ChevyParts

My Garage

My Account

Cart

OEM Chevrolet Silverado 1500 Classic Lash Adjuster

Lash Adjuster Lifter- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

1 Lash Adjuster found

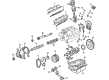

Chevrolet Silverado 1500 Classic Valve Lifters Part Number: 17122490

$37.49 MSRP: $61.75You Save: $24.26 (40%)Ships in 1-2 Business Days

Chevrolet Silverado 1500 Classic Lash Adjuster

Want to cut long-term maintenance and repair costs? Choose OEM Lash Adjuster. Those parts deliver top durability you can trust. On our site, you'll find a huge catalog of genuine Chevrolet Silverado 1500 Classic parts. Prices are unbeatable, so you can keep more in your pocket. Every OEM Chevrolet Silverado 1500 Classic Lash Adjuster includes a manufacturer's warranty. You can also get an easy return policy that keeps buying risk free. Fast delivery, get your car on the road quickly. It's simple to search, compare, and order. Stop guessing about quality or fit. Order today and save with parts that last.

Chevrolet Silverado 1500 Classic Lash Adjuster Parts Questions & Experts Answers

- Q: How to replace the Lash Adjusters on Chevrolet Silverado 1500 Classic?A:Begin valve lifter replacement by removing the Intake Manifold along with pushrods before placing all components in a rack for correct reinstallation. After removing valves' lifter pushrod guide bolts you need to position valve lifters vertically in the rack to retain their oil content before lifting them out. When lifters get stuck because of gum or varnish buildup you should use the valve lifter remover (J 3049-A) tool to help them come out. Rinse the valve lifter bores with cleaning solvent then use a shop towel to clean them before inspecting for severe wear or scoring. Replace your engine block if necessary. Before finalizing check the Camshaft for damage and wear while removing it for better evaluation. After inspection, clean activated lifters if necessary. During new lifter installation add lubricant to the rollers while reinstalled lifters must remain in their initial setup. After tightening the guide bolts to 16 nm (12 ft. Lbs.) you can proceed to mount the pushrods and Intake Manifold. A new engine starts with a normal slight ticking noise during its initial startup period. The noise can be eliminated by increasing engine rpm slightly.