ChevyParts

My Garage

My Account

Cart

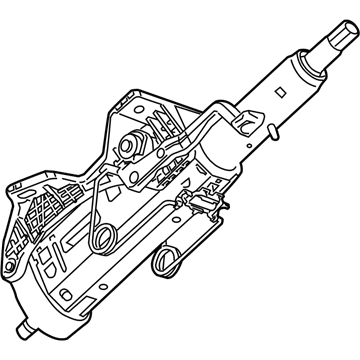

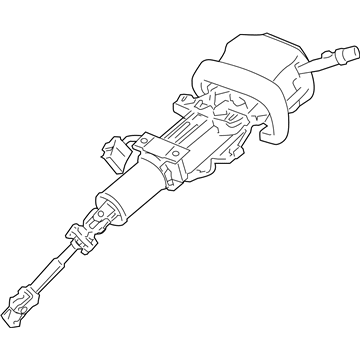

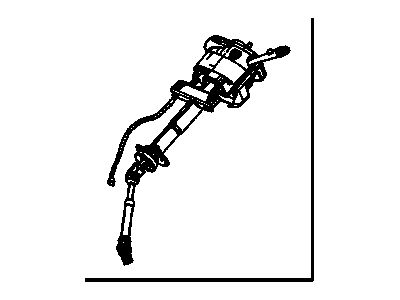

OEM Buick LaCrosse Steering Column

Steering Column Tilt- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

46 Steering Columns found

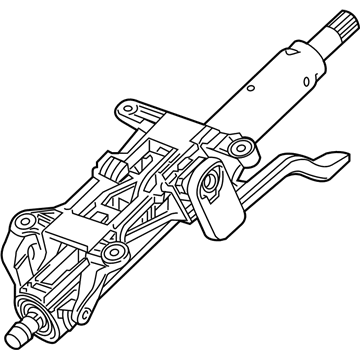

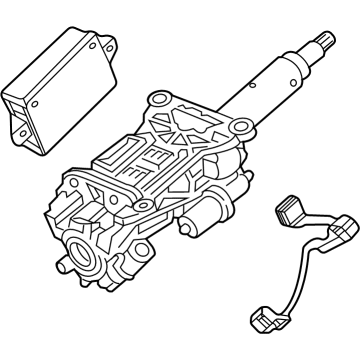

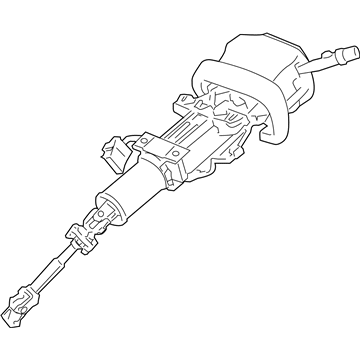

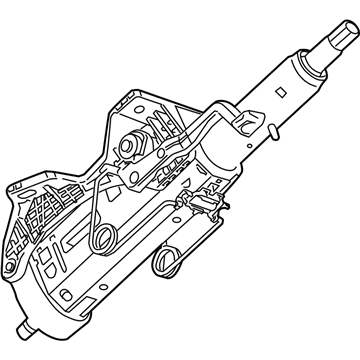

Buick LaCrosse Steering Column Part Number: 84192523

$107.12 MSRP: $167.79You Save: $60.67 (37%)Ships in 1-3 Business DaysBuick LaCrosse Steering Column Part Number: 84218849

$447.84 MSRP: $707.68You Save: $259.84 (37%)Ships in 1-3 Business DaysBuick LaCrosse Steering Column, Black Part Number: 39008866

$134.97 MSRP: $212.37You Save: $77.40 (37%)Buick LaCrosse Steering Column, Gray Part Number: 15247328

Buick LaCrosse Steering Column Part Number: 15247334

Buick LaCrosse Steering Column, Gray Part Number: 15247339

Buick LaCrosse Steering Column, Black Part Number: 23365711

Buick LaCrosse Steering Column Part Number: 25999448

Buick LaCrosse Steering Column Part Number: 25999449

Buick LaCrosse Steering Column Part Number: 25999454

Buick LaCrosse Steering Column Part Number: 25999433

Buick LaCrosse Steering Column Part Number: 25999431

Buick LaCrosse Steering Column Part Number: 25999455

Buick LaCrosse Steering Column, Titanium Part Number: 25999429

Buick LaCrosse Steering Column Part Number: 25999430

Buick LaCrosse Steering Column Part Number: 15247327

Buick LaCrosse Steering Column, Gray Part Number: 15247326

Buick LaCrosse Steering Column Part Number: 15247340

Buick LaCrosse Steering Column, Titanium Part Number: 25999434

Buick LaCrosse Steering Column Part Number: 25999445

| Page 1 of 3 |Next >

1-20 of 46 Results

Buick LaCrosse Steering Column

Want to cut long-term maintenance and repair costs? Choose OEM Steering Column. Those parts deliver top durability you can trust. On our site, you'll find a huge catalog of genuine Buick LaCrosse parts. Prices are unbeatable, so you can keep more in your pocket. Every OEM Buick LaCrosse Steering Column includes a manufacturer's warranty. You can also get an easy return policy that keeps buying risk free. Fast delivery, get your car on the road quickly. It's simple to search, compare, and order. Stop guessing about quality or fit. Order today and save with parts that last.

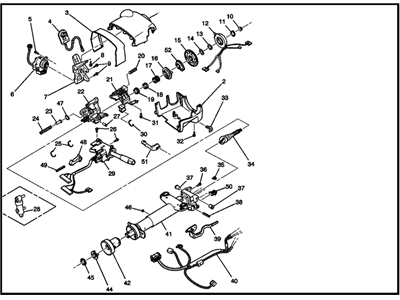

Buick LaCrosse Steering Column Parts and Q&A

- Q: What should be inspected on those involved in accidents that may have a damaged or misaligned steering column on Buick LaCrosse?A:The Steering Column in vehicles becomes damaged or misaligned whenever an accident occurs and leads to frame damage or major body damage or sheet metal damage or impact to the Steering Column or deployment of the supplemental inflatable restraints system. Check each capsule installed on the Steering Column bracket assembly to confirm its proper placement within bracket slots and inspect general looseness by manually pushing and pulling the components. The repair procedure must get into action under these circumstances: when the bracket connects to a bolted jacket assembly and capsule seats are missing securement yet when bracket welding occurs to a jacket assembly and capsule installation does not meet specification. The measurement between the lower edge of the upper jacket and the specified point on the lower jacket serves to detect jacket assembly collapse. When measurement results fall outside of stated specifications, replace the entire jacket assembly. A visual check of the Steering Shaft should be performed for sheared injected plastic. A replacement Steering Shaft must be installed if sheared plastic is detected. A dial indicator must be used to measure the runout of the Steering Shaft at the lower end while rotating the wheel during inspection. This check verifies that runout stays below 1.60 mm (0.06 in).