ChevyParts

My Garage

My Account

Cart

OEM Chevrolet Express 2500 Harmonic Balancer

Engine Harmonic Balancer- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

13 Harmonic Balancers found

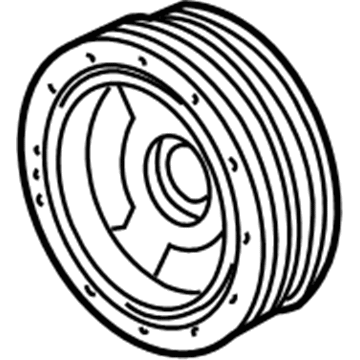

Chevrolet Express 2500 Vibration Damper Part Number: 19300488

$115.88 MSRP: $199.00You Save: $83.12 (42%)Ships in 1-2 Business Days

Chevrolet Express 2500 Crankshaft Pulley Part Number: 12684590

$85.02 MSRP: $144.73You Save: $59.71 (42%)Ships in 1-2 Business Days

Chevrolet Express 2500 Vibration Damper Part Number: 10243271

$91.05 MSRP: $156.37You Save: $65.32 (42%)Ships in 1-2 Business Days

Chevrolet Express 2500 Vibration Damper Part Number: 10224885

$65.09 MSRP: $106.52You Save: $41.43 (39%)Chevrolet Express 2500 Vibration Damper Part Number: 19432547

$321.86 MSRP: $506.42You Save: $184.56 (37%)Chevrolet Express 2500 Vibration Damper Part Number: 97374383

$809.93 MSRP: $1280.12You Save: $470.19 (37%)Ships in 1-3 Business DaysChevrolet Express 2500 Vibration Damper Part Number: 19417972

$409.58 MSRP: $650.30You Save: $240.72 (38%)Ships in 1-2 Business DaysChevrolet Express 2500 Crankshaft Pulley Part Number: 12680364

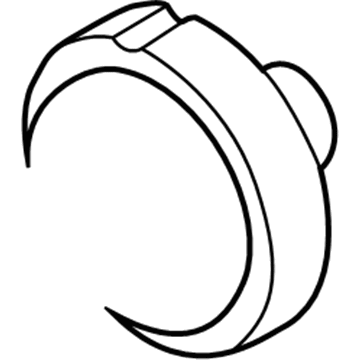

$79.01 MSRP: $134.48You Save: $55.47 (42%)Chevrolet Express 2500 Balance Shaft Part Number: 12653449

$137.66 MSRP: $216.60You Save: $78.94 (37%)Ships in 1-3 Business DaysChevrolet Express 2500 Vibration Damper Part Number: 12625430

$72.52 MSRP: $113.58You Save: $41.06 (37%)Ships in 1-3 Business DaysChevrolet Express 2500 Vibration Damper Part Number: 10243272

$207.93 MSRP: $357.10You Save: $149.17 (42%)Ships in 1-2 Business Days

Chevrolet Express 2500 Vibration Damper Part Number: 12634105

Chevrolet Express 2500 Vibration Damper Part Number: 10154688

Chevrolet Express 2500 Harmonic Balancer

Want to cut long-term maintenance and repair costs? Choose OEM Harmonic Balancer. Those parts deliver top durability you can trust. On our site, you'll find a huge catalog of genuine Chevrolet Express 2500 parts. Prices are unbeatable, so you can keep more in your pocket. Every OEM Chevrolet Express 2500 Harmonic Balancer includes a manufacturer's warranty. You can also get an easy return policy that keeps buying risk free. Fast delivery, get your car on the road quickly. It's simple to search, compare, and order. Stop guessing about quality or fit. Order today and save with parts that last.

Chevrolet Express 2500 Harmonic Balancer Parts Questions & Experts Answers

- Q: How to replace the harmonic balancer on Chevrolet Express 2500?A:The first step to replace the Crankshaft balancer involves removing either the air conditioning Drive Belt with its presence or the accessory Drive Belt without it present. The replacement process starts with lower Fan Shroud removal as well as Starter motor removal. The teeth from the j 42386-a must match perfectly with the engine Flywheel. Fasten the j 42386-a with one m10-1.5 x 120 mm and one m10-1.5 x 45 mm bolt. The bolts should be tightened to 50 n.m (37 lb ft). Keep the Crankshaft balancer bolt available for reinstallation because it will find use when the replacement process begins. The j 41816 together with the j 41816-2 will be utilized to extract the Crankshaft balancer so you can clean and perform inspections. Position the Crankshaft balancer straight on the Crankshaft using the j 41665 and j 41478 tools for assistance. The j 41478 tool needs assembly with its components which include a threaded rod, nut and washer for insertion into the balancer. Use a wrench to hold the threaded rod hex end while clockwise rotations of the nut will begin the balancer onto the Crankshaft. Proceed with tool reversal while putting the large end against the balancer and maintain nut rotation to complete Crankshaft balancer installation. Use the used balancer bolt to tighten it to 330 n.m (240 lb ft) before removing it to measure the Crankshaft nose position in the balancer bore which should be 2.4-4.48 mm (0.094-0.176 in) deep. Perform the installation process again with the j 41665 only when required. The new balancer bolt for the Crankshaft needs installation while you start tightening it to 50 n.m (37 lb ft) and continue with 140-degree turn using the j 45059 tool. The repair ends with performing the Crankshaft position system variation learn procedure and reinstalling the Starter motor together with the drive belts and lower Fan Shroud according to applicable steps.