ChevyParts

My Garage

My Account

Cart

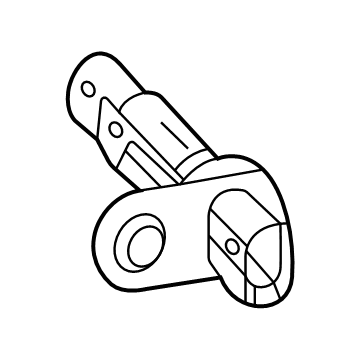

OEM Buick Crankshaft Position Sensor

Engine Crankshaft Position Sensor- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

37 Crankshaft Position Sensors found

Buick Crankshaft Position Sensor, Green Line Part Number: 12588992

$33.33 MSRP: $62.60You Save: $29.27 (47%)Ships in 1 Business DayProduct Specifications- Other Name: Sensor Assembly-Crankshaft Position; Engine Crankshaft Position Sensor; Crankshaft Sensor

- Replaced by: 12674703

Buick Crankshaft Position Sensor Part Number: 12662533

$14.24 MSRP: $25.78You Save: $11.54 (45%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Sensor Assembly-Crankshaft Position; Crankshaft Sensor; Sensor, Distributor (Also Knock Sensor)

- Replaces: 12638559

Buick Crankshaft Position Sensor Part Number: 10496122

$19.71 MSRP: $30.86You Save: $11.15 (37%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Sensor, Distributor (Also Knock Sensor)

Buick Crankshaft Position Sensor Part Number: 12664495

$17.01 MSRP: $31.94You Save: $14.93 (47%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Sensor Assembly-Crankshaft Position; Crankshaft Sensor; Sensor, Distributor (Also Knock Sensor)

Buick Crankshaft Position Sensor Part Number: 55492970

$31.23 MSRP: $58.64You Save: $27.41 (47%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Sensor Assembly-Crankshaft Position; Crankshaft Sensor; Sensor, Distributor (Also Knock Sensor)

Buick Crankshaft Position Sensor Part Number: 1103703

$44.56 MSRP: $90.52You Save: $45.96 (51%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Sensor Assembly; Engine Crankshaft Position Sensor; Crankshaft Sensor

- Replaced by: 12567712

Buick Knock Sensor Part Number: 12663209

$4.12 MSRP: $7.73You Save: $3.61 (47%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Sensor, Distributor (Also Knock Sensor)

Buick Crankshaft Position Sensor Part Number: 12706708

$7.32 MSRP: $13.08You Save: $5.76 (45%)Product Specifications- Other Name: Sensor Assembly-Crankshaft Position; Crankshaft Sensor; Sensor, Distributor (Also Knock Sensor)

- Replaces: 55507118

Buick Crankshaft Position Sensor Part Number: 25535480

$24.11 MSRP: $37.97You Save: $13.86 (37%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Position Sensor

Buick Crankshaft Position Sensor Part Number: 24501417

$30.17 MSRP: $49.97You Save: $19.80 (40%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Crankshaft Sensor; Position Sensor

Buick Crankshaft Position Sensor Part Number: 25535481

$20.46 MSRP: $32.02You Save: $11.56 (37%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Position Sensor; Sensor

Buick Knock Sensor Part Number: 55503494

$14.80 MSRP: $26.40You Save: $11.60 (44%)Product Specifications- Other Name: Sensor, Distributor (Also Knock Sensor)

- Replaced by: 12737536

Buick Crankshaft Position Sensor Part Number: 25525666

$13.11 MSRP: $18.75You Save: $5.64 (31%)Product Specifications- Other Name: Component Parts Serviced

Buick Crankshaft Position Sensor Part Number: 12537111

$42.91 MSRP: $80.07You Save: $37.16 (47%)Product Specifications- Other Name: Sensor, Distributor (Also Knock Sensor); Camshaft Position Sensor; Crankshaft Sensor; Position Sensor; Sensor

Buick Knock Sensor Part Number: 10456287

Product Specifications- Other Name: Sensor, Distributor (Also Knock Sensor); Control Module; ESC Sensor; Sensor

- Replaces: 10456017

Buick Knock Sensor Part Number: 10456019

Product Specifications- Other Name: Sensor, Distributor (Also Knock Sensor)

Buick Knock Sensor Part Number: 10456208

$62.55 MSRP: $111.70You Save: $49.15 (44%)Product Specifications- Other Name: Sensor, Distributor (Also Knock Sensor)

Buick Position Sensor Part Number: 12537109

Product Specifications- Other Name: Sensor Assembly-Crankshaft Position; Crankshaft Position Sensor; Sensor; Sensor, Distributor (Also Knock Sensor)

Buick Crankshaft Position Sensor Part Number: 12567649

Product Specifications- Other Name: Sensor, Distributor (Also Knock Sensor); Camshaft Position Sensor; Crankshaft Sensor; Camshaft Sensor

- Replaces: 24506494, 24508213, 24506905

Buick Crankshaft Position Sensor Part Number: 10226176

Product Specifications- Other Name: Sensor Assembly-Crankshaft Position; Crankshaft Sensor; Sensor, Distributor (Also Knock Sensor)

- Replaces: 24504569

| Page 1 of 2 |Next >

1-20 of 37 Results

Buick Crankshaft Position Sensor

Want to cut long-term maintenance and repair costs? Choose OEM Crankshaft Position Sensor. Those parts deliver top durability you can trust. On our site, you'll find a huge catalog of genuine Buick parts. Prices are unbeatable, so you can keep more in your pocket. Every OEM Buick Crankshaft Position Sensor includes a manufacturer's warranty. You can also get an easy return policy that keeps buying risk free. Fast delivery, get your car on the road quickly. It's simple to search, compare, and order. Stop guessing about quality or fit. Order today and save with parts that last.

Buick Crankshaft Position Sensor Parts Questions & Experts Answers

- Q: How to replace the Crankshaft Position Sensor on Buick LaCrosse?A:Begin the Crankshaft Position Sensor replacement by turning off the ignition then supporting the lifted vehicle. We need to relocate the wiring harness heat shield to access before we can unplug the crankshaft position (CKP) electrical connector . First remove the crankshaft sensor bolt then extract the crankshaft sensor from its location. Position the new crankshaft position sensor then install the crankshaft sensor bolt with a torque setting of 10 N.m (89 lb in). Lower the vehicle after you fasten the wiring harness heat shield to the oil level indicator tube then reconnect the CKP electrical connector.

- Q: How to service and repair the Crankshaft Position Sensor on Buick LeSabre?A:Service procedures for Crankshaft Position Sensor repair should begin with using a scan tool to monitor the powertrain control module (PCM) for dtcs except p1336; refer to the diagnostic trouble code list when other dtcs exist. Start the learn procedure for crankshaft position (CKP) variation through a scan tool to monitor engine fuel cut-off situations. Follow the scan tool's instructions: first secure the drive wheels then engage the parking brake and cycle ignition from off to on before holding down the Brake Pedal to start the engine while idling it in park (A/T) or neutral (M/T) mode with a/c off. During the procedure the scan tool monitors three functions: ckp sensor activity alongside cmp sensor activity while tracking engine coolant temperature (ECT) values. You should let the engine idle until the engine coolant temperature sensor shows it has reached its target range. Follow the scan tool instructions to enable ckp system variation learning during which time unlock the throttle pedal instantly when engine deceleration occurs to let engine control return to the driver. Advance engine speed while monitoring rpm until fuel cut-off occurs then release the throttle. The scan tool indicates "learn status: learned this ignition" in its display. Learned this ignition." no additional dtcs exist when the initialization message fails to display so check to determine if there are any engine-related symptoms. A dtc present indicates to check the dtc list for relevant information. Complete the learn procedure by shutting off the ignition after a period of 30 seconds for successful completion.

- Q: How to Perform the Crankshaft Position Sensor System Variation Learn Procedure and What Conditions Must Be Met on Buick Regal?A:The Crankshaft position (CKP) system variation compensating values reside in pcm non-volatile memory following a learn procedure which must run after setting dtc p1336 or when the pcm or Crankshaft position sensor and engine and Crankshaft and Crankshaft Harmonic Balancer are replaced. A safety precaution requires blocking drive wheels while applying the parking brake before beginning the procedure. Relax throttle pressure when the engine hits its 5,150 rpm second fuel cut-off point while the motor uses natural idle descending. Following a completed learn procedure the pcm will hand control of the engine back to the operator. The engine coolant temperature must exceed 70°c (158°F) before starting the learn procedure because the scan tool function becomes disabled for lower temperatures. During the learn function pcm disables operation when powertrain dtcs besides p1336 appear or detects problems with the camshaft position signal circuit, 3x reference circuit, or 18x reference circuit. Apply the parking brake and disable the driver wheels along with checking that the hood is secure before starting the learn procedure. After starting the engine let the coolant temperature rise to at least 70°c (158°F) before shutting down the ignition. Begin the Crankshaft position system variation learn procedure with your scanner test tool enabled while starting the vehicle using normal braking routines that maintain pressure on the Brake Pedal and keeping the transaxle in the park position. Push the accelerator pedal to achieve the first ckp system variation learn fuel cut-off point then let go of the pedal when the second fuel cut-off happens. The learning of compensating values occurs when rpm reaches its initial idle position. Check for dtc p1336 after finishing the scan. Toward completion of this task inspect dtc p1336 for a result of 'passed.' the learn process should be repeated because other dtcs cleared out during diagnosis and p1336 remained the only dtc.