regal has responsibility for slowing down and for stopping the car through friction that is made between the brake shoe and the drum. A special cast iron is used to create the drum together with the wheel and axle construction, ensured the brake lining press on the inner side of the drum once brakes are applied. This friction produces heat to eventually slow or stop the vehicle's motion and effectively brings the transportation means to a hold. In particular, the Brake Drum is rather critical for maintaining the proper functioning of the braking system in Buick Regal vehicles.

Buick Regal Brake Drum Parts and Q&A

- Q: How to service and repair the brake drum on Buick Regal?A:Currently performing routine brake system maintenance does not require drum refinishing until at least one of these conditions exists: extreme corrosion, pitting, cracking, heat spots, severe bluing discoloration, or scoring beyond maximum specification or radial runout beyond maximum specification. Check brake drums for these conditions before measuring their diameter when you remove tire and wheel assemblies. The J 41013 Rotor/Drum Flange Resurfacing Kit removes all corrosion from the brake drum flange before you follow the manufacturer's instructions to mount the brake drum on the lathe by ensuring vibration dampening attachments are properly installed. Check the witness mark while operating the lathe by placing the cutting tool against the brake drum friction surface. A properly mounted drum will show witness marks that extend for at least three-quarters of its surface area. The drum refinish process should follow lathe manufacturer guidance while you inspect each cut for diameter deviations and must replace the drum if refinishing extends the drum beyond specified tolerances. Use the specified speeds for your refinishing project when working on non-directional surfaces and use 120 grit aluminum oxide sandpaper if you have a non-directional finishing tool or 150 grit aluminum oxide sandpaper with a sanding block as an alternative when no tool is available. Wipe friction surfaces using denatured alcohol or equivalent brake cleaner after you apply the finish to them. Clear all remaining brake drum from the lathe machine then clean the wheel bearing flange with the J 42450-A Hub Cleaning Kit because not doing so may create lateral runout and brake system pulsation.