ChevyParts

My Garage

My Account

Cart

OEM GMC Yukon Timing Chain

Engine Timing Chain- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

6 Timing Chains found

GMC Yukon Timing Chain Part Number: 12646386

$63.56 MSRP: $108.21You Save: $44.65 (42%)

GMC Yukon Timing Chain Part Number: 14087014

$55.75 MSRP: $94.91You Save: $39.16 (42%)Ships in 1-2 Business Days

GMC Yukon Timing Chain Part Number: 12646387

$63.56 MSRP: $108.21You Save: $44.65 (42%)Ships in 1-3 Business DaysGMC Yukon Timing Chain Part Number: 55515943

$30.22 MSRP: $47.32You Save: $17.10 (37%)GMC Yukon Timing Chain Part Number: 55489211

$15.27 MSRP: $23.91You Save: $8.64 (37%)Ships in 1-3 Business DaysGMC Yukon Timing Chain Part Number: 14022647

$87.49 MSRP: $148.95You Save: $61.46 (42%)

GMC Yukon Timing Chain

Want to cut long-term maintenance and repair costs? Choose OEM Timing Chain. Those parts deliver top durability you can trust. On our site, you'll find a huge catalog of genuine GMC Yukon parts. Prices are unbeatable, so you can keep more in your pocket. Every OEM GMC Yukon Timing Chain includes a manufacturer's warranty. You can also get an easy return policy that keeps buying risk free. Fast delivery, get your car on the road quickly. It's simple to search, compare, and order. Stop guessing about quality or fit. Order today and save with parts that last.

The Timing Chain in GMC Yukon automobiles is responsible for the correct interoperation of camshaft and crankshaft, thus maintaining the correct valve timing of the engines. Timing chains, which are commonly manufactured from metal, are preferred to rubber timing belts because the former almost do not wear. Lubrication problems or tensioner failures are some of the problems that are known to cause difficulties in the timing chain system which will manifest as a rattling sound from the car's engine. For the pushrod engines, a short chain drive is used instead of a gear drive given the many torque reversal, it is a more reliable and less noisy for the specific type of engines.

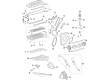

GMC Yukon Timing Chain Parts and Q&A

- Q: What tools are required to replace the timing chain and sprocket on engines LC9, LMG, LY2, and LY5 (4.8L and 5.3L) on GMC Yukon?A:Engine replacement of Timing Chain and sprocket on lc9 lmg ly2 ly5 (4.8L and 5.3L) requires these necessary tool collection: en 46330 Timing Chain Tensioner retaining pin (EN 46330), j 8433 puller bar (J 8433), j 41478 crankshaft front oil seal installer (J 41478), j 41558 crankshaft sprocket remover (J 41558), j 41665 crankshaft balancer and sprocket installer (J 41665), j 41816-2 the proper tools for Timing Chain and sprocket replacement on engines lc9, lmg, ly2, and ly5 (4.8L and 5.3L) include en 46330 Timing Chain Tensioner retaining pin (EN 46330), j 8433 puller bar (J 8433), j 41478 crankshaft front oil seal installer (J 41478), j 41558 crankshaft sprocket remover (J 41558), j 41665 crankshaft balancer and sprocket installer (J 41665), j 41816 install the j 42386-a Flywheel holding tool after removing the Oil Pump and Starter motor while checking that the tool's teeth fit properly with the engine Flywheel. Once the j 42386-a tool and its bolts are in place tighten the hardware to 50 n.m (37 lb ft). The crankshaft rotation should align the timing marks between the crankshaft and camshaft sprockets. At this point, extract the camshaft sprocket bolt, camshaft sprocket and Timing Chain and Timing Chain Tensioner. Begin by using tools j41816-2 and j41558 and j8433 to remove the crankshaft sprocket before proceeding to remove the crankshaft sprocket key if needed. Begin installation by placing the key inside the crankshaft keyway then tapping it further in before installing the sprocket by aligning the key with the sprocket keyway. The j 41478 and j 41665 tools will help position the crankshaft sprocket so it touches the crankshaft flange. Install the en 46330 before you fit the Timing Chain Tensioner along with its bolts. Tighten these fasteners to 25 n.m (18 lb ft). Check that the teeth of both sprockets mesh correctly and the alignment marks on the crankshaft sprocket and camshaft match accordingly. The camshaft sprocket should face the 6 o'clock direction before its installation with the Timing Chain and bolt and subsequent inspection of alignment quality. Begin by removing the en 46330 then gradually tighten the camshaft sprocket bolt to 90 n.m (66 lb ft) and continue to an additional 40-degree torque using the j 45059. Complete the installation by removing j 42386-a and its bolts then repositioning the Starter motor and Oil Pump.