ChevyParts

My Garage

My Account

Cart

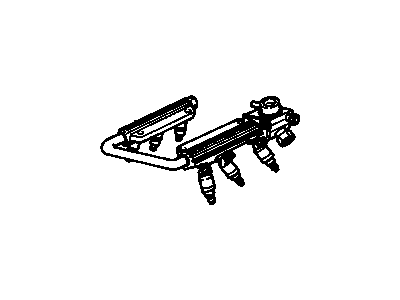

OEM Chevrolet Cavalier Fuel Rail

Engine Fuel Rail- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

11 Fuel Rails found

Chevrolet Cavalier Fuel Rail Part Number: 17110851

$211.64 MSRP: $379.62You Save: $167.98 (45%)Ships in 1-3 Business DaysChevrolet Cavalier Fuel Rail Part Number: 17113318

$37.16 MSRP: $319.94You Save: $282.78 (89%)Ships in 1-2 Business Days

Chevrolet Cavalier Fuel Rail Part Number: 12574331

Chevrolet Cavalier Fuel Rail Part Number: 17113579

Chevrolet Cavalier Fuel Rail Part Number: 17111794

Chevrolet Cavalier Fuel Rail Part Number: 17111781

Chevrolet Cavalier Fuel Rail Part Number: 17113655

Chevrolet Cavalier Fuel Rail Part Number: 17113394

Chevrolet Cavalier Fuel Rail Part Number: 17113236

Chevrolet Cavalier Fuel Rail Part Number: 17113235

Chevrolet Cavalier Fuel Rail Part Number: 12574291

Chevrolet Cavalier Fuel Rail

Want to cut long-term maintenance and repair costs? Choose OEM Fuel Rail. Those parts deliver top durability you can trust. On our site, you'll find a huge catalog of genuine Chevrolet Cavalier parts. Prices are unbeatable, so you can keep more in your pocket. Every OEM Chevrolet Cavalier Fuel Rail includes a manufacturer's warranty. You can also get an easy return policy that keeps buying risk free. Fast delivery, get your car on the road quickly. It's simple to search, compare, and order. Stop guessing about quality or fit. Order today and save with parts that last.

Chevrolet Cavalier Fuel Rail Parts Questions & Experts Answers

- Q: How to service the fuel rail on Chevrolet Cavalier?A:Service procedures on the Fuel Rail begin by pressurizing the fuel system before disconnecting the Battery Cable. You must remove both the air cleaner outlet resonator along with its vented mounting bracket. The electrical connectors connecting Fuel Injectors require disconnecting through a procedure of pressing wire clip sections while extracting connectors from Fuel Injector positions. The first process involves removing the three components including the fuel feed inlet pipe quick connect, fuel return pipe from the Fuel Pressure Regulator and the Fuel Rail attaching bolts in order to extract the Fuel Rail assembly from the Cylinder Head. Before installation apply clean engine oil to the Fuel Injector o-rings then put the Fuel Rail inside the Cylinder Head. Fasten the Fuel Rail attaching bolts at 24 n.m (18 lbs ft) torque diameter. Connect the fuel feed inlet pipe quick connect to its port and the fuel return pipe to the Fuel Pressure Regulator while tightening its attaching nut to 30 n.m (22 lb ft). Secure the Fuel Rail bracket by tightening its nut to 10 n.m and nut to 25 n.m and bolt to 25 n.m. To complete the procedure reconnect the negative Battery Cable while checking for fuel leaks through an observation period consisting of two seconds at on position, followed by ten seconds at off position then two seconds at on position to verify any leak occurrence.