ChevyParts

My Garage

My Account

Cart

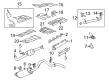

OEM Chevrolet Suburban 1500 Exhaust Manifold

Engine Exhaust Manifold- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

5 Exhaust Manifolds found

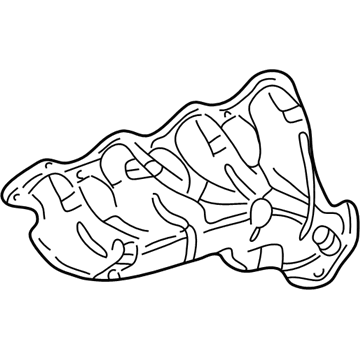

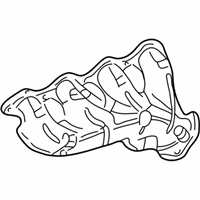

Chevrolet Suburban 1500 Exhaust Manifold, Driver Side Part Number: 12616285

$131.69 MSRP: $224.19You Save: $92.50 (42%)Chevrolet Suburban 1500 Exhaust Manifold Part Number: 12677665

$230.69 MSRP: $362.98You Save: $132.29 (37%)Ships in 1-2 Business Days

Chevrolet Suburban 1500 Exhaust Manifold

Want to cut long-term maintenance and repair costs? Choose OEM Exhaust Manifold. Those parts deliver top durability you can trust. On our site, you'll find a huge catalog of genuine Chevrolet Suburban 1500 parts. Prices are unbeatable, so you can keep more in your pocket. Every OEM Chevrolet Suburban 1500 Exhaust Manifold includes a manufacturer's warranty. You can also get an easy return policy that keeps buying risk free. Fast delivery, get your car on the road quickly. It's simple to search, compare, and order. Stop guessing about quality or fit. Order today and save with parts that last.

Chevrolet Suburban 1500 Exhaust Manifold Parts Questions & Experts Answers

- Q: How to replace the right exhaust manifold on Chevrolet Suburban 1500?A:The procedure to replace the right Exhaust Manifold requires lifting and suspending the vehicle before removing Exhaust Manifold pipe nuts and lowering the vehicle. Unscrew the Spark Plugs then break loose bolts(1,2,3) which secure the exhaust gas recirculation(EGR) valve pipe to the Intake Manifold and Cylinder Head and Exhaust Manifold. Mild force should be used to pull the egr valve pipe off the Intake Manifold before discarding both the gasket and o-ring seal. You should first detach the crossover bolt connecting the secondary air injection (AIR) check valve pipe (crossover) to the check valves while repositioning the hose spring clamps. After that, cut the check valve pipe (crossover) from the check valves only when replacement is needed. Start by removing the right Exhaust Manifold check valve pipe nuts and pipe (with check valve) as well as gasket followed by removing Exhaust Manifold bolts, manifold and gasket which needs discarding. The exhibition of the Exhaust Manifold requires bolt removal from both heat shield and shield components. Secure the Exhaust Manifold with heat shield and its bolts when needed then torque heat shield bolts to 9 nm (80 inch lbs.). Follow the designated torque values for Exhaust Manifold bolt torque while cleaning all threads of the Cylinder Head Exhaust Manifold bolt openings from debris. Apply threadlock gm p/n 12345493 or equivalent to a 5 mm (0.2 inch) wide band that covers the Exhaust Manifold bolt threads. Then install the new gasket with the Exhaust Manifold and bolts. Start by tightening the Exhaust Manifold bolts from the center to both sides with the torque sequence of 15 nm (11 ft. Lbs.) followed by 25 nm (18 ft. Lbs.). Use a flat punch tool to bend the exposed portion of Exhaust Manifold gasket sealant situated at the front of the right Cylinder Head. Connect a new air check valve pipe gasket and the nuts and pipe with check valve to the right Exhaust Manifold before tightening the nuts to 25 nm (18 ft. Lbs.). Position the hose spring clamps while you attach the air check valve pipe (crossover) to the check valves. Tighten the crossover bolt to 50 nm (37 ft. Lbs.). Getting a new o-ring seal ready with engine oil prevents leakage before installation within the egr valve pipe. The egr pipe then needs to be installed in the secured position. Use a criss-cross method to fasten the egr valve pipe bolts until tight while torquing the egr valve pipe to Intake Manifold bolt to 10 nm (89 inch lbs.), the egr valve pipe to Cylinder Head bolts to 50 nm (37 ft. Lbs.), as well as the egr valve pipe to Exhaust Manifold bolts to 30 nm (22 ft. Lbs.). Put the spark plugs in place and elevate the vehicle afterward installing the Exhaust Manifold pipe nuts and tightening them to 50 nm (37 ft. Lbs.) before returning it to ground level.