ChevyParts

My Garage

My Account

Cart

OEM Chevrolet K3500 Universal Joint

U-Joint- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

3 Universal Joints found

Chevrolet K3500 Universal Joints Part Number: 23104840

$36.45 MSRP: $88.98You Save: $52.53 (60%)

Chevrolet K3500 Universal Joints Part Number: 89059111

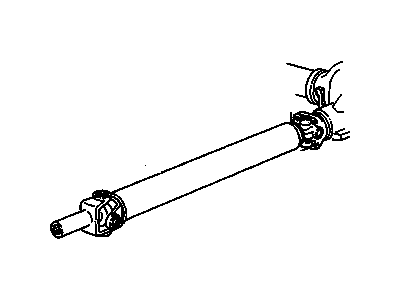

$163.83 MSRP: $273.43You Save: $109.60 (41%)Ships in 1-2 Business Days

Chevrolet K3500 Universal Joints Part Number: 88964413

$196.62 MSRP: $328.19You Save: $131.57 (41%)Ships in 1-2 Business Days

Chevrolet K3500 Universal Joint

Want to cut long-term maintenance and repair costs? Choose OEM Universal Joint. Those parts deliver top durability you can trust. On our site, you'll find a huge catalog of genuine Chevrolet K3500 parts. Prices are unbeatable, so you can keep more in your pocket. Every OEM Chevrolet K3500 Universal Joint includes a manufacturer's warranty. You can also get an easy return policy that keeps buying risk free. Fast delivery, get your car on the road quickly. It's simple to search, compare, and order. Stop guessing about quality or fit. Order today and save with parts that last.

They are heavily used in ChevrolesK3500 Universal Joint is one of the most essential parts in Chevroles that embody the brand's reliability and performance within K3500 series. As the link between the driveshaft and the differential, the Universal Joint makes necessary movement accompanying the vehicle's suspension of highway irregularities. This is well appreciated as far as efficiency and safety is concerned; thereby making it possible for the K3500 to perform some herculean task. Chevrolet K3500 universal joint also incorporates deep-rolled cross and needle bearings housed in strong steel cups that makes it strong and durable. Depending on the model of the K3500, different styles of Universal would have been fitted, such as sealed Universal Joints that prevent the need for grease, and others with grease zerks that allow for easy relubrication. Such ability is important as it guarantees that Universal Joint will be efficient for work and other fun related activities. Interestingly, the K3500 is famed for manufacturing strong built trucks with some Vortec engines; in this regard, a good Universal Joint plays a significant role in keeping the vehicles' performance intact. Given the emission control, which is much more elaborated than in other Chevrolet models, and the D-rings that can be adjusted at different heights, the Chevrolet K3500 attracts attention among other vehicles in the market. In conclusion, this paper seeks to argue that the Universal Joint is a vital component in the overall improvement of the K3500 and categorical to the lineage of strength and ingenuity.

Chevrolet K3500 Universal Joint Parts Questions & Experts Answers

- Q: How to replace the universal joints (External Snap Ring Type) on Chevrolet K3500?A:Support the entire propeller shaft on a press table so one end is up and one is down; after that, indicate the spots where you will connect the transmission and rear axle using marks. Pull out the snap ring by gripping its end with pliers; if one is difficult to remove, tap the bearing cup to remove the pressure. Attach the side with the Universal Joint to a socket of 30 mm (1 1/8 inch) size and press out the lower bearing cup using j9522-3. If the cup is stuck inside, raise the cross, slide the j9522-5 between the seal and the stuck cup and keep pressing. Rotate the propeller shaft to push out the opposite bearing cup, take out the cross and all pieces from the yoke and if you are changing the front Universal Joint, remove its bearing cups just like before. Check the grooves around the retaining ring and the bearing cup bores for dirt or corrosion and clean them as required. Before installing, take the bearings out of the new Universal Joint journals and apply grease to them. Partially affix one bearing cup into the yoke, rotate the yoke pin clockwise so the ear points down and slide the lacing cross in position until the trunnion seats in the cup. Set the bearing cup that goes on the yoke flush against it and then start the other side by setting the bearing cup so the trunnions are in line. While pushing in the opposite bearing cup, make sure the trunnions can rotate easily. If the gears are binding, immediately stop and check if they are not aligned. Keep pressing the bearing out until the groove for the retainer becomes apparent and then install the retainer with chassis grease if required to help it go on properly. When the retainer won't technically seat, use a dead blow hammer to tap the yoke with a firm stroke.