ChevyParts

My Garage

My Account

Cart

OEM Buick Brake Disc

Disc Rotor- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

83 Brake Discs found

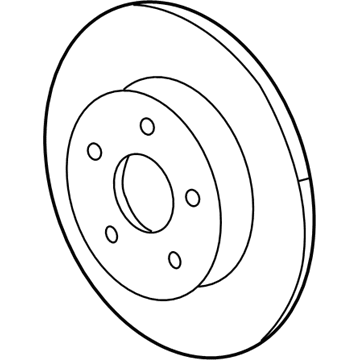

Buick Rotor, Rear Part Number: 23118533

$92.92 MSRP: $255.40You Save: $162.48 (64%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Rotor-Rear Brake; Brake Rotor; Rotor, Front And Rear Wheel Brake

- Position: Rear

- Replaces: 13501314

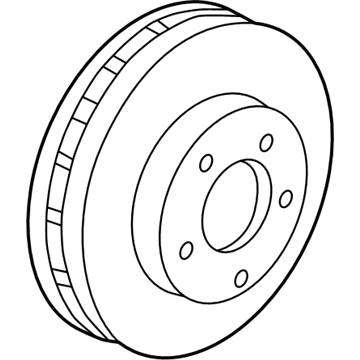

Buick Rotor, Front Part Number: 23118275

$196.96 MSRP: $385.62You Save: $188.66 (49%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Rotor-Front Brake; Disc Brake Hardware Kit; Brake Rotor; Rotor, Front And Rear Wheel Brake

- Position: Front

- Replaces: 13502057

Buick Rotor, Rear Part Number: 23118282

$95.09 MSRP: $261.32You Save: $166.23 (64%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Rotor-Rear Brake (Coated); Brake Rotor; Rotor, Front And Rear Wheel Brake

- Position: Rear

- Replaces: 13505762

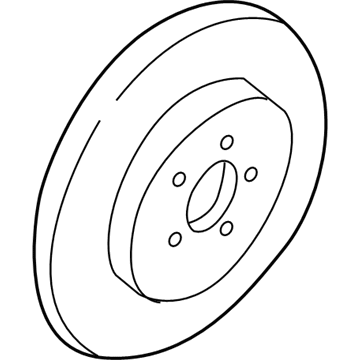

Buick Rotor, Front Part Number: 19181002

$63.19 MSRP: $173.69You Save: $110.50 (64%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Rotor Assembly, Front Brake; Disc Brake Hardware Kit; Brake Rotor; Rotor, Front And Rear Wheel Brake

- Position: Front

- Replaces: 18060664

Buick Rotor, Front Part Number: 25826103

$58.78 MSRP: $161.55You Save: $102.77 (64%)Ships in 1 Business DayProduct Specifications- Other Name: Rotor Assembly-Front Brake; Disc Brake Hardware Kit; Brake Rotor; Rotor, Front And Rear Wheel Brake

- Position: Front

- Replaces: 18060665

Buick Rotor, Rear Part Number: 19303821

$47.79 MSRP: $123.66You Save: $75.87 (62%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Rotor, Rear Brake (Coated); Brake Rotor; Rotor, Front And Rear Wheel Brake

- Position: Rear

- Replaces: 10377634, 25999701

Buick Rotor, Rear Part Number: 13528069

$116.16 MSRP: $218.14You Save: $101.98 (47%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Rotor-Rear Brake (Coated); Disc Brake Hardware Kit; Brake Rotor; Rotor, Front And Rear Wheel Brake

- Position: Rear

- Replaces: 13509676

Buick Rotor, Rear Part Number: 13507431

$51.99 MSRP: $92.85You Save: $40.86 (45%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Rotor-Rear Brake; Disc Brake Hardware Kit; Brake Rotor; Rotor, Front And Rear Wheel Brake

- Position: Rear

Buick Rotor, Front Part Number: 13512340

$65.49 MSRP: $179.99You Save: $114.50 (64%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Rotor-Front Brake; Disc Brake Hardware Kit; Brake Rotor; Rotor, Front And Rear Wheel Brake

- Position: Front

Buick Rotor Part Number: 88964180

$115.12 MSRP: $216.17You Save: $101.05 (47%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Rotor, Front And Rear Wheel Brake; Brake Rotor

- Position: Rear

Buick Brake Rotor, Front Part Number: 19174917

$50.14 MSRP: $89.54You Save: $39.40 (44%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Rotor Assembly, Front Brake; Disc Brake Hardware Kit; Rotor; Rotor, Front And Rear Wheel Brake

- Position: Front

- Replaces: 01642177, 18060207, 1642177, 18027718

Buick Rotor Part Number: 19303830

$57.91 MSRP: $159.19You Save: $101.28 (64%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Rotor, Front And Rear Wheel Brake; Brake Rotor

- Position: Rear

- Replaces: 18060232, 25956847, 88965647, 18021354

Buick Rotor, Front Part Number: 13515289

$34.95 MSRP: $63.26You Save: $28.31 (45%)Product Specifications- Other Name: Rotor-Front Brake (Coated); Brake Rotor

- Position: Front

- Replaced by: 13517843

Buick Rotor, Rear Part Number: 23381489

$111.51 MSRP: $201.83You Save: $90.32 (45%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Rotor-Rear Brake (Coated); Brake Rotor; Rotor, Front And Rear Wheel Brake

- Position: Rear

Buick Rotor, Front Part Number: 13598076

$113.84 MSRP: $206.04You Save: $92.20 (45%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Rotor-Front Brake; Disc Brake Hardware Kit; Brake Rotor; Rotor, Front And Rear Wheel Brake

- Position: Front

Buick Rotor, Front Part Number: 19303816

$129.32 MSRP: $234.07You Save: $104.75 (45%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Rotor, Front Brake; Disc Brake Hardware Kit; Brake Rotor; Rotor, Front And Rear Wheel Brake

- Position: Front

- Replaces: 18048698, 25983740

Buick Rotor, Front Part Number: 25826102

$93.28 MSRP: $168.84You Save: $75.56 (45%)Ships in 1 Business DayProduct Specifications- Other Name: Rotor Assembly-Front Brake; Disc Brake Hardware Kit; Brake Rotor; Rotor, Front And Rear Wheel Brake

- Position: Front

- Replaces: 21998532

Buick Rotor Part Number: 19303807

$63.46 MSRP: $123.15You Save: $59.69 (49%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Rotor, Front And Rear Wheel Brake; Brake Rotor

- Position: Rear

- Replaces: 25982106, 20880098

Buick Rotor, Rear Part Number: 13501313

$126.13 MSRP: $244.80You Save: $118.67 (49%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Rotor-Rear Brake; Brake Rotor; Rotor, Front And Rear Wheel Brake

- Position: Rear

- Replaced by: 23118537

Buick Rotor, Rear Part Number: 13506241

$111.67 MSRP: $200.30You Save: $88.63 (45%)Product Specifications- Other Name: Rotor-Rear Brake (Coated); Brake Rotor; Rotor, Front And Rear Wheel Brake

- Position: Rear

| Page 1 of 5 |Next >

1-20 of 83 Results

Buick Brake Disc

Want to cut long-term maintenance and repair costs? Choose OEM Brake Disc. Those parts deliver top durability you can trust. On our site, you'll find a huge catalog of genuine Buick parts. Prices are unbeatable, so you can keep more in your pocket. Every OEM Buick Brake Disc includes a manufacturer's warranty. You can also get an easy return policy that keeps buying risk free. Fast delivery, get your car on the road quickly. It's simple to search, compare, and order. Stop guessing about quality or fit. Order today and save with parts that last.

Buick Brake Disc Parts Questions & Experts Answers

- Q: How to replace the front brake disc on Buick LaCrosse?A:Vehicle maintenance requires users to lift and stabilize the vehicle before they remove the tire and wheel assembly when replacing a front Brake Disc. A c-clamp should compress the Piston toward the caliper bore which lets the caliper slide away from the disc and then you can remove the c-clamp. After disconnecting the caliper bracket bolts the mechanic should remove the brake caliper and caliper mounting bracket assembly from the suspension knuckle while using heavy mechanic's wire for supportive equipment to avoid impacting the hydraulic brake hose. Mark the relationship between the Brake Disc and wheel studs before taking it off. The wheel hub resurfacing kit (J42450-A) should be used to clean rust or corrosion from the hub/axle flange before cleaning the Brake Disc mating surfaces with the rotor resurfacing kit (J41013). Before integrating the Brake Disc into the hub/axle flange check all mating surfaces are clear of debris then use the matchmark to establish proper disc orientation. Measure the lateral runout of the assembled Brake Disc after installation when possible and adjust if measurements exceed set specifications. Reinstall the brake caliper and bracket to the suspension knuckle before installing the tire and wheel assembly followed by lowering the vehicle and conducting pad and disc burnishing when Brake Disc replacement or refinishing took place.

- Q: How to service and repair the Brake Disc using the J41013 and J42450-A kits on Buick LeSabre?A:Begin the repair of the Brake Disc. Look at every disc Brake Disc to see if the surface is worn out, if there is lateral runout, and make sure it is still above the minimum allowed size after resurfacing. When refinishing because the parts are corroded, cracked, or scored beyond standards, fit the Brake Disc to the brake lathe as the manufacturer says, and check that everything is clean. Let the lathe run while you move the cutting tools toward the disc friction surfaces and look at the witness mark to make sure they are mounted properly. Use the manufacturer's guide to refinish the disc, keep checking the thickness after every cut, and fit a new disc if it gets too thin. You can get a non-directional finish by using the recommended speed and 120 grit aluminum oxide sandpaper if you have a non-directional tool, or with 150 grit sandpaper and a sanding block if you don't. Once you are done, wipe each friction surface with denatured alcohol or brake cleaner, then take the disc off the lathe.

- Q: How to replace the front brake disc on Buick Regal?A:Per instructions available in goodwrench brake parts cleaner kit (P/N 123777981), remove the protective coating from new disc friction faces by wiping with specialized cleaning solution and lint-free cloths. Never use gasoline, kerosene, or oil-based products that may contaminate the disc. Start by safely lifting the vehicle and detach the tire and wheel. Keep the brake caliper safe when you remove it from its mount without disconnecting the hydraulic brake hose through wire support. First secure the brake caliper and bracket as one unit using mechanic's wire. After that remove the Brake Disc from the vehicle. Remove all rust or foreign material from the wheel bearing flange and Brake Disc contact areas by using j 41013 disc resurfacing kit product. Install the new Brake Disc first and put on the caliper bracket afterward before replacing the tire and wheel which needs to be done below vehicle level.