ChevyParts

My Garage

My Account

Cart

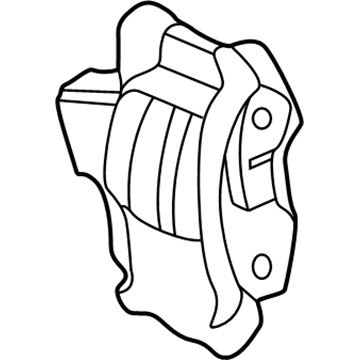

OEM Buick Century Brake Calipers

Caliper- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

17 Brake Calipers found

Buick Century Caliper Part Number: 18017231

$53.78 MSRP: $98.14You Save: $44.36 (46%)Ships in 1-3 Business DaysBuick Century Caliper Part Number: 18015755

$53.60 MSRP: $97.81You Save: $44.21 (46%)Ships in 1-3 Business DaysBuick Century Caliper Part Number: 88965667

$76.17 MSRP: $231.41You Save: $155.24 (68%)Buick Century Caliper Part Number: 88965666

$70.96 MSRP: $215.56You Save: $144.60 (68%)Buick Century Caliper, Front Passenger Side Part Number: 19141029

$53.78 MSRP: $98.14You Save: $44.36 (46%)Ships in 1-3 Business DaysBuick Century Caliper, Front Driver Side Part Number: 19141028

$53.78 MSRP: $98.14You Save: $44.36 (46%)Ships in 1-3 Business DaysBuick Century Caliper, Front Part Number: 19140969

$46.08 MSRP: $84.05You Save: $37.97 (46%)Ships in 1-3 Business DaysBuick Century Caliper, Front Part Number: 19140968

$46.08 MSRP: $84.02You Save: $37.94 (46%)Ships in 1-3 Business DaysBuick Century Caliper, Front Passenger Side Part Number: 19140953

$53.60 MSRP: $97.81You Save: $44.21 (46%)Ships in 1-3 Business DaysBuick Century Caliper Overhaul Kit, Rear Part Number: 18023387

Buick Century Overhaul Kit, Front Part Number: 18003724

Buick Century Caliper, Driver Side Part Number: 3487476

Buick Century Caliper Part Number: 18014439

Buick Century Caliper, Front Passenger Side Part Number: 18046201

Buick Century Caliper, Front Driver Side Part Number: 18046200

Buick Century Overhaul Kit, Front Part Number: 18017156

Buick Century Caliper, Driver Side Part Number: 18013998

Buick Century Brake Calipers

Want to cut long-term maintenance and repair costs? Choose OEM Brake Calipers. Those parts deliver top durability you can trust. On our site, you'll find a huge catalog of genuine Buick Century parts. Prices are unbeatable, so you can keep more in your pocket. Every OEM Buick Century Brake Calipers includes a manufacturer's warranty. You can also get an easy return policy that keeps buying risk free. Fast delivery, get your car on the road quickly. It's simple to search, compare, and order. Stop guessing about quality or fit. Order today and save with parts that last.

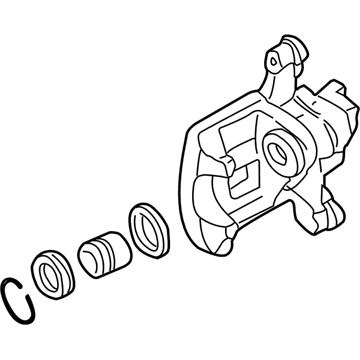

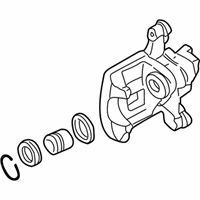

The Brake Caliperss found in Buick Century is an imperative component in the stopping system as it translates hydraulic pressure from the master cylinder to mechanical so as to clasp the brake pad against the rotor and thus slowing down or halting the car. Buick Century models utilize two primary types of brake calipers: These two are; fixed and floating. There are several designs of calipers: fixed ones which have more than one piston on either side of the rotor, giving more contact pressure and higher operating performance; and floating ones which has only one piston on one side only and this slides in to apply the pressure and as such are comparatively more simple but also slightly more liable to get stuck and wear unevenly. In the past, the Buick Century brake calipers have been made from cast iron for the body, and steel or phenolic for the pistons. There it becomes possible to obtain performance options in terms of brake calipers which offer better, more appealing results than the original equipment counterparts. In addition, proper inspection and maintenance will help to avoid such problems as leaks or uneven pad wear due to such imperfections as non- uniformity of calipers.

Buick Century Brake Calipers Parts and Q&A

- Q: How to replace the front brake calipers on Buick Century?A:Check the fluid level in the brake master cylinder reservoir as your first step before front brake caliper replacement. The fluid level must be adjusted so it stays at the midway point between maximum and minimum while inspecting the reservoir. Begin by elevating the vehicle position and then remove both front tire and wheel parts from their mounting position. A large c-clamp should be used to press the caliper piston into the caliper bore while it rests against the back of the outboard brake pad until the caliper can slide off the rotor. Install a c-clamp with hand-tightened 2 wheel lug nuts holding the rotor against the hub. First remove the c-clamp before removing the brake hose-to-caliper bolt and throwing away the two copper brake hose gaskets. Seal the opening of the front brake hose with a piece of material to stop excessive fluid escapes. Remember to note the positioning of caliper pin bolts because a bushed leading caliper pin bolt exists alongside a solid trailing caliper pin bolt. First remove the caliper pin bolts followed by taking out the caliper component from the rotor and caliper bracket. Check the caliper bolt boots for damage then replace damaged ones and examine the caliper bolts for corrosion ordamage before installing new caliper pin bolts when needed. When reusing brake caliper pin bolts for installation clean them with a shop cloth and apply delphi p/n 18046532 or equivalent lubricant as long as no excess lubricant accumulates at the end of the leading caliper pin. Position the caliper over the rotor before placing it onto the caliper bracket and fasten the caliper pins by securing the boots into their groove; tighten the bolts to a torque of 95 nm which equals to 70 ft. Lbs. Install the brake hose bolt that is assembled with new copper brake hose gaskets to the brake hose and tighten the brake hose-to-caliper bolt to 54 nm (40 ft. Lbs.). Lower the vehicle after installing the front tire and wheel assembly and filling the master cylinder to the correct brake fluid level before bleeding the brake system while checking for fluid leaks.

- Q: How to service and repair the front brake calipers on Buick Century?A:To service and repair the front brake caliper, first remove the caliper. Be careful not to put fingers in the way of the calipers pistons(s) when applying compressed air as the piston(s) will be fired out causing harm to the user. Pad the interior of the caliper housing using clean cloths during piston removal, using a minimal amount of air to help remove pistons from the bores to avoid damaging them. Blow compressed air through the caliper inlet hole; it will exit through the piston boot, removing the piston. Examine the piston for scoring, nicks, corrosion or worn chrome plating, and replace if the problems are present. Gently remove the caliper boot also in order not to scratch the housing bore without using plastic wood and seal removal tool. Check the caliper bore and seal grooves for scoring, nicks, corrosion or wear, polishing the slight corrosion using a crocus cloth. The disadvantage of the rolling bearing brake system is the inability of the brake pads to come into contact with the rotor on this type of braking (Ripa, NileCrimea, Semerena et al., par. 42). Hence, washers should be applied to the brake pads to maintain friction between the pads and the rotor (Ripa, NileCrimea, Semerena et al., par. 41). As it is inherently impossible to clean the surface, take into account the condition of the housings of the-pad nests for the mechanic in stainings brake installing (Ripa, NileCrimea, Semerena et Inspect the bolt boots for cuts, tears, or wear, changing out any ridden boots . Check the caliper bolts and if they are corroded, do not try to make them look good by polishing, but instead, replace them. Inspect the seal groove in the caliper bore for nicks or burr and replace the caliper if groove is damaged. Remove the bleeder valve cap and bleeder valve from the caliper housing and then clean out all parts in the denatured alcohol and dry out them using filtered, non-lubricated compressed air. Brake caliper compressed air bleeder valve; blow out all passages within the housing to caliper, and to the bleeder valve with filtered, non-lubricated compressed air. For assembly, the two tools Instrument J36349 Front Dust Boot Seal Installer are used to install the bleeder valve and cap on the caliper housing by tightening the bleeder valve to13 Nm (115 inch lbs). Replace a new lubricated piston seal into the caliper bore grooves, making sure that it is not twisted, and install the lubricated boot on the piston and lubricate the piston with cleaned brake fluid. Insert the piston and boot into the caliper bore, forcing the piston to the bottom, and seat the caliper boot in the caliper housing counterbore with the help of the tool, j36349 finally installing the caliper.