ChevyParts

My Garage

My Account

Cart

OEM 2003 Chevrolet Impala Shock Absorber

Suspension Shock Absorber- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

2 Shock Absorbers found

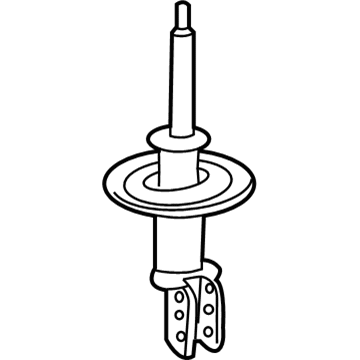

2003 Chevrolet Impala Strut Part Number: 88965467

$109.69 MSRP: $212.92You Save: $103.23 (49%)Product Specifications- Other Name: Strut Assembly, Front Suspension; Complete Strut and Shock Absorber Kit.; Strut, Front And Rear Suspension

- Position: Front

- Replaces: 22064733, 22064793, 22064745, 22064754, 22064750, 22064755, 22400002, 22064717, 22064784, 22064716, 22064774, 22064707

- Item Weight: 12.70 Pounds

- Item Dimensions: 24.3 x 9.6 x 7.6 inches

- Condition: New

- Fitment Type: Direct Replacement

- SKU: 88965467

- Warranty: This genuine part is guaranteed by GM's factory warranty.

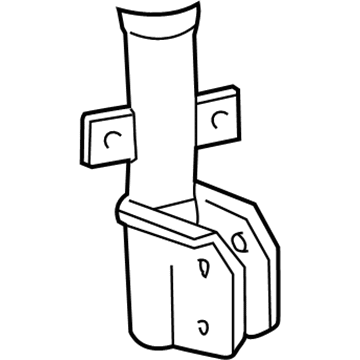

2003 Chevrolet Impala Strut Part Number: 88965469

Product Specifications- Other Name: Strut Assembly, Rear Suspension; Complete Strut Kit; Shock Absorber.; Strut, Front And Rear Suspension

- Position: Rear

- Replaces: 22064710, 22400003, 22064747, 15846384, 22064752, 22064751, 22064736, 15846385, 22064753

- Item Weight: 14.80 Pounds

- Item Dimensions: 9.3 x 8.3 x 25.2 inches

- Condition: New

- Fitment Type: Direct Replacement

- Require Quantity: 2

- SKU: 88965469

- Warranty: This genuine part is guaranteed by GM's factory warranty.

2003 Chevrolet Impala Shock Absorber

With a comprehensive array of OEM 2003 Chevrolet Impala Shock Absorber, from fuel pumps to door handles, our website is a one-stop-shop for your needs. All our genuine 2003 Chevrolet Impala Shock Absorber are backed by the manufacturer's warranty and are offered at competitive prices in the market. Rest assured, you can shop with complete confidence.

2003 Chevrolet Impala Shock Absorber Parts Questions & Experts Answers

- Q: What Tools Are Required to Service and Repair the Shock Absorber on 2003 Chevrolet Impala?A: The suspension strut service procedure requires these tools: A complete set of tools for suspensino strut servicing includes Strut Spring Compressor (J 34013-B), Damper Rod Clamp (J 34013-20), Alignment Rod (J 34013-197), Strut Compressor Adapter (J 34013-125) and Strut Compressor Lower Adapter (J 34013-971) and Strut Rod Nut Socket (J 42991). Strut Spring Compressor (J 34013-B), Damper Rod Clamp (J 34013-20), Alignment Rod (J 34013-197), Strut Compressor Adapter (J 34013-125), Strut Compressor Lower Adapter (J 34013-971), and Strut Rod Nut Socket (J 42991). First secure the strut from the vehicle onto the Strut Spring Compressor (J 34013-B) using wing nuts while positioning the wide adapter outboard. Secure the Strut Compressor Lower Adapter (J 34013-971) and Strut Compressor Adapter (J 34013-125) in their proper alignment which enables synchronous strut opening and closing. Attach the strut in both of these adapters before you close them using locking pins applied through holes in the Strut Spring Compressor (J 34013-B) and strut-mounting areas. Use the screw on the Strut Spring Compressor (J 34013-B) to rotate counterclockwise until the strut raises approximately 13 mm (0.50 in) equivalent to 3-4 complete turns. Use the Strut Rod Nut Socket (J 42991) to remove the nut as you hold the shaft using a T-45 TORX(r) bit. Discard the strut nut and release spring compression by turning the operating screw . Secure the strut back to the Strut Spring Compressor (J 34013-B) maintaining correct strut alignment throughout the process. Secure the Damper Rod Clamp (J 34013-20) to the strut shaft by full extension to keep the strut from retracting during compression. Fit the spring onto the strut following correct placement of the upper and lower spring seats before slowly conducting spring compression to see the threaded part of the strut shaft. Slide the Alignment Rod (J 34013-197) directly onto the shaft before installing a new strut nut. Check the rod's alignment throughout the process. Use the Strut Rod Nut Socket (J 42991) to tighten the strut rod to the upper mount at 75 N.m (55 lb ft) while simultaneously holding the shaft with a T-45 TORX(r) bit. When finished remove tools following their original placement order to extract the strut from Strut Spring Compressor (J 34013-B). Then install the strut seat back into the vehicle before adjusting wheel alignment measurements.