ChevyParts

My Garage

My Account

Cart

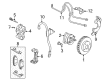

OEM Cadillac Eldorado Brake Disc

Disc Rotor- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

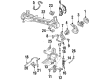

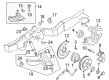

7 Brake Discs found

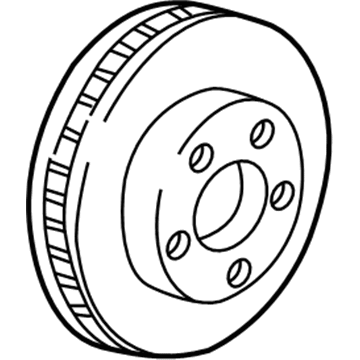

Cadillac Eldorado Brake Rotor, Front Part Number: 19174917

$50.14 MSRP: $89.54You Save: $39.40 (44%)Ships in 1-3 Business Days

Cadillac Eldorado Rotor, Front Part Number: 19202731

Cadillac Eldorado Brake Rotor Part Number: 25526230

Cadillac Eldorado Rotor, Front Part Number: 18060235

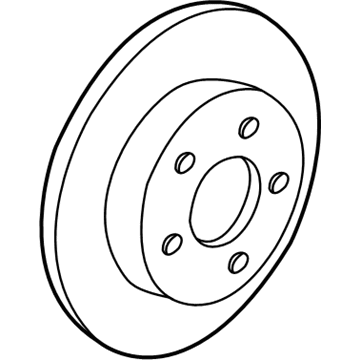

Cadillac Eldorado Rotor, Rear Part Number: 18021768

Cadillac Eldorado Brake Rotor Part Number: 18017505

Cadillac Eldorado Brake Rotor, Front Part Number: 19174912

$49.39 MSRP: $88.20You Save: $38.81 (44%)

Cadillac Eldorado Brake Disc

Want to cut long-term maintenance and repair costs? Choose OEM Brake Disc. Those parts deliver top durability you can trust. On our site, you'll find a huge catalog of genuine Cadillac Eldorado parts. Prices are unbeatable, so you can keep more in your pocket. Every OEM Cadillac Eldorado Brake Disc includes a manufacturer's warranty. You can also get an easy return policy that keeps buying risk free. Fast delivery, get your car on the road quickly. It's simple to search, compare, and order. Stop guessing about quality or fit. Order today and save with parts that last.

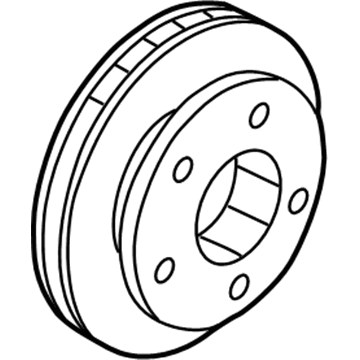

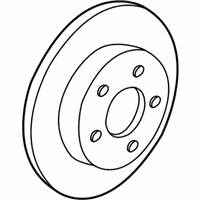

Brake Disc on Cadillac Eldorado cars is the disc brake's component that delivers the surface area on which the brake pads compress to enable slowing down or halting the car. Located on the axle or hub, the rotor turns with the wheel and when the brake is applied the hydraulic pressure pushes the caliper to squeeze the pads on the rotor. This design is more effective than the drum brakes and especially when used with the vented rotos which possess the cooling fins. Since the beginning of Cadillac Eldorado production, it has used different kinds of Brake Discs such as the solid type and the vented type. The smooth surfaced rotors are mostly used by small nondesigned vehicles while the vented rotors improve on cooling and performance. This is important because otherwise rotors may face such problems as scoring, warping or excessive runout which all influence braking capabilities. Brake Discs require frequent checking and replacement for Cadillac Eldorado to provide its peak performance.

Cadillac Eldorado Brake Disc Parts and Q&A

- Q: What tools are required to service and repair the Brake Disc on Cadillac Eldorado?A:These are the tools needed to service and repair brake discs: In order to service the brake disc two tools are needed: Rotor Resurfacing Kit (J 41013) and Wheel Hub Resurfacing Kit (J 42450-A). Rotor Resurfacing Kit (J 41013) and Wheel Hub Resurfacing Kit (J 42450-A). Brake disc refinishing should only occur as part of routine service when any combination of excessive corrosion, cracks, excessive bluing, scoring beyond maximum specifications, lateral runout, or thickness variation occurs. Measurement of disc surface wear and thickness should take place on each brake disc. Refinish the wheel bearing flange using Rotor Resurfacing Kit (J 41013) and resurface the brake disc mating surface and mounting face using Wheel Hub Resurfacing Kit (J 42450-A). Mount the brake disc to the lathe while following the manufacturer's directions and verify that all connections remain clean. Use the lathe to advance cutting tools toward the disc mate surfaces while observing the witness mark to confirm tool position. Re-mount when required following the lathe manufacturer's instructions to execute disc refinishing procedures with repeated thickness checks. Brake discs with thickness above the minimum tolerance require replacement after refinishing. When executing non-directional finishing operations utilize the recommended speed of the lathe together with 120 grit aluminum oxide sandpaper when equipped with a directional tool or 150 grit aluminum oxide sandpaper alongside a sanding block as an alternative. All friction surfaces require cleaning with denatured alcohol or brake cleaner equivalent until you remove the disc from the lathe.

- Q: How to replace the rear brake disc on Cadillac Eldorado?A:The first step to replace a rear Brake Disc includes tire and wheel removal. The brake caliper needs heavy mechanic's wire or an equivalent mounting support during disconnection from its mount with the hydraulic flexible brake hose in place to prevent brake fluid leaks and brake hose damage. You must remove first the brake caliper and bracket from the vehicle while placing the caliper assembly outside the disc before removing the Brake Disc. Cleaning all rust and contaminants off wheel bearing flanges together with the components that mate with disc surfaces will stop brake pulsation and increase lateral runout. The wheel hub resurfacing kit from j 42450-a effectively removes all surface rust and corrosion that exists on wheel hubs. Put the new Brake Disc onto the wheel bearing flange using the wheel studs before you install the Brake Caliper Bracket assembly and lastly secure the tire and wheel assembly.