ChevyParts

My Garage

My Account

Cart

OEM 2010 Chevrolet Silverado 1500 Brake Line

Brake Hose- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

7 Brake Lines found

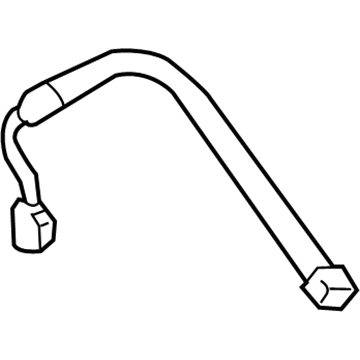

2010 Chevrolet Silverado 1500 Flex Hose, Front Passenger Side Part Number: 84331228

$21.63 MSRP: $40.61You Save: $18.98 (47%)Product Specifications- Other Name: Hose Assembly-Front Brake; Hydraulic Hose; Brake Hose; Brake Line; Hose, Hydraulic Brake

- Position: Front Passenger Side

- Replaces: 15875928, 84183672, 15923784, 22829661, 23245429, 22946996, 25890939

- Item Weight: 1.10 Pounds

- Item Dimensions: 22.2 x 3.0 x 2.5 inches

- Condition: New

- Fitment Type: Direct Replacement

- SKU: 84331228

- Warranty: This genuine part is guaranteed by GM's factory warranty.

2010 Chevrolet Silverado 1500 Brake Line Part Number: 88983905

$68.67 MSRP: $134.44You Save: $65.77 (49%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Pipe, Brake; Hydraulic Hose; Brake Hose; Pipe, Hydraulic Brake Pipe; Pipe, Hydraulic Brake

- Replaces: 25837622, 25837624, 84330459, 22726507, 84380488, 84330461

- Item Weight: 1.10 Pounds

- Item Dimensions: 22.5 x 5.2 x 2.6 inches

- Condition: New

- Fitment Type: Direct Replacement

- SKU: 88983905

- Warranty: This genuine part is guaranteed by GM's factory warranty.

2010 Chevrolet Silverado 1500 Flex Hose, Front Driver Side Part Number: 84331227

$21.20 MSRP: $39.81You Save: $18.61 (47%)Product Specifications- Other Name: Hose Assembly-Front Brake; Hydraulic Hose; Brake Hose; Brake Line; Hose, Hydraulic Brake

- Position: Front Driver Side

- Replaces: 15923783, 22946995, 22829660, 23245428, 25890938, 15875927, 84183671

- Item Weight: 1.10 Pounds

- Item Dimensions: 21.7 x 3.0 x 2.4 inches

- Condition: New

- Fitment Type: Direct Replacement

- SKU: 84331227

- Warranty: This genuine part is guaranteed by GM's factory warranty.

2010 Chevrolet Silverado 1500 Flex Hose Part Number: 25923721

Product Specifications- Other Name: Hose, Hydraulic Brake; Hydraulic Hose; Brake Hose; Brake Line

- Position: Rear

- Item Weight: 1.30 Pounds

- Item Dimensions: 6.1 x 3.1 x 25.8 inches

- Condition: New

- Fitment Type: Direct Replacement

- SKU: 25923721

- Warranty: This genuine part is guaranteed by GM's factory warranty.

2010 Chevrolet Silverado 1500 Flex Hose Part Number: 25923724

Product Specifications- Other Name: Hose, Hydraulic Brake; Hydraulic Hose; Brake Hose; Brake Line

- Position: Rear

- Replaces: 15914428

- Item Weight: 1.30 Pounds

- Item Dimensions: 4.2 x 24.7 x 2.0 inches

- Condition: New

- Fitment Type: Direct Replacement

- SKU: 25923724

- Warranty: This genuine part is guaranteed by GM's factory warranty.

- Product Specifications

- Other Name: Hose, Hydraulic Brake; Hydraulic Hose; Brake Hose; Brake Line

- Position: Driver Side

- Replaces: 15914432

- Item Weight: 0.70 Pounds

- Item Dimensions: 3.1 x 2.1 x 19.8 inches

- Condition: New

- Fitment Type: Direct Replacement

- SKU: 25923717

- Warranty: This genuine part is guaranteed by GM's factory warranty.

- Product Specifications

- Other Name: Hose, Hydraulic Brake; Hydraulic Hose; Brake Hose; Brake Line

- Position: Passenger Side

- Replaces: 15914431

- Item Weight: 0.70 Pounds

- Item Dimensions: 4.1 x 2.1 x 19.2 inches

- Condition: New

- Fitment Type: Direct Replacement

- SKU: 25923716

- Warranty: This genuine part is guaranteed by GM's factory warranty.

2010 Chevrolet Silverado 1500 Brake Line

With a comprehensive array of OEM 2010 Chevrolet Silverado 1500 Brake Line, from fuel pumps to door handles, our website is a one-stop-shop for your needs. All our genuine 2010 Chevrolet Silverado 1500 Brake Line are backed by the manufacturer's warranty and are offered at competitive prices in the market. Rest assured, you can shop with complete confidence.

2010 Chevrolet Silverado 1500 Brake Line Parts Questions & Experts Answers

- Q: How Should Brake Lines Be Replaced to Prevent Brake System Failure on 2010 Chevrolet Silverado 1500?A: Each replacement brake pipe needs steel double-wall tubing for safety and correct placement of original fasteners through proper routing from the right components at original points. A sectioned brake pipe requires the use of fittings and replacement pipes which match the original design specifications and appropriate outside diameter. First examine the repair area before retainer release then pick a sectioning spot which should be somewhere besides bends or mounting points. Before replacement begin by measuring the length of the pipe while making accurate calculations for flare extension: Brake pipe sections require flared ends of 6.35 mm (0.250 in) for 4.76 mm (3/16 in) diameter pipe while 9.50 mm (0.374 in) flares are needed for 6.35 mm (1/4 in) diameter pipe and sections need 12.67 mm (0.499 in) flares for 7.94 mm (5/16 in) diameter pipe. Cut the brake pipe directly to the measured length with the pipe cutter from J 45405 and discard sectioned pieces before choosing suitable brake pipe and tube nuts for installation. Use the coating stripping tool from the J 45405 to remove nylon coating from brake pipe ends without damaging the metal surface before chamfering inside and outside diameters with the de-burring tool in the J 45405. Set up the tubing by installing tube nuts followed by cleaning up all debris from the brake pipe and J 45405 before beginning to flare the pipe by adjusting the die clamping screw and placing the die halves inside the die cage. The end of prepared pipe should be inserted into dies which are secured with clamping screws before using forming mandrel and finishing cone to form the flare. Check the flare diameter after die removal: The dimensions of the formed pipe flares measure between 6.74-7.10 mm (0.265-0.279 in) for 4.76 mm (3/16 in) pipe and 8.57-9.27 mm (0.344-0.358 in) for 6.35 mm (1/4 in) pipe and 10.42-10.79 mm (0.410-0.425 in) for 7.94 mm (5/16 in) pipe. Follow these steps to use brackets on new pipes: first use a brake pipe bending tool to form them then position components with an 19 mm (3/4 in) gap and install appropriate unions followed by retaining the pipes and completing the hydraulic brake system bleed then test for leaks during engine start and assisted brake application.