ChevyParts

My Garage

My Account

Cart

OEM Chevrolet Cobalt Fuel Pressure Sensor

Fuel Tank Pressure Sensor- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

2 Fuel Pressure Sensors found

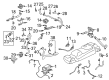

Chevrolet Cobalt Fuel Pressure Regulator, Passenger Side Part Number: 16238399

$54.17 MSRP: $101.06You Save: $46.89 (47%)

Chevrolet Cobalt Pressure Sensor, Passenger Side Part Number: 13502903

$48.74 MSRP: $100.17You Save: $51.43 (52%)Ships in 1-2 Business Days

Chevrolet Cobalt Fuel Pressure Sensor

Want to cut long-term maintenance and repair costs? Choose OEM Fuel Pressure Sensor. Those parts deliver top durability you can trust. On our site, you'll find a huge catalog of genuine Chevrolet Cobalt parts. Prices are unbeatable, so you can keep more in your pocket. Every OEM Chevrolet Cobalt Fuel Pressure Sensor includes a manufacturer's warranty. You can also get an easy return policy that keeps buying risk free. Fast delivery, get your car on the road quickly. It's simple to search, compare, and order. Stop guessing about quality or fit. Order today and save with parts that last.

Chevrolet Cobalt Fuel Pressure Sensor Parts Questions & Experts Answers

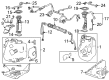

- Q: How to replace the fuel injection fuel rail fuel pressure sensor on Chevrolet Cobalt?A:The procedure to change the fuel injection Fuel Rail Fuel Pressure Sensor starts by using an appropriate method to pat the high side fuel system pressure. The first step includes disconnecting the fuel injector wiring harness electrical connector from the fuel injection Fuel Rail Fuel Pressure Sensor but avoiding any movements of the foam insulator to prevent damage. Use a 27 mm socket inserted through the foam insulator access point to grasp the fuel injection Fuel Rail Fuel Pressure Sensor but apply pressure only on the hexagonal mount to protect the sensor. Install a shop towel under the sensor position before you pull out and dispose of the exhausted sensor to allow fuel to drain. Inspection of the Fuel Rail sealing cone requires drying it first before checking for any residue or dirt. Apply silicon-free engine oil gm p/n 12345610 (Canadian P/N 993193) equivalent to lubricate the threads and sealing cone of the Fuel Rail as well as the new fuel injection Fuel Rail Fuel Pressure Sensor. Before final tightening to 33 nm (25 lb ft), hand tighten the new sensor then remove it followed by a lubrication procedure of reinstallation. After installing the new high-pressure fuel line the technician should connect the fuel injector wiring harness electrical connector and place the new low side fuel pressure service port cap. Check for fuel leaks by first placing a paper towel between the sensor and generator then start the vehicle for five minutes before cessation to evaluate the towel for fluid presence. Repetition of this series of steps is needed when wetting is identified.