ChevyParts

My Garage

My Account

Cart

OEM 2008 Cadillac CTS TPMS Sensor

Tire Pressure Monitoring System Sensor- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

5 TPMS Sensors found

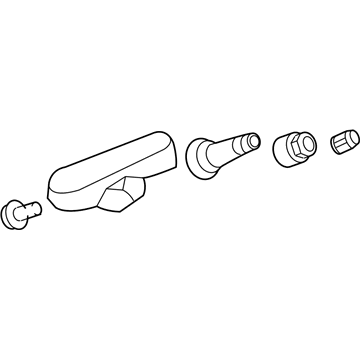

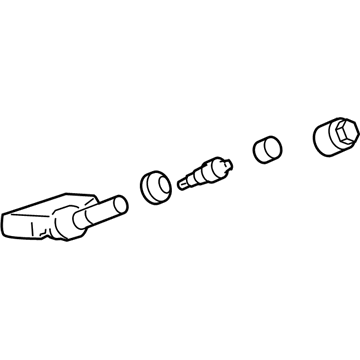

2008 Cadillac CTS Tire Pressure Sensor, Black Part Number: 13598909

$11.19 MSRP: $21.02You Save: $9.83 (47%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Valve Kit, Tire Valve And Cover Lock; TPMS Sensor Service Kit; TPMS Sensor; Valve Stem; Repair Kit; Tire Sensor Valve; TPMS Sensor Valve Assembly; Tire Valve Kit; Vehicle Security & Safety.

- Replaces: 15263240, 19368646

- Item Weight: 0.40 Pounds

- Item Dimensions: 6.2 x 4.2 x 4.2 inches

- Condition: New

- Fitment Type: Direct Replacement

- SKU: 13598909

- Warranty: This genuine part is guaranteed by GM's factory warranty.

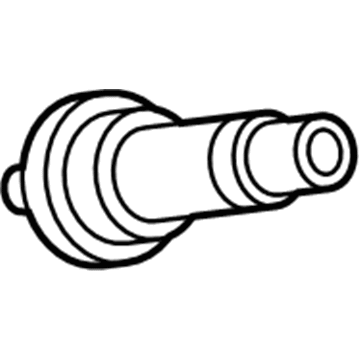

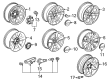

2008 Cadillac CTS TPMS Sensor Part Number: 25740352

$75.18 MSRP: $136.08You Save: $60.90 (45%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Sensor, Tire Pressure Indicator; Tire Pressure Monitoring System (TPMS) Sensor; Tire Pressure Sensor; Sensor, Tire Pressure

- Item Weight: 0.40 Pounds

- Item Dimensions: 3.6 x 2.1 x 1.4 inches

- Condition: New

- Fitment Type: Direct Replacement

- Require Quantity: 4

- SKU: 25740352

- Warranty: This genuine part is guaranteed by GM's factory warranty.

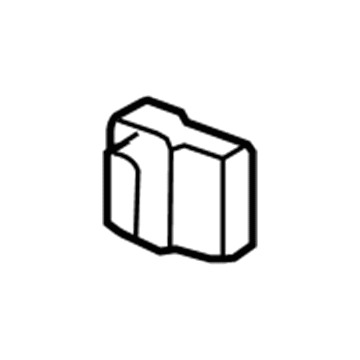

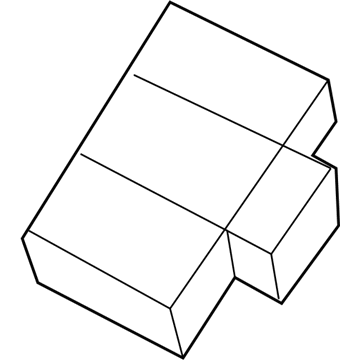

2008 Cadillac CTS Control Module Part Number: 20803736

$70.29 MSRP: $193.25You Save: $122.96 (64%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Receiver, Door Lock Remote Control Inside; Receiver; Receiver, Door Electric And Vacuum Locks; Module, Tire Pressure; Harness, Dome Lamp

- Replaces: 15807815, 15857830, 25896540, 15946937, 25857326, 25856131, 25808836

- Item Weight: 0.40 Pounds

- Item Dimensions: 3.3 x 2.9 x 1.6 inches

- Condition: New

- Fitment Type: Direct Replacement

- SKU: 20803736

- Warranty: This genuine part is guaranteed by GM's factory warranty.

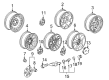

2008 Cadillac CTS TPMS Sensor, Black Part Number: 13540600

$57.19 MSRP: $111.00You Save: $53.81 (49%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Sensor Assembly-Tire Pressure Indicator; Tire Pressure Sensor; Tire Sensor; Pressure Sensor; Sensor; Sensor, Vehicle Security & Safety; Sensor, Tire Pressure

- Replaces: 13598771, 15254101, 25799331, 13586335, 15825475, 15922396, 20923680, 23445327, 25920615, 22853741

- Condition: New

- SKU: 13540600

- Warranty: This genuine part is guaranteed by GM's factory warranty.

2008 Cadillac CTS Control Module Part Number: 15866242

Product Specifications- Other Name: Module Assembly-Low Tire Pressure Indicator; Module, Tire Pressure

- Item Weight: 0.40 Pounds

- Item Dimensions: 8.2 x 4.1 x 2.1 inches

- Condition: New

- Fitment Type: Direct Replacement

- SKU: 15866242

- Warranty: This genuine part is guaranteed by GM's factory warranty.

2008 Cadillac CTS TPMS Sensor

With a comprehensive array of OEM 2008 Cadillac CTS TPMS Sensor, from fuel pumps to door handles, our website is a one-stop-shop for your needs. All our genuine 2008 Cadillac CTS TPMS Sensor are backed by the manufacturer's warranty and are offered at competitive prices in the market. Rest assured, you can shop with complete confidence.

2008 Cadillac CTS TPMS Sensor Parts Questions & Experts Answers

- Q: How to replace the TPMS Sensor on 2008 Cadillac CTS?A: The first step to replace the Tire Pressure Indicator Sensor requires appropriate vehicle raising on a support structure. Extract the tire/wheel assembly from its vehicular position. During tire removal from the wheel position the sensor cap alongside its valve on a sterile platform using aluminum for the cap and nickel plating on the valve to stop corrosion. The bead breaking fixture needs 90 degrees alignment to the valve stem while you insert the tire iron or pry bar at a slight angle clockwise from the sensor body to pry the tire bead up and over the mounting/dismounting head. The tire machine allows you to rotate the tire/wheel assembly counterclockwise while moving the tire bead to the wheel rim's outer edge. Perform the same process for the inner edge of the bead. Remove the tire from the wheel while making sure to clean every interior surface of the tire sealant completely. Start by taking off the tire pressure sensor nut and sensor from the system. Wash off any dirt on the grommet sealing area of the wheel before installing the sensor through its hole with the air border pointing in the opposite direction of the wheel. Selection of new components must be the precise part number and it is unacceptable to apply coatings without authorized specifications because these coatings can impact torque values and operational effectiveness. Set the sensor body at a 90-degree angle against the wheel surface's interior while screwing in the sensor nut until torque reaches 7 N.m (62 lb in). When restating the tire install the mounting/dismounting tool 180 degrees off the valve stem orientation and set the bead transition zone facing 45 degrees counterclockwise to the valve stem location. When moving the tire bead into position on the wheel rim's inside surface, use a clockwise rotation of the tire/wheel assembly and perform the same operation on the outer bead. Position the wheel tire before you proceed with installation. A service replacement tire pressure sensor arrives in OFF state thus requiring a minimum 32 km/h (20 mph) tire/wheel assembly rotation of 10 seconds to activate the internal roll switch. The tire/wheel assembly receives its final placement on the vehicle followed by a vehicle descent before learning the tire pressure sensors takes place.