ChevyParts

My Garage

My Account

Cart

OEM 2007 GMC Sierra 1500 TPMS Sensor

Tire Pressure Monitoring System Sensor- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

3 TPMS Sensors found

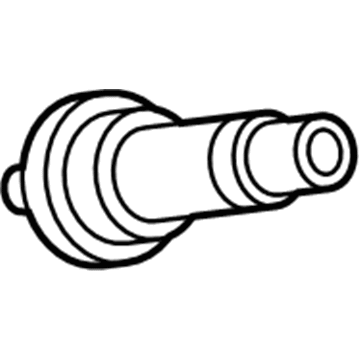

2007 GMC Sierra 1500 Tire Pressure Sensor, Black Part Number: 13598909

$11.19 MSRP: $21.02You Save: $9.83 (47%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Valve Kit, Tire Valve And Cover Lock; TPMS Sensor Service Kit; TPMS Sensor; Valve Stem; Repair Kit; Tire Sensor Valve; TPMS Sensor Valve Assembly; Tire Valve Kit; Vehicle Security & Safety.

- Replaces: 15263240, 19368646

- Item Weight: 0.40 Pounds

- Item Dimensions: 6.2 x 4.2 x 4.2 inches

- Condition: New

- Fitment Type: Direct Replacement

- SKU: 13598909

- Warranty: This genuine part is guaranteed by GM's factory warranty.

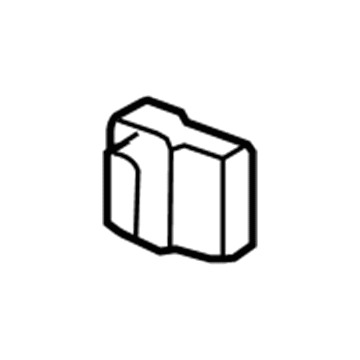

2007 GMC Sierra 1500 Control Module Part Number: 20803736

$70.29 MSRP: $193.25You Save: $122.96 (64%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Receiver, Door Lock Remote Control Inside; Receiver; Receiver, Door Electric And Vacuum Locks; Module, Tire Pressure; Harness, Dome Lamp

- Replaces: 15807815, 15857830, 25896540, 15946937, 25857326, 25856131, 25808836

- Item Weight: 0.40 Pounds

- Item Dimensions: 3.3 x 2.9 x 1.6 inches

- Condition: New

- Fitment Type: Direct Replacement

- SKU: 20803736

- Warranty: This genuine part is guaranteed by GM's factory warranty.

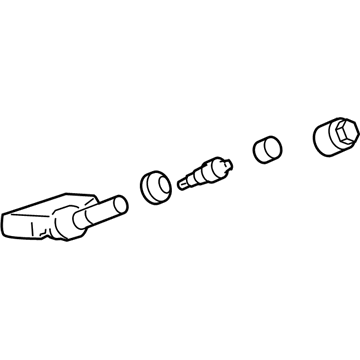

2007 GMC Sierra 1500 TPMS Sensor, Black Part Number: 13540600

$57.19 MSRP: $111.00You Save: $53.81 (49%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Sensor Assembly-Tire Pressure Indicator; Tire Pressure Sensor; Tire Sensor; Pressure Sensor; Sensor; Sensor, Vehicle Security & Safety; Sensor, Tire Pressure

- Replaces: 13598771, 15254101, 25799331, 13586335, 15825475, 15922396, 20923680, 23445327, 25920615, 22853741

- Condition: New

- SKU: 13540600

- Warranty: This genuine part is guaranteed by GM's factory warranty.

2007 GMC Sierra 1500 TPMS Sensor

With a comprehensive array of OEM 2007 GMC Sierra 1500 TPMS Sensor, from fuel pumps to door handles, our website is a one-stop-shop for your needs. All our genuine 2007 GMC Sierra 1500 TPMS Sensor are backed by the manufacturer's warranty and are offered at competitive prices in the market. Rest assured, you can shop with complete confidence.

2007 GMC Sierra 1500 TPMS Sensor Parts and Q&A

- Q: How to replace the TPMS Sensor (Clamp In Style) on 2007 GMC Sierra 1500?A: The process starts by lifting the vehicle onto a proper support type then disconnecting the tire/wheel assembly before proceeding. Position the sensor's both cap and valve onto a clean dry area and make sure to use only aluminum caps and nickel-plated valves to minimize corrosion. Use a bead breaking fixture at a 90-degree angle from the valve stem before inserting a tire iron or pry bar clockwise near the sensor body to pry the tire bead over the mounting/dismounting head. Operate the tire machine to turn the tire/wheel set clockwise so the tire bead crosses to the wheel rim's external side and apply this process again for the internal bead before extracting the tire from the wheel. All remaining tire sealant needs removal from the inner surfaces of tires and wheels. The procedure calls for sensor nut removal and sensor extraction. The installation requires cleaning of the grommet sealing area followed by sensor insertion into the wheel hole with the air passage directed toward the outside of the wheel while installing the sensor nut while positioning the sensor body parallel to the inside wheel surface then tightening it to 7 N.m (62 lb in). To resume tire installation start by positioning the mounting/dismounting head at right angles to the tire valve stem with both bead transitions oriented 45 degrees counterclockwise to the valve stem. The clockwise movement of the tire/wheel assembly directs the tire bead into the wheel rim followed by repeating the process for the outer bead. You must spin the tire/wheel combination faster than 20 mph or 32 km/h above the ground for at least ten seconds to operate the service replacement tire pressure sensor properly before reinstalling your vehicle's tire/wheel assembly.