ChevyParts

My Garage

My Account

Cart

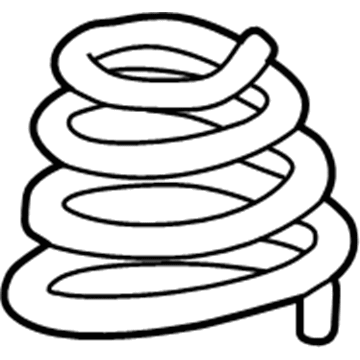

OEM Buick Regal Coil Springs

Strut Spring- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

20 Coil Springs found

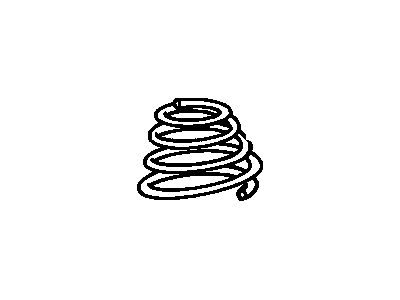

Buick Regal Coil Spring, Rear Part Number: 13276195

$59.85 MSRP: $116.16You Save: $56.31 (49%)

Buick Regal Coil Spring, Rear Part Number: 13312083

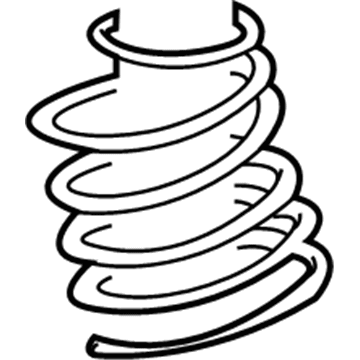

$59.85 MSRP: $116.16You Save: $56.31 (49%)Buick Regal Coil Spring, Front Part Number: 20901079

$124.31 MSRP: $222.98You Save: $98.67 (45%)Ships in 1-3 Business DaysBuick Regal Coil Spring, Rear Part Number: 22910897

$59.86 MSRP: $106.91You Save: $47.05 (45%)Ships in 1-3 Business DaysBuick Regal Coil Spring, Front Part Number: 22788524

$67.95 MSRP: $137.94You Save: $69.99 (51%)Ships in 1-2 Business Days

Buick Regal Coil Spring, Front Part Number: 22133030

$95.19 MSRP: $169.98You Save: $74.79 (44%)Buick Regal Spring, Front Part Number: 14029388

Buick Regal Coil Spring, Rear Part Number: 23144010

Buick Regal Spring, Front Part Number: 14100165

Buick Regal Coil Spring, Front Part Number: 22788523

Buick Regal Coil Spring, Rear Passenger Side Part Number: 10415609

Buick Regal Coil Spring, Front Part Number: 22863829

Buick Regal Coil Spring, Rear Part Number: 22885343

Buick Regal Coil Spring, Front Part Number: 23125732

Buick Regal Coil Spring, Front Part Number: 14100175

Buick Regal Auxiliary Spring, Rear Part Number: 10130162

Buick Regal Coil Spring, Front Part Number: 22133006

Buick Regal Coil Spring, Rear Part Number: 23144009

$46.51 MSRP: $83.06You Save: $36.55 (44%)Buick Regal Coil Spring, Front Part Number: 13260261

Buick Regal Coil Spring, Front Part Number: 22744711

$44.74 MSRP: $79.89You Save: $35.15 (44%)

Buick Regal Coil Springs

Want to cut long-term maintenance and repair costs? Choose OEM Coil Springs. Those parts deliver top durability you can trust. On our site, you'll find a huge catalog of genuine Buick Regal parts. Prices are unbeatable, so you can keep more in your pocket. Every OEM Buick Regal Coil Springs includes a manufacturer's warranty. You can also get an easy return policy that keeps buying risk free. Fast delivery, get your car on the road quickly. It's simple to search, compare, and order. Stop guessing about quality or fit. Order today and save with parts that last.

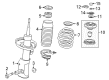

Suspension of Buick Regal involves the use of special parts known as coil springs and these can be well described as being fundamental to the support and suspension systems of the Buick Regal vehicles. These coil springs aid in the provision of correct chassis height so that wheels are appropriately aligned or parallel and learners from such concerns like scrapping of tires as well as sinking into the car base. Different types of coil springs have been used in the successive models of Buick Regal such as linear rate springs, progressive springs and dual rate springs where the stiffness is varied to improve the characteristic of handling and comfort of the car. Linear rate springs offer a constant value of resistance throughout the cycle while the progressive springs have coils which change or gradually reduce the rate of compression thus provide the comfort to ride and they perform excellent during dynamic modes. There are distinguished dual rate springs that allow using two different rates of the spring altogether. Further, Buick Regal owners can also go for the Power Adjustable Coil Springs which usually has feature of Tuneable Height Control where regal owners can also enjoy the adjustability of the ride heights in according to wheel and tire changes. In general, the coil springs of the Buick Regal cars are keeping an essential balance and comfort level while driving the vehicles.

Buick Regal Coil Springs Parts and Q&A

- Q: What Tools Are Required to Service and Repair Front Coil Springs and Shock Absorber on Buick Regal?A:The following tools are needed to service and repair the suspension strut: holding fixture (J 3289-20), strut compressor (J 34013-B), damper rod clamp (J 34013-20), alignment rod (J 34013-197), strut rod nut socket (J 42991), strut compressor lower adapter (J 34013-971), and strut compressor upper adapter (J 34013-972) are other parts. Start by stripping off the strut from the vehicle and fitting it into the strut compressor (J 34013-B), fitting the strut compressor lower adapter (J 34013-971), strut compressor upper adapter (J 34013-972), and holding fixture (J 3289-20). Turn the compressor forcing screw until the spring is slightly compressed, and then use a 45 torx socket to hold the strut shaft and remove the strut mount nut with the strut rod nut socket (J 42991). Replace the alignment rod (J 34013-197) to direct the strut shaft in the upper mount while loosening compressor screw and pulling the strut shaft out. For assembly, properly orienting the strut mount and assembling the strut in the strut compressor (J 34013-B) with adapters and the damper rod clamp (J 34013-20). Inset the spring and push it up, replace the upper locking pin. Using the alignment rod (J 34013-197), use to guide the strut shaft turn the compressor screw clockwise until strut shaft threads are visible. The washer and nut applied, damper rod clamp (J 34013-20) removed; tighten strut mount nut to 85 nm (63 ft. Lbs.) with the strut rod nut socket (J 42991) while braking the strut shaft with a 45 torx socket. Lastly, take out the strut from the compressor and place it back into the vehicle.