ChevyParts

My Garage

My Account

Cart

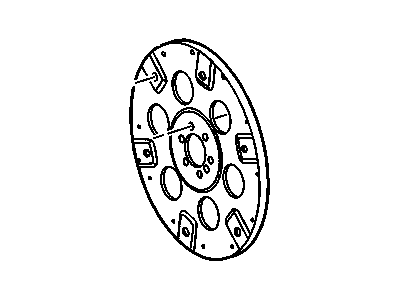

OEM Chevrolet Metro Flywheel

Clutch Flywheel- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

3 Flywheels found

Chevrolet Metro Drive Plate Part Number: 91173838

$96.57 MSRP: $178.38You Save: $81.81 (46%)Ships in 1-2 Business DaysChevrolet Metro Flywheel Part Number: 96064507

Chevrolet Metro Flywheel Part Number: 96062035

Chevrolet Metro Flywheel

Want to cut long-term maintenance and repair costs? Choose OEM Flywheel. Those parts deliver top durability you can trust. On our site, you'll find a huge catalog of genuine Chevrolet Metro parts. Prices are unbeatable, so you can keep more in your pocket. Every OEM Chevrolet Metro Flywheel includes a manufacturer's warranty. You can also get an easy return policy that keeps buying risk free. Fast delivery, get your car on the road quickly. It's simple to search, compare, and order. Stop guessing about quality or fit. Order today and save with parts that last.

Chevrolet Metro Flywheel Parts Questions & Experts Answers

- Q: How to service and repair the Flywheel on Chevrolet Metro?A:Before performing a Flywheel service and repair you must remove the transaxle which is attached to the engine. The removal of the clutch enables manual transaxle vehicle service. Check the ring gear for any evidence of wear as well as damage and cracking. Damage along with excessive wear and cracks on the surface where the Clutch Disc contacts will require replacement of the current Flywheel. Open several marks on the Flywheel and engine alignment and unscrew first the retaining bolts then remove the Flywheel with Crankshaft placement followed by the clutch Pilot Bearing from the Crankshaft. Use a suitable solvent to remove grease and dirt from all areas of the outer Flywheel surfaces. Install the clutch Pilot Bearing inside the Crankshaft before mounting the Flywheel while maintaining both the Flywheel-to-engine marks in alignment. Excessive sealant applied to the Flywheel retaining bolt threads should be avoided because overflown sealant may break the bolt during operation. The application of gm p/n 1234593 or equivalent on the Flywheel retaining bolt threads should be followed by installing the Flywheel retaining bolts to a torque of 95 nm (69 ft. Lbs.) for automatic transmissions and 78 nm (57 ft. Lbs.) for manual transmissions. The last process for manual-transaxle vehicles consists of attaching the clutch to the Flywheel followed by reattaching the transaxle to the engine.