ChevyParts

My Garage

My Account

Cart

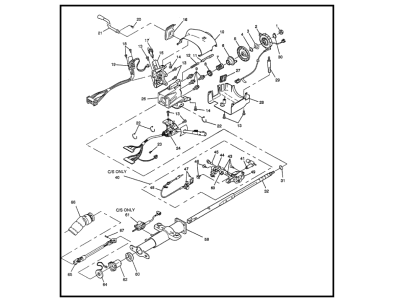

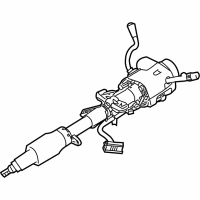

OEM GMC Savana 3500 Steering Column

Steering Column Tilt- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

31 Steering Columns found

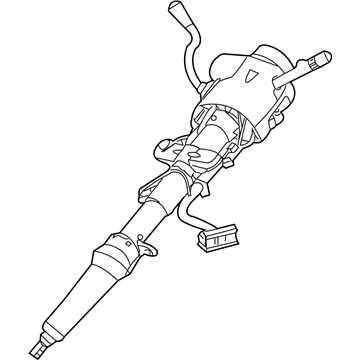

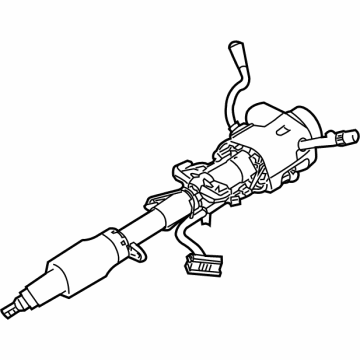

GMC Savana 3500 Steering Column Part Number: 84879212

$451.94 MSRP: $714.30You Save: $262.36 (37%)Ships in 1-3 Business DaysGMC Savana 3500 Column Assembly Part Number: 84501610

$464.60 MSRP: $734.18You Save: $269.58 (37%)Ships in 1-3 Business DaysGMC Savana 3500 Steering Column Part Number: 84879213

$479.06 MSRP: $757.18You Save: $278.12 (37%)Ships in 1-3 Business DaysGMC Savana 3500 Steering Column Part Number: 19368212

$464.60 MSRP: $734.18You Save: $269.58 (37%)GMC Savana 3500 Steering Column Part Number: 19180611

GMC Savana 3500 Steering Column Part Number: 19180634

GMC Savana 3500 Steering Column Part Number: 84501609

$527.41 MSRP: $833.56You Save: $306.15 (37%)GMC Savana 3500 Steering Column Part Number: 26060137

GMC Savana 3500 Steering Column Part Number: 26061646

GMC Savana 3500 Steering Column Part Number: 26068555

GMC Savana 3500 Steering Column Part Number: 26076234

GMC Savana 3500 Column Assembly Part Number: 26089105

GMC Savana 3500 Column Assembly Part Number: 26089109

GMC Savana 3500 Steering Column Part Number: 26093925

GMC Savana 3500 Steering Column Part Number: 19300155

GMC Savana 3500 Steering Column Part Number: 19180635

GMC Savana 3500 Steering Column Part Number: 19300154

GMC Savana 3500 Steering Column Part Number: 19300157

GMC Savana 3500 Jacket Part Number: 26046898

GMC Savana 3500 Steering Column Part Number: 19167202

| Page 1 of 2 |Next >

1-20 of 31 Results

GMC Savana 3500 Steering Column

Want to cut long-term maintenance and repair costs? Choose OEM Steering Column. Those parts deliver top durability you can trust. On our site, you'll find a huge catalog of genuine GMC Savana 3500 parts. Prices are unbeatable, so you can keep more in your pocket. Every OEM GMC Savana 3500 Steering Column includes a manufacturer's warranty. You can also get an easy return policy that keeps buying risk free. Fast delivery, get your car on the road quickly. It's simple to search, compare, and order. Stop guessing about quality or fit. Order today and save with parts that last.

GMC Savana 3500 Steering Column Parts and Q&A

- Q: What should be checked and replaced in accidents with potential steering column damage on GMC Savana 3500?A:Per industry standards the inspection of vehicles should be performed after all accidents that caused frame damage or major sheet metal damage or Steering Column impact or inflatable restraint system deployment whenfftention must be paid to the possible misalignment or damage to the column. The Steering Column bracket assembly contains capsules that should be examined to verify their complete insertion into the bracket slots while confirming their stability through manual touch and push-pull tests. The bracket should get replaced when bolted to the jacket assembly yet replacement of the jacket assembly is required when welded to it. The distance measurement from upper to lower jacket should be performed to confirm jacket assembly collapse; installing a new jacket assembly when measurements deviate from specifications. The instable restraint steering wheel module coil assembly needs to be removed from the Steering Column and left to dangle freely before turning the shaft so the coil assembly stays protected from damage. The technician must take out the inflatable restraint steering wheel module coil. The inspection of Steering Shaft for sheared injected plastic must lead to a new shaft installation when sheared plastic is detected. A dial indicator must check the lower end Steering Shaft runout while turning the wheel because any frame damage that might bend the shaft has a limit of 1.60 mm. The inflatable restraint steering wheel module coil needs to be installed as the final step of the installation process.

- Q: What should be inspected on those involved in accidents that may have a damaged or misaligned steering column on GMC Savana 3500?A:The Steering Column of vehicles experiences damage or misalignment when such vehicles suffer accidents leading to frame damage or encounters sheet metal damage or major body harm or impacts with the Steering Column while having their supplemental inflatable restraints system deployed. Check the Steering Column bracket assembly capsules by visually inspecting their proper seat in bracket slots then check bracket stability through manual hand tests. A bracket repair is required when capsules are not properly seated against the bracket and the connection is bolted to the jacket assembly. However, replacement of the entire jacket assembly is necessary when capsules are not secure but the bracket is welded to the jacket assembly. A measurement of the lower edge to defined point distance on the jacket assembly will help identify possible collapse where the assembly needs replacement if specifications are not met. Removing the inflatable restraint coil assembly from the Steering Column is essential before shaft rotation because letting it hang freely protects its coil structure from damage. The inspection must detect sheared injected plastic on the Steering Shaft since such damage requires a new Steering Shaft installation. A dial indicator should be used to check Steering Shaft runout at the lower end of the shaft through steering wheel rotation until the runout measurement reaches 1.60 mm (0.06 inch).