ChevyParts

My Garage

My Account

Cart

OEM Buick Century Brake Drum

- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

2 Brake Drums found

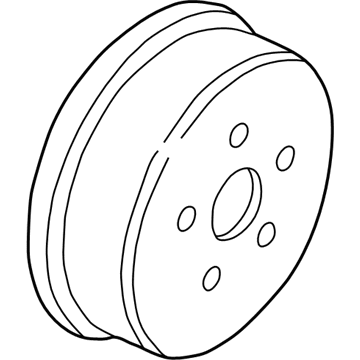

Buick Century Brake Drum Part Number: 88957254

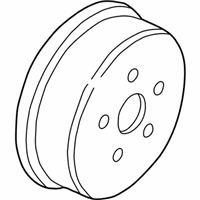

Buick Century Brake Drum, Rear Part Number: 18021269

Buick Century Brake Drum

Want to cut long-term maintenance and repair costs? Choose OEM Brake Drum. Those parts deliver top durability you can trust. On our site, you'll find a huge catalog of genuine Buick Century parts. Prices are unbeatable, so you can keep more in your pocket. Every OEM Buick Century Brake Drum includes a manufacturer's warranty. You can also get an easy return policy that keeps buying risk free. Fast delivery, get your car on the road quickly. It's simple to search, compare, and order. Stop guessing about quality or fit. Order today and save with parts that last.

The Brake Drum in Buick Century engaged in the braking system and its main role is to decelerate the car through friction. This is done through the rubbing of the brake shoes on the inner face of the drum which is ordinarily made of special cast iron that is notorious for its qualities of sturdiness and high heat conductivity. Since the brake drum also rotates with the wheel and the axle, pressing the brakes makes the brake lining to push outward with a force in a radial movement that creates the necessary friction to slow the car. Although the overview does not point out different types or styles of the brake drum in the Buick Century car models, the basic principle is the same across all the models, and stress is laid on the heat dissipation since there is usually friction when the brakes are applied.

Buick Century Brake Drum Parts and Q&A

- Q: How should brake drums be serviced and repaired on Buick Century?A:Start Brake Drum work by cleaning the part while searching for cracks, scoring, severe groove marks, out-of-round shape, and taper. Normal light markings on the surface of a drum should not reach more than 0.51 mm (0.020 inch) in depth and will not impact the brake system. The presence of cracks in a drum requires replacement since welding the part creates safety hazards. All minor Brake Drum marks should be flattened by hand while extensive surface grooves need refacing during brake lining replacement to avoid unnecessary component wear. Brake Shoe adjustment may become imprecise while severe tread damage and a wobbling Brake Pedal result when the drum shows out-of-round or taper conditions. Take out-of-round and taper wear measurements at different right angles by placing the j22364-01 or a micrometer tool at the drum's open and closed edges with proper extension rods. Normal drum refinish ends when the metal reveals true and smooth surfaces. Replace the drum when you cannot reach the specified rebore diameter during cleaning. The maximum diameter stamp on brake drums shows the highest amount of wear but remains an unrefinishable size. Use sharp tools fitted with vibration dampers to reduce the drum dimension by no more than 0.76 mm (0.030 inch) before its discard diameter. To achieve excellent results when refinishing choose 200 rpm for the Spindle speed plus adjust the rough cutting cross feed from 0.25 to 0.15 mm (0.010 to 0.006-inch) each revolution and stem from making finish cuts deeper than 0.05 mm (0.002 inch) per revolution. Run the lathe while smoothing the surface after cutting by sanding the surface with 80 to 120 grit emery cloth. Check drum condition when wheel balancing becomes hard especially after refurbishment. Reinstall all balancing weights as given by the manufacturer.