ChevyParts

My Garage

My Account

Cart

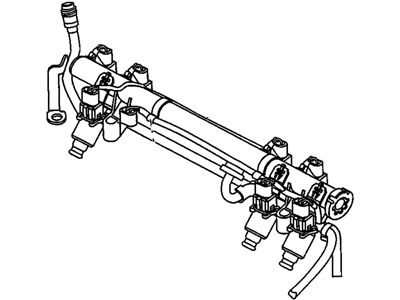

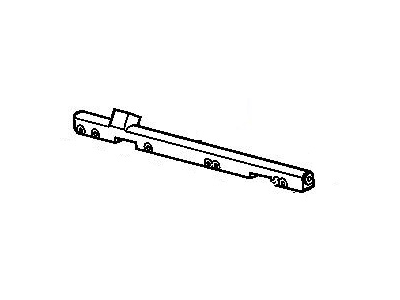

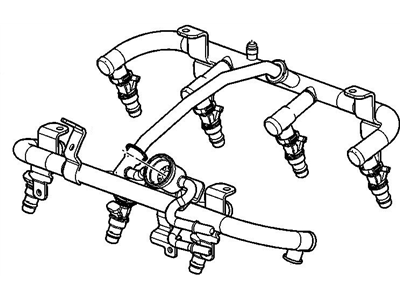

OEM Chevrolet Express 3500 Fuel Rail

Engine Fuel Rail- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

18 Fuel Rails found

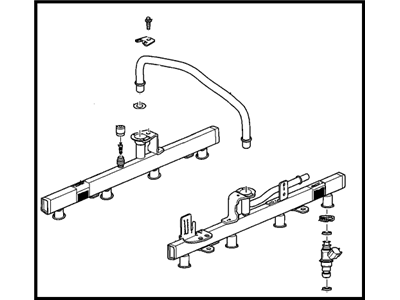

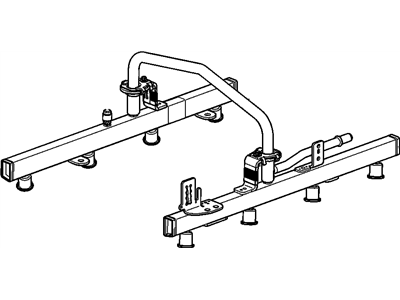

Chevrolet Express 3500 Fuel Rail Part Number: 97361352

$351.85 MSRP: $714.61You Save: $362.76 (51%)

Chevrolet Express 3500 Fuel Rail Part Number: 97361353

$336.68 MSRP: $683.83You Save: $347.15 (51%)

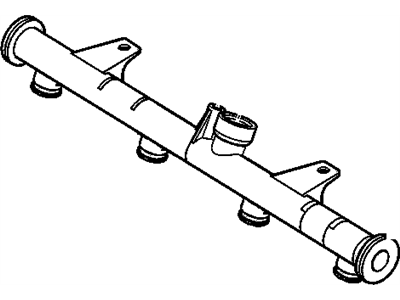

Chevrolet Express 3500 Fuel Rail Part Number: 17113695

$104.95 MSRP: $327.45You Save: $222.50 (68%)Ships in 1-2 Business Days

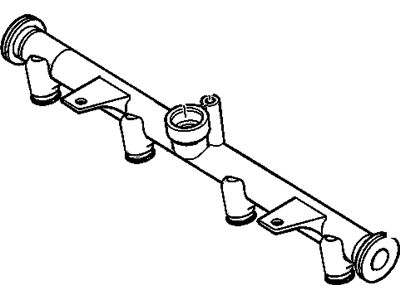

Chevrolet Express 3500 Fuel Rail Part Number: 12660710

$184.53 MSRP: $374.78You Save: $190.25 (51%)Ships in 1-2 Business Days

Chevrolet Express 3500 Fuel Rail Part Number: 12660709

$198.77 MSRP: $359.76You Save: $160.99 (45%)Ships in 1-2 Business Days

Chevrolet Express 3500 Fuel Rail Part Number: 12651989

$350.28 MSRP: $711.44You Save: $361.16 (51%)Ships in 1-2 Business Days

Chevrolet Express 3500 Fuel Rail Part Number: 12620532

$324.97 MSRP: $660.04You Save: $335.07 (51%)Ships in 1-2 Business Days

Chevrolet Express 3500 Fuel Rail Part Number: 12602113

$114.68 MSRP: $232.93You Save: $118.25 (51%)Ships in 1-2 Business DaysChevrolet Express 3500 Fuel Rail Part Number: 55510921

$459.87 MSRP: $828.60You Save: $368.73 (45%)Ships in 1-3 Business DaysChevrolet Express 3500 Fuel Rail Part Number: 12729466

$117.50 MSRP: $238.66You Save: $121.16 (51%)Chevrolet Express 3500 Fuel Rail Part Number: 12729464

$117.50 MSRP: $238.66You Save: $121.16 (51%)Ships in 1-2 Business DaysChevrolet Express 3500 Fuel Rail Part Number: 12707886

$107.92 MSRP: $192.72You Save: $84.80 (44%)Ships in 1-2 Business DaysChevrolet Express 3500 Fuel Rail Part Number: 12707885

$107.92 MSRP: $192.72You Save: $84.80 (44%)Ships in 1-2 Business DaysChevrolet Express 3500 Fuel Rail Part Number: 12621668

$198.77 MSRP: $359.76You Save: $160.99 (45%)Ships in 1-2 Business Days

Chevrolet Express 3500 Fuel Rail Part Number: 17120039

Chevrolet Express 3500 Fuel Rail Part Number: 17113696

Chevrolet Express 3500 Fuel Rail Part Number: 12575055

Chevrolet Express 3500 Fuel Rail Part Number: 89018109

Chevrolet Express 3500 Fuel Rail

Want to cut long-term maintenance and repair costs? Choose OEM Fuel Rail. Those parts deliver top durability you can trust. On our site, you'll find a huge catalog of genuine Chevrolet Express 3500 parts. Prices are unbeatable, so you can keep more in your pocket. Every OEM Chevrolet Express 3500 Fuel Rail includes a manufacturer's warranty. You can also get an easy return policy that keeps buying risk free. Fast delivery, get your car on the road quickly. It's simple to search, compare, and order. Stop guessing about quality or fit. Order today and save with parts that last.

Chevrolet Express 3500 Fuel Rail Parts Questions & Experts Answers

- Q: How to replace the fuel rail assembly on Chevrolet Express 3500?A:The procedure to replace the Fuel Rail assembly starts with removing both the engine cover and the air cleaner resonator outlet duct. Use gm x-30a engine spray along with its packaging guidelines to clean the Fuel Rail assembly without submerging it in any cleaning solution. You can find an eight-digit code that serves for both servicing and parts replacement on the Fuel Rail assembly. Take off the accelerator control cable and cruise control cable from the cable bracket before you remove the upper engine wire harness retainer nut and Throttle Body. The evap purge valve harness connector should be disconnected before setting the upper engine wire harness to the side. Remove fuel pressure from the system before marking all electrical connectors with the correct injector correspondence details for appropriate firing sequence after reinstallation. Disconnection of multec 2 fuel injector connectors should be handled without pliers because they can cause damage to the connectors. The fuel injector connector disconnection requires pulling up the connector position assurance (CPA) on the injector connector followed by pushing the tab on the injector connector in and finally releasing the cpa. After disconnecting the injector connectors perform the same procedure for all the connectors followed by safely removing the fuel feed and return pipes from the Fuel Rail. The first step requires users to cut the fuel pressure regulator vacuum line followed by a loosening of the crossover tube to right Fuel Rail retainer screw before removing the Fuel Rail bolts to eventually remove the Fuel Rail. Extract the lower o-ring seals which belong to the injectors. Smoother installation of new fuel injector lower o-ring seals takes place when applying clean engine oil before putting them onto each injector. The process begins by removing the retaining clip attaching screw together with the crossover pipe retainer from the right-hand Fuel Rail. Afterwards separate the crossover pipe rail and o-ring. Insert the right Fuel Rail crossover pipe after placement of the lubricated o-ring with clean engine oil. Begin your work on the attaching screw for the retaining clip manually to stop thread destruction before you mount the crossover pipe retainer and attach its screw to install the Fuel Rail. Start by wrapping threads of the Fuel Rail bolts with a 5 mm band of gm p/n 12345382 threadlock. Then apply bolts and secure them at 10 n.m torque. Use 3.8 n.m torque to secure the screw while reconnecting the fuel pressure regulator vacuum line and fuel feed and return pipes to the Fuel Rail. Attach the fuel injector electrical connectors to their specific injectors while observing the correct firing sequence and ensuring wire harness flexibility. Next install the upper engine wire harness followed by connecting the evap purge solenoid connector along with its retainer nut that should be tightened to 5.5 n.m. Afterward restore the accelerator control cable along with cruise control cable installation of air cleaner resonator outlet duct and engine cover. The last step requires igniting the engine while keeping it off for 2 seconds and then shutting it off for 10 seconds followed by an ignition check to detect fuel leaks.