ChevyParts

My Garage

My Account

Cart

OEM 2001 GMC Savana 3500 Brake Disc

Disc Rotor- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

1 Brake Disc found

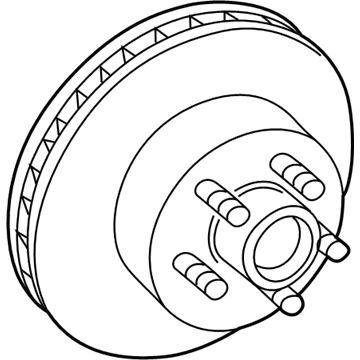

2001 GMC Savana 3500 Hub & Rotor, Front Part Number: 19202727

Product Specifications- Other Name: Rotor Assembly, Front Brake; Disc Brake Hardware Kit; Brake Rotor; Rotor; Rotor, Front And Rear Wheel Brake

- Position: Front

- Replaces: 15721421, 18060216, 19152697, 15981319

- Item Weight: 41.30 Pounds

- Item Dimensions: 14.2 x 13.3 x 7.2 inches

- Condition: New

- Fitment Type: Direct Replacement

- Require Quantity: 2

- SKU: 19202727

- Warranty: This genuine part is guaranteed by GM's factory warranty.

2001 GMC Savana 3500 Brake Disc

With a comprehensive array of OEM 2001 GMC Savana 3500 Brake Disc, from fuel pumps to door handles, our website is a one-stop-shop for your needs. All our genuine 2001 GMC Savana 3500 Brake Disc are backed by the manufacturer's warranty and are offered at competitive prices in the market. Rest assured, you can shop with complete confidence.

2001 GMC Savana 3500 Brake Disc Parts and Q&A

- Q: How to Replace the Brake Disc on 2001 GMC Savana 3500?A: To replace the Brake Disc, first lift and adequately support the vehicle. Take off the tire and wheel assembly by making sure you support the brake caliper with heavy mechanic's wire or equivalent if you pull it away from its mount while covering its hydraulic flexible brake hose as this helps to prevent damaging hose and brake fluid leakage. Then, take away the caliper from the mounting bracket again cushion with the heavy mechanic's wire; bear it in mind that when taking off the caliper from the bracket, do not cut off the hydraulic brake flexible hose. Move on to the removal of the wheel bearings and then the disc from the vehicle. If necessary, refinish the disc. Clean off any rust or corrosion at the disc to wheel mating face using the hub cleaning kit (J 42450-A) prior to reinstalling the disc onto the vehicle. Once the wheel bearings and seal are installed in place, it is suitable to install the brake caliper followed by the placement of the tire and assembly if it hasn't been done. Lastly, eliminate the safety stands, decrease the vehicle down, step the brake pedal down, and machine the brake discs and the brake pads at the front side.