ChevyParts

My Garage

My Account

Cart

OEM Chevrolet K3500 Distributor

Ignition Distributor- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

2 Distributors found

Chevrolet K3500 Distributor Assembly Part Number: 19179576

$304.49 MSRP: $554.62You Save: $250.13 (46%)Ships in 1-2 Business DaysChevrolet K3500 Distributor Assembly Part Number: 94672691

$383.36 MSRP: $775.86You Save: $392.50 (51%)Ships in 1-2 Business Days

Chevrolet K3500 Distributor

Want to cut long-term maintenance and repair costs? Choose OEM Distributor. Those parts deliver top durability you can trust. On our site, you'll find a huge catalog of genuine Chevrolet K3500 parts. Prices are unbeatable, so you can keep more in your pocket. Every OEM Chevrolet K3500 Distributor includes a manufacturer's warranty. You can also get an easy return policy that keeps buying risk free. Fast delivery, get your car on the road quickly. It's simple to search, compare, and order. Stop guessing about quality or fit. Order today and save with parts that last.

The Chevrolet K3500 Distributor can be considered as an important part that boosts the performance and reliability of Chevrolet's K3500 ranging from 1988 to 2002. This Distributor effectively connects high voltage current from the ignition coil to spark plugs, sequentially in the right manner and timely for prime performance of the engine. In each year, the equipments of the Chevrolet K3500 have been changing from the mechanical kinds of distributors to electronic kinds of distributors with Hall Effect sensors that do not call for the wear component such as breaker points and hence it assures reliability and less in magnitude of maintainances. Chevrolet K3500 Distributor is designed to fit different models of K3500 which makes it convenient for the owners who seem to preserve the performances of the vehicle and its safety. On the part of the combustion system, it helps to enhance the ignition timing that can be regarded as a way to enhance fuel economy and to minimize emissions in compliance with modern auto industry trends. However, for light trucks, the Chevrolet K3500 Distributor has a distinct advantage over other automobiles in the market concerning its build and flexibility, this goes to show that Chevrolet automobiles are built to a high standard. Here, we have features as the dual points or the electronic ignition options that not only improve the performance of this Distributor but make sure that the K3500 can deal with the difficult work as the easiest task of its kind. In conclusion, the Chevrolet K3500 Distributor describes the synthesis of the reliable, high performance, and advances features of the Chevrolet K3500 that has established it has a good reputation in the global automobile market.

Chevrolet K3500 Distributor Parts and Q&A

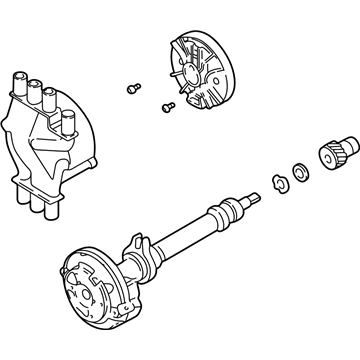

- Q: How to service and repair the distributor on Chevrolet K3500?A:To service and repair the Distributor, carefully disassemble it, labeling the Distributor driven gear, Distributor shaft, rotor holes for correct reassembly, as incorrect alignment causes a no-start condition and engine damage. Remove two screws fixing the Distributor Cap to the housing and throw them away, and then remove the cap off. Line up the white paint mark in the bottom of the stem of the Distributor with the pre-drilled indent hole at the bottom of the gear. Position the rotor segment appropriately for v6 engine or v8 engine ; if not, replace the Distributor. Next, take out the two screws holding the rotor in place, take out the rotor, and remember the locating holes. Loosen the two screws that are keeping the camshaft position (CMP) sensor and dispose off these screws, position the square-cut opening of the vane wheel facing the cmp sensor before pulling out the sensor. Note the dimple under the roll pin hole on one side of the gear for the orientation at reassembly. Support the Distributor drive gear in a v block and drive the roll pin from the point using a suitable punch and removing the driven gear off the Distributor shaft taking the round washer and tang washer with it and the round washer if included for the 7.4l engine. Remove the old oil seal. For assembly align the square-cut hole in the vane wheel for the cmp sensor and place the sensor in the housing, then apply 2 new screws and tighten them to 2.2n.m (20 lb in). Locate the correct rotor mounting at rotor screw holes & rotor locator pin holes and then install the Distributor rotor with reference to the index marks and tighten the rotor hold down screws to 1.9 n.m (17 lb in). If necessary, put the round washer into place for the 7.4l engine, then the tang washer over the bottom the Distributor shaft and the round washer. Mount the driven gear by index marks in line with the rotor along the marks for a v6 or v8 production, having the white paint off the bottom stem of Distributor mark lining up with pre-drilled indent hole on the bottom of the gear. If the driven gear is improperly installed, the dimple will be around 180 degrees from the rotor segment. Rep the expound to a distributary bobble gear in a v-nose and accept the tonnret pin by using a rightful punch and hammer to affix the driven cusp. Lastly, install the Distributor Cap to the two new screws that need to be tightened to 2.4 n.m (21 lb in) and the new oil seal at the mounting flange of the Distributor base.

- Q: How to replace the distributor on Chevrolet K3500?A:To change the Distributor, first, turn the Ignition Switch off and take the air cleaner assembly and Ignition Coil apart. Remove the Spark Plug Wires from the Distributor Cap by twisting each wire 1/2 turn and pulling only on the boot. Disconnect the electrical connector from the Distributor base and screw the two holding the cap of the Distributor to the housing and remove them, discarding the screws as well. Take a grease pencil in noting down the place of rotor in relation that of the Distributor housing and mark both the Intake Manifold and the Distributor housing. Remove the mounting clamp hold down bolt, and the Distributor while noting that the rotor moves counter-clockwise over 42 degrees during removal. Considering installation procedure 1, in case it is new Distributor assembly, it is necessary to mark a new housing in the same points as it is necessary for the original, align a rotor with the second mark, move a Distributor into the engine, and make sure the hold-down base is in accordance with the Intake Manifold. Upon installing the Distributor the rotor should rotate to the left clockwise approximately about 42 degrees and when seated the rotor segment should line up to the first mark. In case of misalignment, distribute it and reinstall. Tighten the Distributor clamp bolt to 25 n.m (18 lb ft) and put the Distributor Cap with two new screws to 2.4 n.m (21 lb in), reconnect the electrical connector, and replace the Spark Plug Wires along with the Ignition Coil and attach the air cleaner assembly. Use a scan tool in order to gauge the camshaft retard offset value. For installation procedure 2, turn the number 1 cylinder to top dead center (TDC) of the compression stroke, align white paint mark, on the bottom heel of the lower stem of the Distributor with the pre-drilled indent hole in the gear, and mark thectype Distributor correctly. Lining the oil pump drive shaft with a long screwdriver, guide the Distributor into the engine, with the spark plug towers to be perpendicular with the rotor segment alignment to the pointer on the Distributor base. If misalignment is encountered, repeat the procedure. Secure the air cleaner assembly, then reconnect the Ignition Coil, spark plug wires, then reconnect the electrical connector, tighten the cap and screws of the Distributor, tighten the clamp and the bolt of the Distributor until it is secured. Lastly, use a scan tool to see if there are any dtc codes, specifically p1345 which inform about improper installation, and observe the camshaft retard offset value.