ChevyParts

My Garage

My Account

Cart

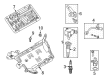

OEM Buick Spark Plug

Ignition Spark Plug- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

20 Spark Plugs found

Buick Spark Plug Part Number: 12681665

$9.22 MSRP: $16.46You Save: $7.24 (44%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Spark Plug Assembly-Gasoline Engine Ignition; Spark Plug, Spark Ignition; Spark Plug,Glow

- Replaced by: 12681664

- Replaces: 25162555, 12607234, 25315018, 25162556, 19256067, 89017883

Buick Spark Plug Part Number: 12681657

$9.22 MSRP: $16.46You Save: $7.24 (44%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Spark Plug Assembly-Gasoline Engine Ignition; Spark Plug, Spark Ignition; Spark Plug,Glow

- Replaces: 12611882

Buick Spark Plug Part Number: 19300872

$7.57 MSRP: $13.52You Save: $5.95 (45%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Spark Plug Assembly; Spark Plug, Spark Ignition; Spark Plug,Glow

- Replaces: 12597464, 92220447

Buick Spark Plug Part Number: 12683541

$9.41 MSRP: $16.80You Save: $7.39 (44%)Product Specifications- Other Name: Spark Plug Assembly-Gasoline Engine Ignition; Spark Plug,Glow

- Replaces: 55490097

Buick Spark Plug Part Number: 12681664

$9.22 MSRP: $16.46You Save: $7.24 (44%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Spark Plug Assembly-Gasoline Engine Ignition; Spark Plug, Spark Ignition; Spark Plug,Glow

- Replaces: 12568387, 25330840, 12565030, 25161444

Buick Spark Plug Part Number: 12681662

$11.36 MSRP: $20.28You Save: $8.92 (44%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Spark Plug, Spark Ignition; Spark Plug,Glow

- Replaces: 12591131

Buick Spark Plug Part Number: 12681660

$9.22 MSRP: $16.46You Save: $7.24 (44%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Spark Plug Assembly-Gasoline Engine Ignition; Spark Plug, Spark Ignition; Spark Plug,Glow

- Replaces: 12622561

Buick Spark Plug Part Number: 12681658

$9.22 MSRP: $16.46You Save: $7.24 (44%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Spark Plug Assembly-Gasoline Engine Ignition; Spark Plug,Glow

- Replaces: 12617309, 12590701, 12620540

Buick Spark Plug Part Number: 12681656

$9.91 MSRP: $17.70You Save: $7.79 (45%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Spark Plug Assembly-Gasoline Engine Ignition; Spark Plug,Glow

- Replaces: 55585517, 55576026

Buick Spark Plug Part Number: 12680074

$9.55 MSRP: $17.06You Save: $7.51 (45%)Product Specifications- Other Name: Spark Plug Assembly-Gasoline Engine Ignition; Spark Plug,Glow

- Replaces: 12627160

Buick Spark Plug Part Number: 12646780

$10.35 MSRP: $18.48You Save: $8.13 (44%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Spark Plug Assembly; Spark Plug,Glow

Buick Spark Plug Part Number: 19302723

$2.81 MSRP: $5.02You Save: $2.21 (45%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Spark Plug Assembly; Spark Plug, Spark Ignition; Spark Plug,Glow

- Replaced by: 19354417

Buick Spark Plug Part Number: 19301814

$9.53 MSRP: $17.02You Save: $7.49 (45%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Spark Plug Assembly; Spark Plug,Glow

- Replaces: 19256624, 12565996

Buick Spark Plug Part Number: 12681663

$9.22 MSRP: $16.46You Save: $7.24 (44%)Product Specifications- Other Name: Spark Plug Assembly-Gasoline Engine Ignition; Spark Plug, Spark Ignition; Spark Plug,Glow

- Replaces: 12598004, 12625058

Buick Spark Plug Part Number: 12681659

$9.22 MSRP: $16.46You Save: $7.24 (44%)Product Specifications- Other Name: Spark Plug Assembly-Gasoline Engine Ignition; Spark Plug,Glow

- Replaces: 12647827, 12626906

Buick Spark Plug Part Number: 55504354

$11.44 MSRP: $20.42You Save: $8.98 (44%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Spark Plug Assembly-Gasoline Engine Ignition; Spark Plug,Glow

Buick Spark Plug Part Number: 19300875

$7.71 MSRP: $13.76You Save: $6.05 (44%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Spark Plug Assembly; Spark Plug, Spark Ignition; Spark Plug,Glow

- Replaces: 19208525, 19244468, 19158033, 19158029, 5614248, 5614235, 05614248, 19244463, 19207828, 05614235

Buick Spark Plug Part Number: 12688094

$10.33 MSRP: $18.44You Save: $8.11 (44%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Spark Plug Assembly-Gasoline Engine Ignition; Spark Plug, Spark Ignition; Spark Plug,Glow

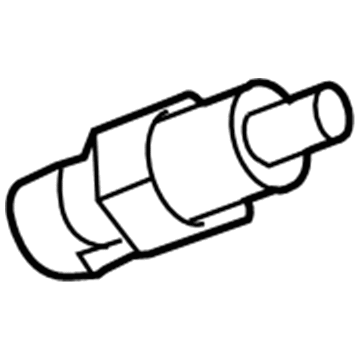

Buick Glow Plug Part Number: 5613826

Product Specifications- Other Name: Plug-Glow; Diesel Glow Plug; Glow Plug,Glow

Buick Spark Plug Part Number: 12571535

Product Specifications- Replaces: 12561466

Buick Spark Plug

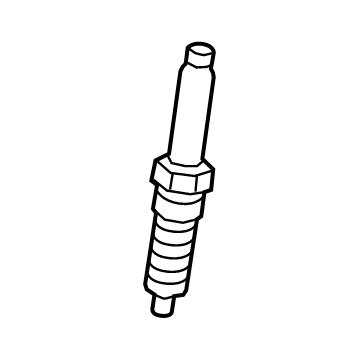

Want to cut long-term maintenance and repair costs? Choose OEM Spark Plug. Those parts deliver top durability you can trust. On our site, you'll find a huge catalog of genuine Buick parts. Prices are unbeatable, so you can keep more in your pocket. Every OEM Buick Spark Plug includes a manufacturer's warranty. You can also get an easy return policy that keeps buying risk free. Fast delivery, get your car on the road quickly. It's simple to search, compare, and order. Stop guessing about quality or fit. Order today and save with parts that last.

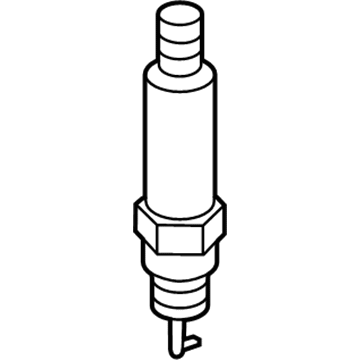

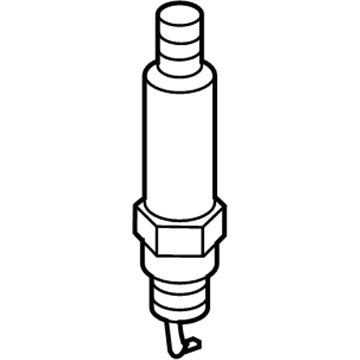

Buick Spark Plug Parts Questions & Experts Answers

- Q: How to replace the spark plugs in an engine on Buick Lucerne?A:Replace spark plugs by beginning with the removal of the intake manifold cover if required. Position each Spark Plug wire before removing the connection by twisting its Spark Plug boot 1/2 turn counterclockwise followed by lifting the heat shield gently with the Spark Plug boot removal tool (J 38491). Proceed to remove the air inlet grille once the step is finished. The process for removing Spark Plug Wires must repeat itself at the rear engine position. Use the specific tool to take out all spark plugs from the engine block. Step one of installation requires measuring the gap of new spark plugs before checking against the specified gap requirements for adjustment. Insert the spark plugs into their proper positions then tighten them to 15 n.m (11 lb ft). Return Spark Plug Wires to the rear spark plugs first followed by air inlet grille installation then proceed with sparking wires installation to front spark plugs if required. Place all intake manifold cover back into position if required.

- Q: How to replace a spark plug correctly on Buick LaCrosse?A:The Spark Plug replacement process should begin with turning off the ignition before removing the Ignition Coil. Prior to removing the Spark Plug you must clean its recess area to stop external substances from entering the Cylinder Head space and creating possible engine framework failure and thread contamination. A thread chaser tools should be used to clean all contamination from the threaded areas. Before proceeding with Spark Plug removal operate compressed air through the Spark Plug cavity until the engine reaches normal temperature because removing plugs from a hot engine might result in thread restricting. Dismantle the Spark Plug after obtaining readiness status. Install only the spark plugs that match the vehicle's specifications precisely because wrong plug types create severe damage to the engine components. A round feeler gauge must be used to check the gap of new and reconditioned spark plugs until it reaches the specified Spark Plug gap. Look for easy thread insertion and complete seat placement of the Spark Plug into the Cylinder Head by using a thread chaser when needed to prevent damage from cross-threading or poor seating which could result in overheating or damaged threads. Fit the Spark Plug before torquing it to 20 n.m (15 lb ft) and reinstall the Ignition Coil.

- Q: What steps should be taken to ensure the correct installation and inspection of spark plugs to avoid driveability issues on Buick Regal?A:Executions must use the right Spark Plug to prevent drivability problems and should verify that the plug's heat range is correct to avoid fouling from cold plugs or pre-ignition damages from hot plugs. Check the terminal post and verify it has no damage along with checking its stability by gentle movements; it should not move. Inspect the insulator for flashover or carbon tracking because electrical charge moves between terminal post and ground while checking the Spark Plug boot for damage and examining the recess area of Cylinder Head for moisture which conducts arcing. Examine the insulator for cracks that might short-circuit electrical charge towards the electrodes while also checking that the center electrode distance from the side electrode matches product specifications (3, 4). Torque the spark plugs correctly since inadequate torque level can result in operational problems yet excessive torques may endanger the insulator. Inspect the insulator tip for tracking signs while checking the side electrode for wear or breakage and examine the center electrode for loose or broken components by shaking it to hear a rattling sound. Check for gaps (3, 4) due to accumulating deposits that close the space while also verifying electrode conditions (3, 4) regarding missing or worn platinum pads together with signs of excessive fouling. The proper installation of spark plugs depends on having a debris-free area inside the Cylinder Head Spark Plug recess where poor seating could occur. During normal operation the Spark Plug features brown to grayish-tan appearance with trace white powdery substances but carbon fouling develops as dry black soot from rich fuel mixtures among other causes such as leaking fuel injectors and excessive fuel pressure. Restricted air filters alongside incorrect combustion issues with reduced ignition system voltage and weak coils, worn ignition wires and improper Spark Plug gap and prolonged idling time all contribute to carbon fouling. Oil and coolant as well as additive deposits can decrease spark intensity since they develop glaze layers on top of the electrode.