ChevyParts

My Garage

My Account

Cart

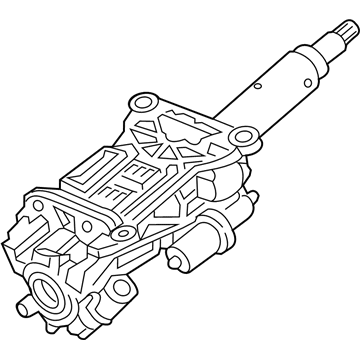

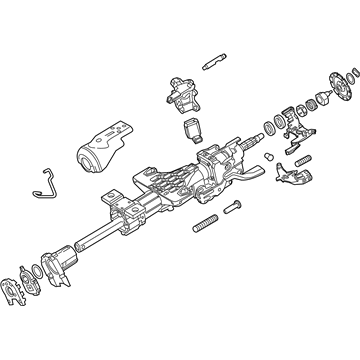

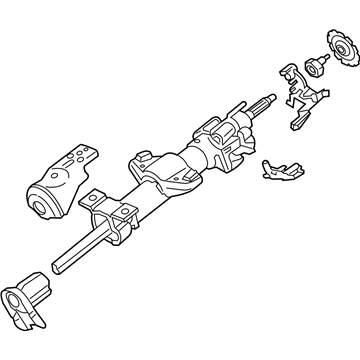

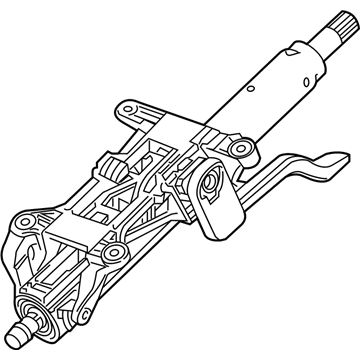

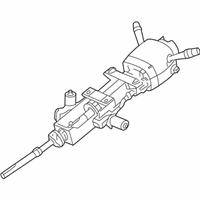

OEM Cadillac Steering Column

Steering Column Tilt- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

150 Steering Columns found

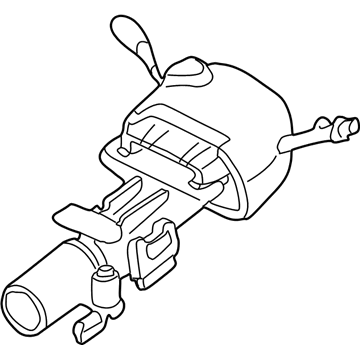

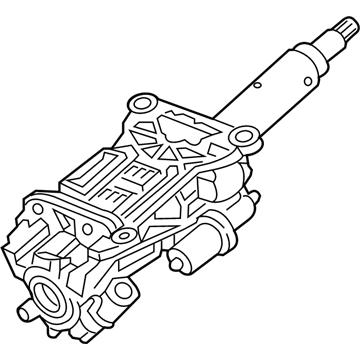

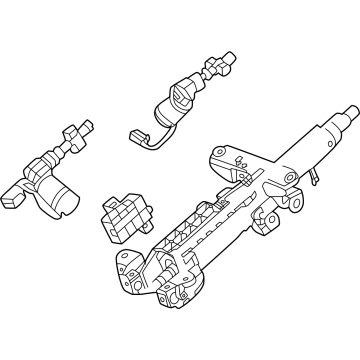

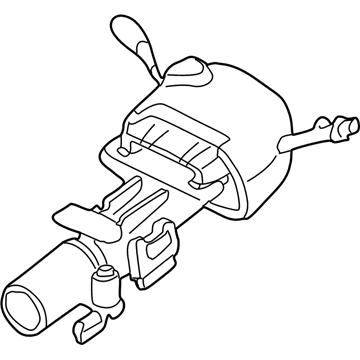

Cadillac Steering Column Part Number: 26095153

$857.86 MSRP: $1598.91You Save: $741.05 (47%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Column, Steering

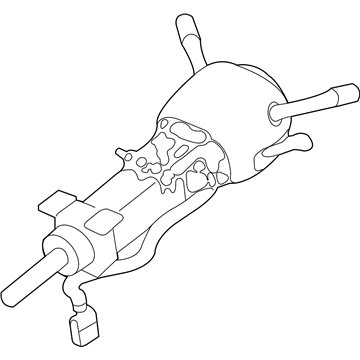

Cadillac Steering Column Part Number: 85118028

$163.08 MSRP: $256.59You Save: $93.51 (37%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Column Assembly; Column, Steering

- Replaces: 84069903, 23146400, 23162258, 23483787, 22961279, 22993009, 19418833, 84143307, 84533023

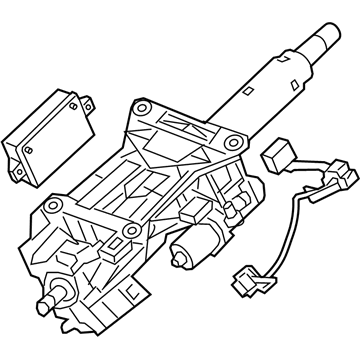

Cadillac Steering Column Part Number: 84703390

$128.72 MSRP: $202.53You Save: $73.81 (37%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Column Assembly; Column, Steering

- Replaces: 84625116, 84450602, 84401498

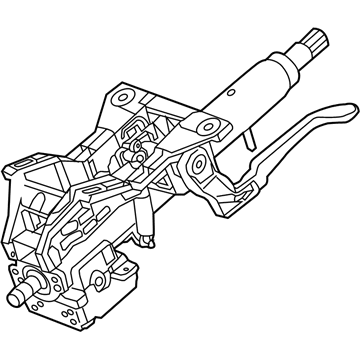

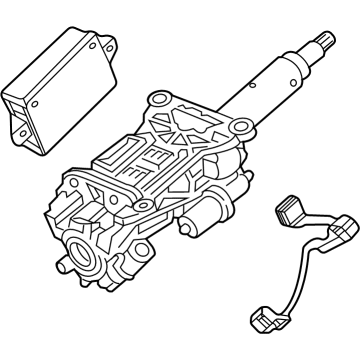

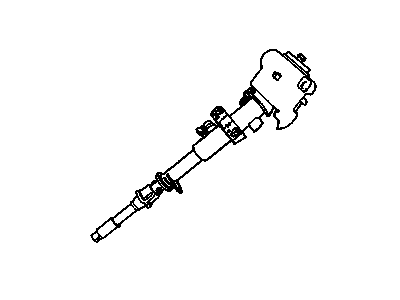

Cadillac Steering Column Part Number: 84634676

$1128.79 MSRP: $1783.73You Save: $654.94 (37%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Column Assembly-Steering (Repair); Column, Steering

Cadillac Steering Column Part Number: 84511957

$869.43 MSRP: $1480.21You Save: $610.78 (42%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Column Assembly-Steering (Repair); Column, Steering

- Replaces: 23381951, 84047767, 23494790, 22834632, 23354101

Cadillac Steering Column Part Number: 84511955

$890.65 MSRP: $1516.31You Save: $625.66 (42%)Product Specifications- Other Name: Column Assembly-Steering (Repair)

- Replaced by: 23381949

Cadillac Steering Column Part Number: 85544104

$265.77 MSRP: $418.18You Save: $152.41 (37%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Column Assembly; Column, Steering

Cadillac Steering Column Part Number: 84703165

$387.57 MSRP: $609.84You Save: $222.27 (37%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Column Assembly

- Replaced by: 85561699

Cadillac Steering Column Part Number: 84066366

$348.33 MSRP: $547.95You Save: $199.62 (37%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Column Assembly

Cadillac Steering Column Part Number: 23304592

$172.93 MSRP: $272.09You Save: $99.16 (37%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Column Assembly

- Replaced by: 23340983

Cadillac Steering Column Part Number: 26384411

$281.40 MSRP: $442.78You Save: $161.38 (37%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Column Assembly; Column, Steering

Cadillac Steering Column Part Number: 23146401

$174.19 MSRP: $276.56You Save: $102.37 (38%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Column Assembly

- Replaced by: 84143308

Cadillac Steering Column Part Number: 86528971

$139.29 MSRP: $219.16You Save: $79.87 (37%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Column Assembly-Steering (Repair); Column, Steering

Cadillac Steering Column Part Number: 84900872

$122.58 MSRP: $192.87You Save: $70.29 (37%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Column Assembly; Column, Steering

Cadillac Steering Column Part Number: 26084860

Product Specifications- Other Name: Column; Column, Steering

Cadillac Steering Column Part Number: 26089530

Product Specifications- Other Name: Column; Column, Steering

Cadillac Steering Column Part Number: 26098683

Product Specifications- Other Name: Column; Column, Steering

Cadillac Steering Column Part Number: 25744451

Product Specifications- Other Name: Column, Steering; Column Assembly

Cadillac Steering Column Part Number: 26083611

Product Specifications- Other Name: Column Assembly; Column, Steering

Cadillac Steering Column Part Number: 20835059

Product Specifications- Other Name: Column, Steering; Control Module

- Replaces: 25797804

| Page 1 of 8 |Next >

1-20 of 150 Results

Cadillac Steering Column

Want to cut long-term maintenance and repair costs? Choose OEM Steering Column. Those parts deliver top durability you can trust. On our site, you'll find a huge catalog of genuine Cadillac parts. Prices are unbeatable, so you can keep more in your pocket. Every OEM Cadillac Steering Column includes a manufacturer's warranty. You can also get an easy return policy that keeps buying risk free. Fast delivery, get your car on the road quickly. It's simple to search, compare, and order. Stop guessing about quality or fit. Order today and save with parts that last.

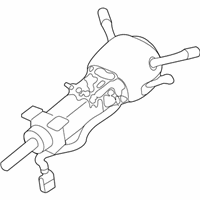

Cadillac Steering Column Parts Questions & Experts Answers

- Q: What should be inspected in accidents with potential steering column damage on Cadillac CTS?A:A vehicle involved in an accident will need inspection when it suffers frame damage or major body or sheet metal damage or an impacted Steering Column or deployed supplemental inflatable restraint system may have a damaged or misaligned Steering Column. During the inspection of Steering Column bracket assembly capsules ensure they are tightly fitted into their respective slots while evaluating any loose bracket behavior when manually pushed or pulled. According to the method of bracket connection to jacket assembly there are two scenarios for repair : a bracket substitution when capsules are not properly seated and bracket uses bolts or only replace the jacket assembly when capsules are not properly seated and the bracket uses welding techniques. Jacket assembly replacement must occur when measurements reveal dimensions outside specifications from the lower edge of upper jacket to the specified point on the lower jacket. Check if the bearing and adapter assembly tabs have been damaged while inspecting the Steering Shaft for sheared plastic areas. When sheared plastic appears on the Steering Shaft require a new replacement shaft. A Steering Shaft runout test occurs with a dial indicator alongside the wheel rotation to check wether any framework damage has caused shaft bending or if the runout exceeds 0.0625 inches (1.60 mm).

- Q: What should be inspected in accidents with potential steering column damage on Cadillac XLR?A:Vehicles that encounter accidents with frame-related damages along with significant body or sheet metal destruction or Steering Column impacts or supplemental inflatables activating will potentially suffer from Steering Column malfunctions. The Steering Column bracket assembly should receive an inspection of its capsules through verification of proper bracket slot seating while also inspecting loose tolerance when hand test is applied. When examining the bracket-to-jacket assembly connection and capsule seat position ensure replacement of either the bracket alone or the complete jacket assembly based on these findings. The measurement of distance must be performed to test jacket assembly collapse; any jacket assembly requiring replacement should have dimensions that fall outside of specifications. Survey the bearing and adapter assembly for a broken tab while looking for sheared plastic on the Steering Shaft; if sheared plastic exists replace the Steering Shaft. A frame-related Steering Shaft bend requires dial indicator evaluation of the Steering Shaft lower end to measure runout during wheel rotation when the runout must stay below 1.60 mm (0.06 in).

- Q: What should be inspected to determine if a steering column is damaged or misaligned after an accident on Cadillac Escalade?A:Sustained frame damage together with major sheet metal deformations and collisions that strike the Steering Column or activate supplementary air bags will potentially cause damage to Steering Column alignment. Test each capsule in the Steering Column bracket assembly while inspecting its secure seating position in the slot system. Use hand activation to check for free movement or looseness. Replace the bracket when installed by bolts to the jacket assembly but change the entire jacket assembly if welding holds the bracket in place. Checking the lower edge of the upper jacket against a specific position on the lower jacket requires measurement to evaluate possible collapse. Stated specifications guide when to replace the jacket assembly. First detach the sir coil from the Steering Column before letting it drop freely while performing shaft rotation. A visual examination of the Steering Shaft should look for plastic shearing; replacement of the Steering Shaft becomes necessary when shearing occurs. A dial indicator measurement at the bottom of the Steering Shaft determines if frame damage exists by tracking the shaft runout during steering wheel rotation. The acceptable runout measurement is 0.0625 inches (1.60 mm).