ChevyParts

My Garage

My Account

Cart

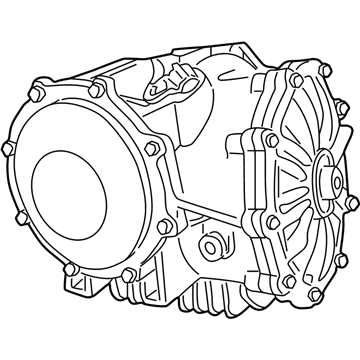

OEM Cadillac XLR Differential

Front Differential- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

15 Differentials found

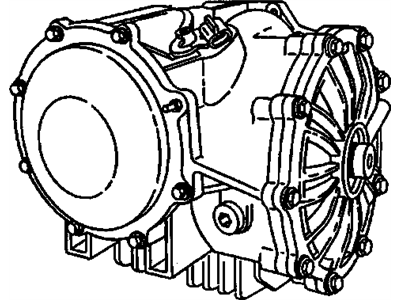

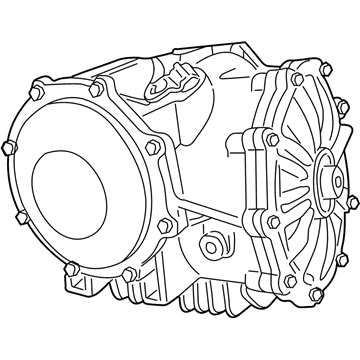

Cadillac XLR Differential Part Number: 19180957

$249.63 MSRP: $1345.71You Save: $1096.08 (82%)Ships in 1-2 Business DaysCadillac XLR Housing Part Number: 89060165

$930.05 MSRP: $1229.10You Save: $299.05 (25%)Cadillac XLR Differential Part Number: 88996687

$1069.76 MSRP: $1376.78You Save: $307.02 (23%)Ships in 1-3 Business DaysCadillac XLR Carrier Assembly Part Number: 24235244

Cadillac XLR Carrier Assembly Part Number: 24242241

Cadillac XLR Carrier Part Number: 24235844

Cadillac XLR Carrier Assembly Part Number: 24235841

Cadillac XLR Carrier Assembly Part Number: 24235245

Cadillac XLR Carrier Assembly Part Number: 24234596

Cadillac XLR Differential Part Number: 19133252

Cadillac XLR Differential Part Number: 19133230

Cadillac XLR Housing Part Number: 19133220

Cadillac XLR Differential Part Number: 19132907

Cadillac XLR Differential Part Number: 19132818

Cadillac XLR Carrier Assembly Part Number: 12586582

Cadillac XLR Differential

Want to cut long-term maintenance and repair costs? Choose OEM Differential. Those parts deliver top durability you can trust. On our site, you'll find a huge catalog of genuine Cadillac XLR parts. Prices are unbeatable, so you can keep more in your pocket. Every OEM Cadillac XLR Differential includes a manufacturer's warranty. You can also get an easy return policy that keeps buying risk free. Fast delivery, get your car on the road quickly. It's simple to search, compare, and order. Stop guessing about quality or fit. Order today and save with parts that last.

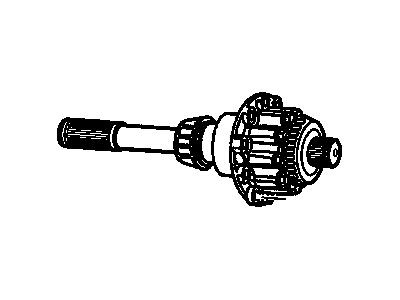

The Differential is a critical element that largely contributes to the improvement of the Cadillac XLR series which comprises numerous models ranging from 2003 to 2009. This differential enables the rotational speeds of the drive wheels to be unique, which is essential to achieve fluid cornering and maximum grip; thus, the safety of driving is enhanced. The Cadillac XLR normally uses bevel gearset differential; this mechanism ensures uneven distribution of the wheels' velocities in cases of turning and causes less wear of the tires and less stress for the powertrain. Depending on the model, Cadillac has applied both open and limited-slip differentials (LSD) kinds of differentials that are different from each other in their properties. Thus, the LSD, in particular, can be noted by offering unequal tire torque distribution as it increases the ability to grip on slippery ground, which determines control. Active electronics could also be incorporated into the cars enhancing the performance and efficiency of Cadillac models. Cadillac XLR is designed to reflect luxurious style and also equiped with many facilities including the heated leather seats, V8 Northstar powerful engine and the differential is considered as the part of the engineering masterpiece of Cadillac XLR. The Differential enhances torque management and steering to boost the safety measure of the car and bring the Cadillac into the limelight within the market. Lastly, we have the Differential which it is crucial to the company to accomplish the intended performance of the roadster and feel of a luxury automobile for every model.

Cadillac XLR Differential Parts Questions & Experts Answers

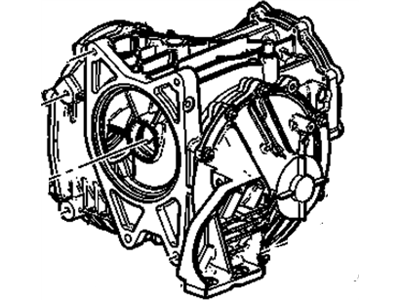

- Q: What steps should be taken to clean and inspect the differential case components and associated parts for damage and wear on Cadillac XLR?A:Clean the differential case components in solvent and check them for cracks, damage, escort to the bolt hole threads, unaccustomed wear, scoring and grooves in clutch pack area, scored and damaged case side bearing mounting flanges. Afterwards remove the solvent and use a soft cloth to clean the gears and the shafts thoroughly. Verify the presence of chips. Presence of cracks, pitting or heat discoloration, unusual wear or wear aside into the pin bores or side gear, wear or grooving or scoring on the side gear pin wear scored or worn side gear washers or itself wear or grooves on the output gear splines damage to ring gear threaded bolt holes or damage to the bolt holes in the ring gear and also the vehicle speed sensor reluctor ring lobes. Examine the shafts of unusual wear, grooved, worn or damaged splines, and damaged C-clip grooves. Clean the discs & plates with solvent and check them for unusual novos (wear, scoring, or grooves on the separator plate friction surfaces), uneven wear donessed friction matter on friction plates, bent or warped plates or discs, worn, scored, or collapsed bellville washer. Examine the bearing rollers and cups for pitting, scoring, grooves, severe wear, and other damage, and also look for heat discoloration, which can vary from faint yellow to dark blue reflecting overload or improper lubrication; any bearings or cups appearing discoloured by heat are to be replaced. Furthermore, check on bent bearing cages and damaged bearing cages.