ChevyParts

My Garage

My Account

Cart

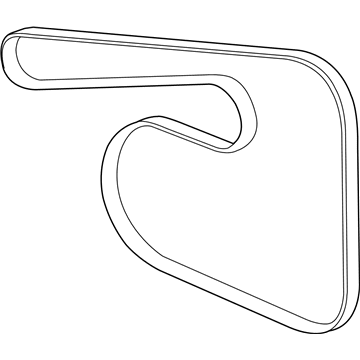

OEM Buick Drive Belt

Serpentine Belt- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

85 Drive Belts found

Buick Serpentine Belt Part Number: 12578274

$37.95 MSRP: $67.78You Save: $29.83 (45%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Belt, Drive; Serpentine Belt Drive Kit; Accessory Drive Belt; Drive Belt; V-Belt

Buick Serpentine Belt Part Number: 12588407

$41.26 MSRP: $77.49You Save: $36.23 (47%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Belt, Drive; Serpentine Belt Drive Kit; Accessory Drive Belt; Drive Belt; V-Belt

Buick Serpentine Belt Part Number: 12593774

$36.46 MSRP: $79.59You Save: $43.13 (55%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Belt, Drive; Serpentine Belt Drive Kit; Accessory Drive Belt; Drive Belt; V-Belt

- Replaces: 12575216, 12569531

Buick Serpentine Belt Part Number: 12646194

$43.55 MSRP: $77.78You Save: $34.23 (45%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Belt-Generator & A/C Compressor & Power Steering Pump; Serpentine Belt Drive Kit; Drive Belt; V-Belt; Belt, Drive

- Replaces: 12589908, 12616673

Buick Serpentine Belt Part Number: 12654815

$25.13 MSRP: $44.88You Save: $19.75 (45%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Belt, Drive; Serpentine Belt Drive Kit; Accessory Drive Belt; Drive Belt; V-Belt

Buick Serpentine Belt Part Number: 12596249

$55.17 MSRP: $98.52You Save: $43.35 (44%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Belt, Drive; Serpentine Belt Drive Kit; Accessory Drive Belt; Drive Belt; V-Belt

Buick Serpentine Belt Part Number: 19355282

$39.35 MSRP: $70.26You Save: $30.91 (44%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Belt, Water Pump & A/C Compressor & Generator & Power Steering Pump; Serpentine Belt Drive Kit; Drive Belt; V-Belt; Belt; Belt, Drive

- Replaces: 12588413, 12569591, 24505853, 24507294

Buick Serpentine Belt Part Number: 55512900

$19.54 MSRP: $34.90You Save: $15.36 (45%)Product Specifications- Other Name: Belt-Accessory Drive Primary; Serpentine Belt Drive Kit; Drive Belt; V-Belt; Belt, Drive

- Replaced by: 25203354

Buick Serpentine Belt Part Number: 12604478

$33.47 MSRP: $59.76You Save: $26.29 (44%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Belt, Drive; Serpentine Belt Drive Kit; Accessory Drive Belt; Drive Belt; V-Belt

Buick Serpentine Belt Part Number: 12588414

$33.81 MSRP: $60.37You Save: $26.56 (44%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Belt, Drive; Serpentine Belt Drive Kit; Accessory Drive Belt; Drive Belt; V-Belt; Belt

- Replaces: 12569592, 24504201

Buick Serpentine Belt Part Number: 12588410

$29.50 MSRP: $55.42You Save: $25.92 (47%)Product Specifications- Other Name: Belt, Drive; Serpentine Belt Drive Kit; Accessory Drive Belt; Drive Belt; V-Belt

- Replaces: 24507815, 12569377

Buick Serpentine Belt Part Number: 12664598

$19.43 MSRP: $34.70You Save: $15.27 (45%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Belt, Drive; Serpentine Belt Drive Kit; Accessory Drive Belt; Drive Belt; V-Belt

- Replaces: 12652186

Buick Serpentine Belt Part Number: 55488926

$14.24 MSRP: $25.42You Save: $11.18 (44%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Belt, Drive; Serpentine Belt Drive Kit; Drive Belt; V-Belt

- Replaced by: 12732747

Buick Serpentine Belt Part Number: 19244949

$37.20 MSRP: $66.45You Save: $29.25 (45%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Belt, Water Pump, A/C Compressor, Generator, Power Steering Pump; Serpentine Drive Kit; Accessory Drive Belt.; Belt, Drive

- Replaces: 12575215, 12569543

Buick Serpentine Belt Part Number: 12627134

$19.61 MSRP: $35.03You Save: $15.42 (45%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Belt, Drive; Serpentine Belt Drive Kit; Accessory Drive Belt; Drive Belt; V-Belt

Buick Serpentine Belt Part Number: 19355375

$39.34 MSRP: $81.59You Save: $42.25 (52%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Belt, Drive; Serpentine Belt Drive Kit; Drive Belt; V-Belt; Fan Belt

- Replaces: 24502138, 88986816, 24501203, 24502761, 12555073

Buick Serpentine Belt Part Number: 55569810

$19.25 MSRP: $34.38You Save: $15.13 (45%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Belt, Drive; Serpentine Belt Drive Kit; Accessory Drive Belt; Drive Belt; V-Belt

Buick Serpentine Belt Part Number: 19172684

$37.32 MSRP: $66.65You Save: $29.33 (45%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Belt, Water Pump & A/C Compressor & Generator & Power Steering Pump; Serpentine Belt Drive Kit; Drive Belt; V-Belt; Belt, Drive

- Replaces: 24505327, 88986812

Buick Serpentine Belt Part Number: 12687927

$9.24 MSRP: $16.49You Save: $7.25 (44%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Belt-Accessory Drive Primary; Serpentine Belt Drive Kit; Drive Belt; V-Belt

- Replaced by: 25206736

Buick Serpentine Belt Part Number: 12677962

$20.90 MSRP: $37.32You Save: $16.42 (44%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Belt-Accessory Door Auxiliary; Serpentine Belt Drive Kit; Drive Belt; V-Belt; A/C Belt; Belt, Drive

| Page 1 of 5 |Next >

1-20 of 85 Results

Buick Drive Belt

Choose OEM Drive Belt, you're making the optimal decision for superior quality and perfect performance. You can feel confident because each component goes through stringent quality checks. Every part is carefully built to comply with Buick's factory specifications. You'll enjoy a smooth, worry-free installation that fits just right. At ChevyPartsGiant.com, you'll find it easy to get top-quality OEM Buick Drive Belt. You can shop at highly competitive prices and protect your budget. All our genuine Buick parts include a dependable manufacturer's warranty. You'll also appreciate our straightforward return policy and swift delivery services for extra convenience.

Buick Drive Belt Parts and Q&A

- Q: How to Service and Repair the Drive Belt on Buick LaCrosse?A:Raising the vehicle should be the starting point for Drive Belt replacement. The next step requires removal of the right engine splash shield. Tools are used to unlock tension on the Drive Belt tensioner through clockwise rotation before removing the Drive Belt from each of the generator and accessory drive pulleys. Post-removal the technician should let go of the tensioner while maintaining a careful pace. The first step for installation starts with putting back the right engine splash shield followed by lowering the vehicle. The first step for Drive Belt replacement involves positioning it on the accessory drive pulley followed by clockwise tensioner rotation and guide it to the generator. A carefull alignment of the Drive Belt with the accessory drive pulleys' grooves should be confirmed before the tensioner release is made gradually.

- Q: How to replace the drive belt on Buick Regal?A:A 15 mm box end wrench on the pulley nut enables lift or rotation of the drive belt tensioner which allows drive belt removal. The 15 mm box end wrench on the pulley nut should be used to lift or rotate the drive belt tensioner before installing the new drive belt.