ChevyParts

My Garage

My Account

Cart

OEM Chevrolet Avalanche 1500 Fuel Pressure Regulator

Fuel Tank Pressure Regulator- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

6 Fuel Pressure Regulators found

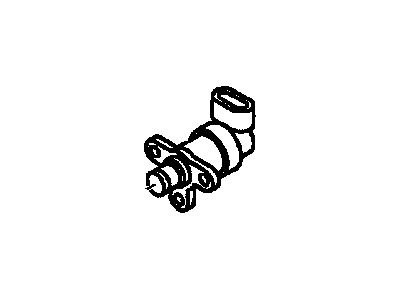

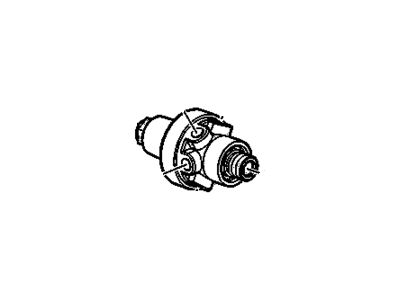

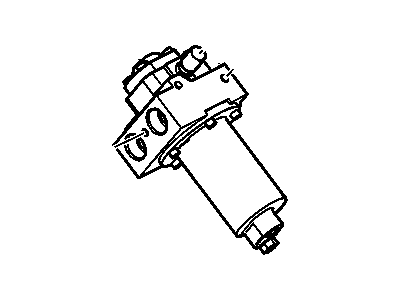

Chevrolet Avalanche 1500 Fuel Pressure Regulator Part Number: 97728979

$368.14 MSRP: $579.25You Save: $211.11 (37%)

Chevrolet Avalanche 1500 Fuel Pressure Regulator Part Number: 19245530

$92.92 MSRP: $188.72You Save: $95.80 (51%)Ships in 1-3 Business DaysChevrolet Avalanche 1500 Fuel Pressure Regulator Part Number: 19210686

$77.57 MSRP: $157.56You Save: $79.99 (51%)Ships in 1-2 Business DaysChevrolet Avalanche 1500 Fuel Pressure Regulator Part Number: 52373074

Chevrolet Avalanche 1500 Fuel Pressure Regulator Part Number: 52372836

Chevrolet Avalanche 1500 Fuel Pressure Regulator Part Number: 52372245

Chevrolet Avalanche 1500 Fuel Pressure Regulator

Want to cut long-term maintenance and repair costs? Choose OEM Fuel Pressure Regulator. Those parts deliver top durability you can trust. On our site, you'll find a huge catalog of genuine Chevrolet Avalanche 1500 parts. Prices are unbeatable, so you can keep more in your pocket. Every OEM Chevrolet Avalanche 1500 Fuel Pressure Regulator includes a manufacturer's warranty. You can also get an easy return policy that keeps buying risk free. Fast delivery, get your car on the road quickly. It's simple to search, compare, and order. Stop guessing about quality or fit. Order today and save with parts that last.

Chevrolet Avalanche 1500 Fuel Pressure Regulator Parts and Q&A

- Q: What are the critical steps involved in servicing a fuel pressure regulator on Chevrolet Avalanche 1500?A:The Fuel Pressure Regulator service requires precise execution because the system contains three distinct regulator types and Fuel Rail designs which have distinctive receiving ports and particular retaining clips that cannot be exchanged. Start the procedure by eliminating pressure from the fuel system before dealing with the Fuel Pressure Regulator vacuum hose and thoroughly cleaning the retainer surrounding area. You must pull out both the Fuel Pressure Regulator retainer and the Fuel Pressure Regulator from the Fuel Rail while verifying that the back up ring and regulator seal o-ring together with the regulator filter and regulator seal o-ring remain outside of the Fuel Rail. Inspection of the new Fuel Pressure Regulator retainer should verify its correct identification because the tabs should only fit on the straight vacuum port retainer and the e85-straight vacuum port retainer but not the angle vacuum port retainer . The Fuel Pressure Regulator requires installation of back up ring and regulator seal o-ring followed by a regulator filter and another regulator seal o-ring. Before this installation, apply clean engine oil to o-rings (11, 13). It is crucial to install fresh o-rings together with a new retaining clip when reinstalling the component. Secure the new retainer for the Fuel Pressure Regulator and restore both the Fuel Pressure Regulator vacuum hose and reinstall the fuel fill cap with negative Battery Cable connection. A leak check requires activating the ignition while leaving the engine off for two seconds before switching it off for ten seconds and repeating the procedure with the ignition on and engine off for leak inspection.