ChevyParts

My Garage

My Account

Cart

OEM Chevrolet Silverado 3500 Classic Universal Joint

U-Joint- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

3 Universal Joints found

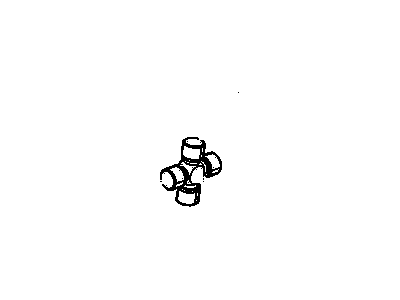

Chevrolet Silverado 3500 Classic Universal Joints Part Number: 23104840

$36.45 MSRP: $88.98You Save: $52.53 (60%)

Chevrolet Silverado 3500 Classic Universal Joints Part Number: 88964413

$196.62 MSRP: $328.19You Save: $131.57 (41%)Ships in 1-2 Business Days

Chevrolet Silverado 3500 Classic Universal Joints Part Number: 19121436

$130.13 MSRP: $308.44You Save: $178.31 (58%)Ships in 1-2 Business Days

Chevrolet Silverado 3500 Classic Universal Joint

Want to cut long-term maintenance and repair costs? Choose OEM Universal Joint. Those parts deliver top durability you can trust. On our site, you'll find a huge catalog of genuine Chevrolet Silverado 3500 Classic parts. Prices are unbeatable, so you can keep more in your pocket. Every OEM Chevrolet Silverado 3500 Classic Universal Joint includes a manufacturer's warranty. You can also get an easy return policy that keeps buying risk free. Fast delivery, get your car on the road quickly. It's simple to search, compare, and order. Stop guessing about quality or fit. Order today and save with parts that last.

Chevrolet Silverado 3500 Classic Universal Joint Parts Questions & Experts Answers

- Q: How to replace the universal joint with a nylon injected ring on Chevrolet Silverado 3500 Classic?A:Start your nylon injected ring replacement by obtaining two tools: U Joint Bearing Separator (J 9522-3) and U Joint Bearing Spacer Remover (J 9522-5). Keep the propeller shaft in level position when supporting it because contact with the tube can harm its structure. Place the lower yoke part of the universal joint onto a 30 mm (1 1/8 inch) socket before indicating the propeller shaft positions. Working with the U Joint Bearing Separator (J 9522-3) you should carefully cut through the plastic retaining ring on the lower bearing cup before pressing it out of the yoke ear. Use the U Joint Bearing Spacer Remover (J 9522-5) tool between the seal and bearing cup when the cup stays attached. Turn the propeller shaft to take away the other bearing cup as you note the slip yoke position in relation to the tube. Clean both bearing cup bores in the yoke ears along with all retaining ring grooves before assembly. Use a proper tool to remove all sheared plastic bits that remain in the grooves. Push a bearing cup into one yoke side then position the cross to align the trunnion freely before pressing the cup until it meets the yoke face. Do the same process using the second bearing cup and confirm the trunnions sit properly. Check the needle bearings for accurate alignment and force them toward the yoke until the bearing retainer groove moves out from the yoke. Push the bearing retainer into place using a dead blow hammer while inserting it to all the way home. You can apply chassis grease to the snap ring to simplify its installation steps.