ChevyParts

My Garage

My Account

Cart

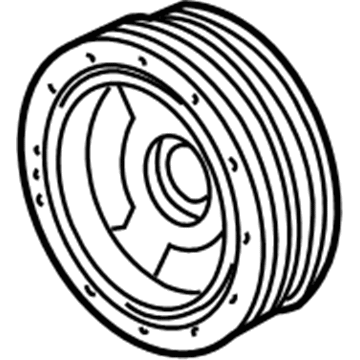

OEM Chevrolet Express 1500 Harmonic Balancer

Engine Harmonic Balancer- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

6 Harmonic Balancers found

Chevrolet Express 1500 Vibration Damper Part Number: 19300488

$115.88 MSRP: $199.00You Save: $83.12 (42%)Ships in 1-2 Business Days

Chevrolet Express 1500 Vibration Damper Part Number: 10243271

$91.05 MSRP: $156.37You Save: $65.32 (42%)Ships in 1-2 Business Days

Chevrolet Express 1500 Vibration Damper Part Number: 10224885

$65.09 MSRP: $106.52You Save: $41.43 (39%)Chevrolet Express 1500 Vibration Damper Part Number: 19417972

$409.58 MSRP: $650.30You Save: $240.72 (38%)Ships in 1-2 Business DaysChevrolet Express 1500 Vibration Damper Part Number: 10243272

$207.93 MSRP: $357.10You Save: $149.17 (42%)Ships in 1-2 Business Days

Chevrolet Express 1500 Vibration Damper Part Number: 12634105

Chevrolet Express 1500 Harmonic Balancer

Want to cut long-term maintenance and repair costs? Choose OEM Harmonic Balancer. Those parts deliver top durability you can trust. On our site, you'll find a huge catalog of genuine Chevrolet Express 1500 parts. Prices are unbeatable, so you can keep more in your pocket. Every OEM Chevrolet Express 1500 Harmonic Balancer includes a manufacturer's warranty. You can also get an easy return policy that keeps buying risk free. Fast delivery, get your car on the road quickly. It's simple to search, compare, and order. Stop guessing about quality or fit. Order today and save with parts that last.

Chevrolet Express 1500 Harmonic Balancer Parts and Q&A

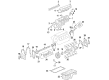

- Q: How to replace the harmonic balancer on Chevrolet Express 1500?A:The replacement of the crankshaft balancer requires several tools: j45059 angle meter combined with j41816 crankshaft balancer remover and j41816-2 crankshaft end protector as well as j42386-a Flywheel holding tool and j41665 crankshaft balancer and sprocket installer. Start the operation by disintegrating the air conditioning Drive Belt in equipped vehicles or the accessory Drive Belt if not present. Proceed by taking out the lower Fan Shroud and the Starter motor from the vehicle. Verify that j42386-a fits properly with the engine Flywheel teeth. Fit the j42386-a onto the Flywheel while using one m10-1.5 x 120 mm hot and one m10-1.5 x 45 mm bolt which needs to be tightened to 50 nm (37 ft. Lbs.). Safeguard the crankshaft balancer bolt because it needs to be used later during assembly. Use the j41816 together with j41816-2 to uninstall and clean the crankshaft balancer before inspection. Install the crankshaft balancer directly onto the crankshaft before using the j41665 tool to accomplish the installation. Together with the installer use the threaded rod, nut, and washer to rotate the nut clockwise for starting the balancer onto the crankshaft. The installation process requires reversing the tool while tightening the balancer until it reaches complete installation. The used crankshaft balancer bolt requires installation after which it needs to be tightened to 330 nm (240 ft. Lbs.). Use the j41665 until the balancer is correctly set; if incorrect installation persists, perform the procedure once more with the j41665. Installation of a new crankshaft balancer bolt requires initial torque to 50 nm (37 ft. Lbs.) followed by its timing to 140 degrees using the j45059. To finish the procedure reinstall the Starter motor along with the lower Fan Shroud then put on the accessory Drive Belt (when excluding A/C) followed by the a/c Drive Belt on vehicles with this equipment. Finish by running the crankshaft position system variation learn procedure.