ChevyParts

My Garage

My Account

Cart

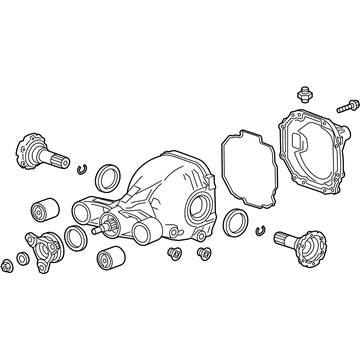

OEM Cadillac CTS Differential

Front Differential- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

26 Differentials found

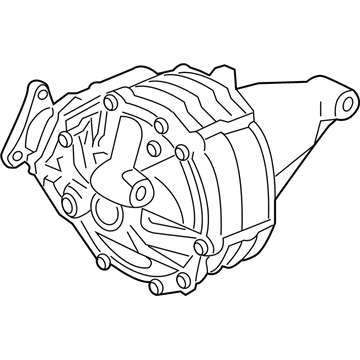

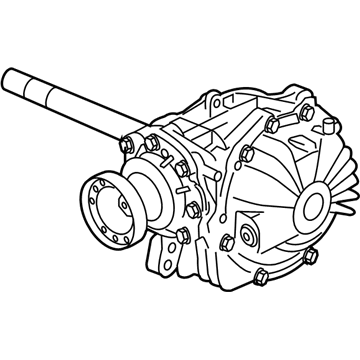

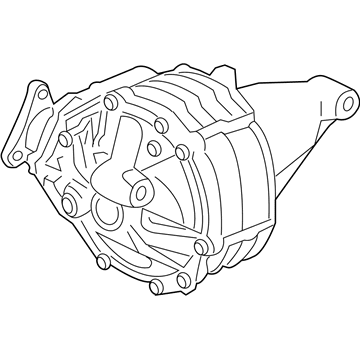

Cadillac CTS Differential Assembly Part Number: 84110755

$2792.90 MSRP: $3610.72You Save: $817.82 (23%)Cadillac CTS Differential Assembly Part Number: 84173769

$3339.31 MSRP: $4297.70You Save: $958.39 (23%)Ships in 1-3 Business DaysCadillac CTS Differential Assembly Part Number: 84173768

$2228.88 MSRP: $2868.57You Save: $639.69 (23%)Ships in 1-3 Business DaysCadillac CTS Differential Assembly Part Number: 84110751

$2702.71 MSRP: $3393.54You Save: $690.83 (21%)

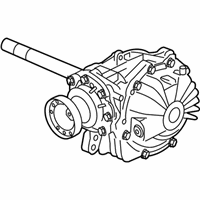

Cadillac CTS Carrier Part Number: 25873497

Cadillac CTS Carrier Part Number: 25873500

Cadillac CTS Differential Carrier Part Number: 25978161

Cadillac CTS Differential Carrier Part Number: 20931063

Cadillac CTS Differential Carrier Part Number: 25873499

Cadillac CTS Differential Carrier Part Number: 25978162

Cadillac CTS Differential Carrier Part Number: 20953704

Cadillac CTS Differential Carrier Part Number: 25979061

Cadillac CTS Differential Carrier Part Number: 25873498

Cadillac CTS Differential Carrier Part Number: 25979054

Cadillac CTS Differential Carrier Part Number: 25979053

Cadillac CTS Differential Carrier Part Number: 25979062

Cadillac CTS Differential Assembly Part Number: 84110752

Cadillac CTS Differential Carrier Part Number: 20931073

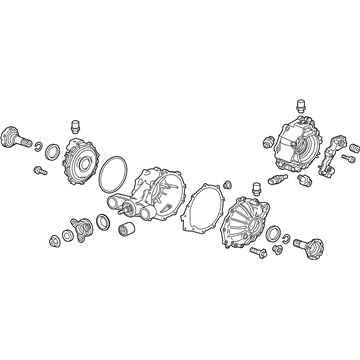

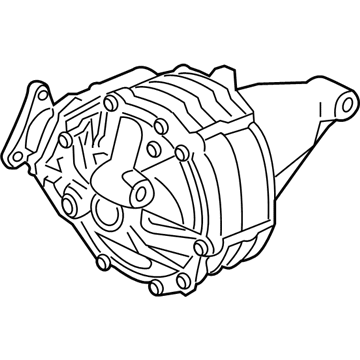

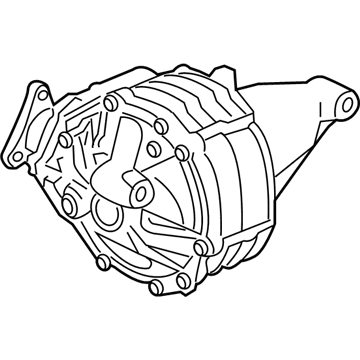

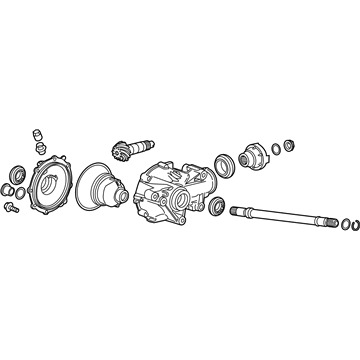

Cadillac CTS Carrier Assembly, Front Part Number: 23317167

$596.38 MSRP: $942.60You Save: $346.22 (37%)Cadillac CTS Carrier Assembly, Front Part Number: 25978167

$2141.91 MSRP: $2756.64You Save: $614.73 (23%)

| Page 1 of 2 |Next >

1-20 of 26 Results

Cadillac CTS Differential

Want to cut long-term maintenance and repair costs? Choose OEM Differential. Those parts deliver top durability you can trust. On our site, you'll find a huge catalog of genuine Cadillac CTS parts. Prices are unbeatable, so you can keep more in your pocket. Every OEM Cadillac CTS Differential includes a manufacturer's warranty. You can also get an easy return policy that keeps buying risk free. Fast delivery, get your car on the road quickly. It's simple to search, compare, and order. Stop guessing about quality or fit. Order today and save with parts that last.

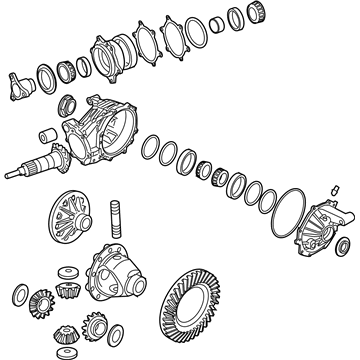

This is made possible by the Cadillac CTS differential which is used to split the power output and deliver this to the drive wheels and therefore there will be a variation of the wheels in as much as they will be performing a turn. It is also vital in the provision of the grip as well as proper road handling. In the Cadillac CTS the distribution of the differentials is also diverse based on the type, including the open and the limited-slip differential (LSD). Another possible reason of gaining such amount of traction is that the Cadillac CTS is equipped with the open differential that gives an equal torque distribution to the wheels which can be crucial during the regular drive. On the other hand, the LSD, fitted in the Cadillac CTS, controls torque splitting and distributes power to the wheels depending on the amount of grip and this is beneficial in winter or while racing. These differential types have been applied in Cadillac CTS in the past years as a way of improving the drivability and the performance of the car. The open differential is uncomplicated but tricky in areas where the wheels have less traction as seen in slippery terrains. The LSD, however, addresses this by preventing more torque to the wheel which has a better grip and hence improving handling at higher speed or in bad weather. Differentials in Cadillac CTS come in different types and each of it has certain applications to fit the vehicle's need in terms of driving.

Cadillac CTS Differential Parts Questions & Experts Answers

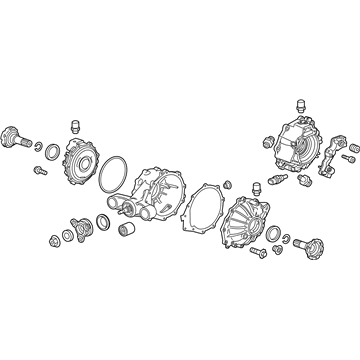

- Q: What steps should be taken to clean and inspect the differential case, ring gear, pinion flange, and bearing components on Cadillac CTS?A:Clean the differential case in the solvent and note chips, cracks, injury to bolt holes, rough wear, grooves, scoring, damaged side bearing flanges, heat discoloration, badly-worn differential pin bores. Also clean the ring gear in solvent and check for any damage to the threaded holes and any abnormal wear or heat discoloration of the gear teeth. Use the pinion flange to clean it with solvent, and make inspections for wear, pitting, and splines and grooves or pitting on sealing surface. Examine the bearing rollers and races for pitting, scoring, grooving, extreme wear, and other defect, with heat discoloration that varies from pale yellow to deep blue, which imply overload or insufficient oil; Any heated colored bearings or races must be changed. Further, check for bent bearing cage, and inspect for damaged bearing cage.