ChevyParts

My Garage

My Account

Cart

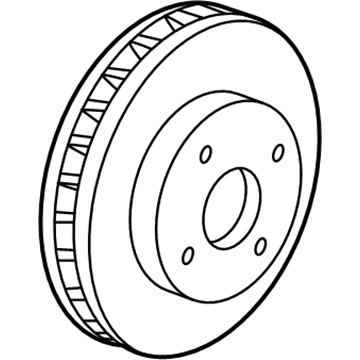

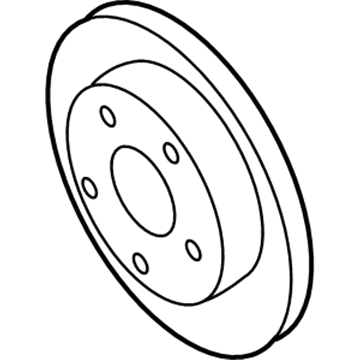

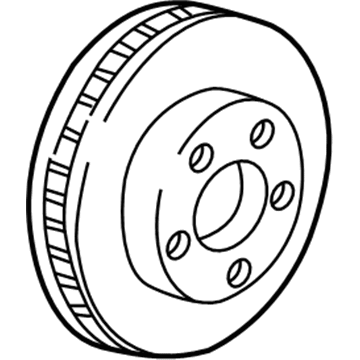

OEM Buick LeSabre Brake Disc

Disc Rotor- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

10 Brake Discs found

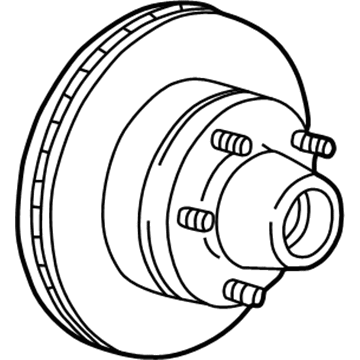

Buick LeSabre Hub & Rotor, Front Part Number: 19174911

$110.00 MSRP: $196.42You Save: $86.42 (44%)Ships in 1-3 Business DaysBuick LeSabre Rotor, Front Part Number: 19303832

$48.29 MSRP: $146.71You Save: $98.42 (68%)Buick LeSabre Brake Rotor, Front Part Number: 19174917

$50.14 MSRP: $89.54You Save: $39.40 (44%)Ships in 1-3 Business Days

Buick LeSabre Rotor, Front Part Number: 19202731

Buick LeSabre Brake Rotor, Front Part Number: 19211904

Buick LeSabre Brake Rotor, Front Part Number: 18060226

Buick LeSabre Rotor Part Number: 18040482

Buick LeSabre Rotor Part Number: 18060236

Buick LeSabre Brake Rotor, Front Part Number: 18060234

Buick LeSabre Brake Rotor, Front Part Number: 19303831

$34.00 MSRP: $139.00You Save: $105.00 (76%)

Buick LeSabre Brake Disc

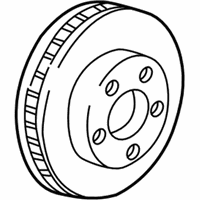

Want to cut long-term maintenance and repair costs? Choose OEM Brake Disc. Those parts deliver top durability you can trust. On our site, you'll find a huge catalog of genuine Buick LeSabre parts. Prices are unbeatable, so you can keep more in your pocket. Every OEM Buick LeSabre Brake Disc includes a manufacturer's warranty. You can also get an easy return policy that keeps buying risk free. Fast delivery, get your car on the road quickly. It's simple to search, compare, and order. Stop guessing about quality or fit. Order today and save with parts that last.

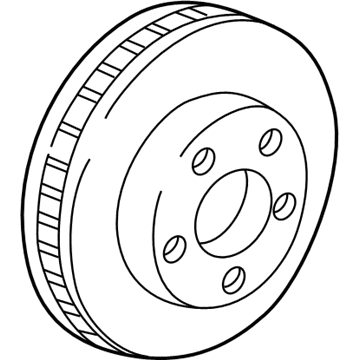

Brake Disc is one of the important systems of Buick LeSabre that reflects the whole picture of this car and its performance capability. The Brake Disc is specially made for different models of the Buick LeSabre; by improving the car's braking system, drivers can safely maneuver through every terrain. The kit has thick brake pads that have good friction material that is embedded on aextended metal foundation. This design not only provides the uniformity of wear but also has built-in wear measuring devices that let the drivers know it is time to replace, thus avoiding any jeopardizing of safety. The Buick LeSabre Brake Disc is quite advantageous, especially for the performance-oriented drivers as they get an opportunity to select better quality pad which guarantees better stopping power from the automobiles particularly when used under high-performance conditions. Also, the supplies of vital hardware items such as clips, springs, shims play critical roles in the effective functioning of the pads, thus improving the performance of Buick LeSabre. The Buick LeSabre is actually one of the large cars that customers love to use because of the long history, rich experience of the automobile industry and the advanced Brake Disc system. Due to the reliability, safety and performance aspects involved in the Buick LeSabre Brake Disc particular model, owning a LeSabre should be appreciated as an investment that can provide many more inspiring driving moments to enthusiasts of this model.

Buick LeSabre Brake Disc Parts and Q&A

- Q: How to service and repair front brake discs on Buick LeSabre?A:Brake rotor refinishing becomes necessary only when any of the following conditions exist: excessive corrosion, pitting, cracks, heat spots, excessive bluing discoloration, scoring beyond maximum allowable specifications, lateral runout exceeding specifications, or thickness variation beyond specifications. When refinishing is needed for brake rotors use the Hub Cleaning Kit (J42450-A) to clean away any corrosion that exists on the brake rotor hub. Install the brake rotor to the brake lathe according to manufacturer guidelines by properly securing the anti-vibration accessories. Advanced through the lathe speed while guiding the cutting tools to touch the rotor friction surfaces and verify that mounting is correct from the witness mark. The rotor needs to be remounted when the witness mark fails to reach the three-quarter distance around its perimeter. The rotor refining process must follow manufacturer instructions while the final thickness measurement determines whether replacement is needed. The process to acquire a non-directional finish requires following speed parameters and using 120 grit aluminum oxide sandpaper through a non-directional finishing tool or 150 grit aluminum oxide sandpaper with a sanding block when no finishing tool is present. Use denatured alcohol or a brake cleaner equivalent to wipe down all friction areas immediately following completion. Remove the brake rotor from the lathe after finishing then use the Rotor/Drum Flange Resurfacing Kit (J41013) to clean any corrosion from the wheel bearing flange to prevent brake system pulsation and increased lateral runout.

- Q: How to replace the front brake disc on Buick LeSabre?A:In order to change out the front brake rotor, remove the tire and wheel assembly. Use heavy mechanic's wire or an equivalent to support the brake caliper each time it is removed from its mount, but the hydraulic flexible brake hose is still attached to it, as any failure to do would damage the hose and cause it to leak brake fluid. Next, free the brake caliper from its mounting bracket and suspend it after which you should move on to unfastening the Brake Caliper Bracket assembly and the brake rotor. Clean any rust or contaminants from the wheel bearing flange and brake rotor mating surfaces with the j42450-a, then put the new brake rotor onto the wheel studs onto the wheel bearing flange, followed by the Brake Caliper Bracket assembly, and fasten the brake caliper over the bracket assembly. Finally, reassemble the tire and wheel assembly.