ChevyParts

My Garage

My Account

Cart

OEM 2003 GMC Safari Engine Mount

Engine Motor Mount- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

8 Engine Mounts found

2003 GMC Safari Motor Mount Part Number: 22188284

$51.94 MSRP: $88.43You Save: $36.49 (42%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Mount; Engine Mount Torque Strut; Engine Mount Bracket; Engine Mount; Side Mount; Front Mount; Mount, Engine Mount Dampening; Mount, Engine Mounting

- Replaces: 17989409, 22145879, 14082803, 17996145, 22112974, 22146241, 22145863, 17981702

- Item Weight: 2.30 Pounds

- Item Dimensions: 6.0 x 4.7 x 2.8 inches

- Condition: New

- Fitment Type: Direct Replacement

- SKU: 22188284

- Warranty: This genuine part is guaranteed by GM's factory warranty.

2003 GMC Safari Bracket, Passenger Side Part Number: 15999046

$43.37 MSRP: $67.92You Save: $24.55 (37%)Product Specifications- Other Name: Bracket, Engine Mounting; Engine Mount Bracket; Motor Mount

- Position: Passenger Side

- Item Weight: 2.10 Pounds

- Item Dimensions: 5.5 x 4.8 x 4.0 inches

- Condition: New

- Fitment Type: Direct Replacement

- SKU: 15999046

- Warranty: This genuine part is guaranteed by GM's factory warranty.

2003 GMC Safari Mount, Passenger Side Part Number: 15141594

Product Specifications- Other Name: Mount Assembly-Engine; Engine Mount Torque Strut; Engine Mount Bracket; Motor Mount; Mount, Engine Mounting

- Position: Passenger Side

- Replaces: 22112500

- Item Weight: 2.20 Pounds

- Item Dimensions: 5.6 x 4.7 x 2.6 inches

- Condition: New

- Fitment Type: Direct Replacement

- SKU: 15141594

- Warranty: This genuine part is guaranteed by GM's factory warranty.

2003 GMC Safari Mount, Driver Side Part Number: 15141593

Product Specifications- Other Name: Mount Assembly-Engine; Engine Mount Torque Strut; Engine Mount Bracket; Motor Mount; Mount, Engine Mount Dampening; Mount, Engine Mounting

- Position: Driver Side

- Replaces: 22112499

- Item Weight: 2.30 Pounds

- Item Dimensions: 5.4 x 4.6 x 2.5 inches

- Condition: New

- Fitment Type: Direct Replacement

- SKU: 15141593

- Warranty: This genuine part is guaranteed by GM's factory warranty.

2003 GMC Safari Bracket, Driver Side Part Number: 15697577

Product Specifications- Other Name: Bracket, Engine Mounting; Engine Mount Bracket; Motor Mount

- Position: Driver Side

- Item Weight: 2.10 Pounds

- Item Dimensions: 5.6 x 5.3 x 3.9 inches

- Condition: New

- Fitment Type: Direct Replacement

- SKU: 15697577

- Warranty: This genuine part is guaranteed by GM's factory warranty.

2003 GMC Safari Bracket, Driver Side Part Number: 15999045

Product Specifications- Other Name: Bracket, Engine Mounting; Engine Mount Bracket; Motor Mount

- Position: Driver Side

- Item Weight: 2.80 Pounds

- Item Dimensions: 8.2 x 6.5 x 5.3 inches

- Condition: New

- Fitment Type: Direct Replacement

- SKU: 15999045

- Warranty: This genuine part is guaranteed by GM's factory warranty.

2003 GMC Safari Bracket, Passenger Side Part Number: 15708672

Product Specifications- Other Name: Bracket, Engine Mounting; Engine Mount Bracket; Motor Mount

- Position: Passenger Side

- Item Weight: 2.10 Pounds

- Item Dimensions: 5.8 x 5.3 x 3.2 inches

- Condition: New

- Fitment Type: Direct Replacement

- SKU: 15708672

- Warranty: This genuine part is guaranteed by GM's factory warranty.

2003 GMC Safari Bracket Part Number: 15708673

Product Specifications- Other Name: Bracket, Engine Mounting; Engine Mount Bracket; Motor Mount

- Item Weight: 2.60 Pounds

- Item Dimensions: 6.9 x 7.1 x 3.7 inches

- Condition: New

- Fitment Type: Direct Replacement

- SKU: 15708673

- Warranty: This genuine part is guaranteed by GM's factory warranty.

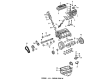

2003 GMC Safari Engine Mount

With a comprehensive array of OEM 2003 GMC Safari Engine Mount, from fuel pumps to door handles, our website is a one-stop-shop for your needs. All our genuine 2003 GMC Safari Engine Mount are backed by the manufacturer's warranty and are offered at competitive prices in the market. Rest assured, you can shop with complete confidence.

2003 GMC Safari Engine Mount Parts and Q&A

- Q: How to replace the right engine mount on 2003 GMC Safari?A: The first step to replace the right Engine Mount requires Battery Cable negation followed by vehicle elevation. You need to begin by taking away both the right front tire and right fender wheelhouse extension before extracting the Starter unit. Lift the engine using a jack at its square engine block tab until the Engine Mount clears through the hole. The removal requires you to remove the Engine Mount through-bolt with narrow nut. The right Engine Mount bracket requires access to its upper two bolts by entering through the fender wheelhouse area. The procedure for awd vehicles involves frame bolt removal of the Engine Mount while rwd vehicles need boltnut removal from Engine Mount to frame connection. For the awd vehicle install the Engine Mount onto frame bolts then tighten to 59 nm (44 ft. Lbs.) whereas for rwd vehicles install the right side Engine Mount along with bolts and nuts to the frame using 47 nm (35 ft. Lbs.) torque on the bolts and 42 nm (31 ft. Lbs.) torque on the nuts. Screw in the Engine Mount bracket to the motor while torquing bracket bolts to 64 nm (47 ft. Lbs.). You should position the engine at its lowest point to add the through-bolt and corresponding nut to the Engine Mount before applying a torque of 68 nm (50 ft. Lbs.). The abovementioned process terminates with Starter installation along with the right fender wheelhouse extension and right front tire while lowering the vehicle until battery negative cable reconnection.