ChevyParts

My Garage

My Account

Cart

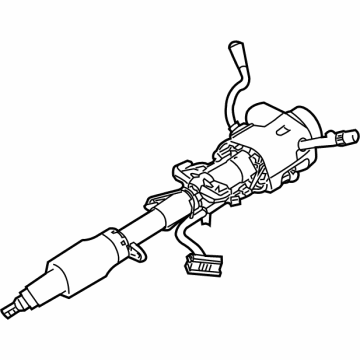

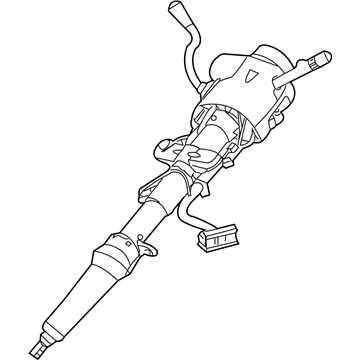

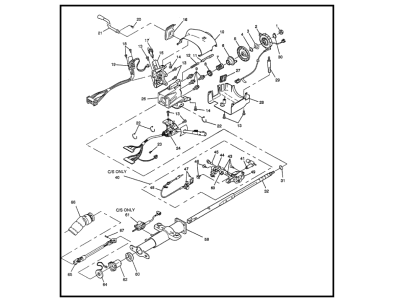

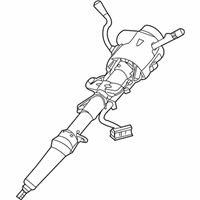

OEM Chevrolet Express 2500 Steering Column

Steering Column Tilt- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

31 Steering Columns found

Chevrolet Express 2500 Steering Column Part Number: 84879213

$479.06 MSRP: $757.18You Save: $278.12 (37%)Ships in 1-3 Business DaysChevrolet Express 2500 Steering Column Part Number: 84879212

$451.94 MSRP: $714.30You Save: $262.36 (37%)Ships in 1-3 Business DaysChevrolet Express 2500 Column Assembly Part Number: 84501610

$464.60 MSRP: $734.18You Save: $269.58 (37%)Ships in 1-3 Business DaysChevrolet Express 2500 Steering Column Part Number: 19368212

$464.60 MSRP: $734.18You Save: $269.58 (37%)Chevrolet Express 2500 Steering Column Part Number: 19300157

Chevrolet Express 2500 Steering Column Part Number: 84501609

$527.41 MSRP: $833.56You Save: $306.15 (37%)Chevrolet Express 2500 Steering Column Part Number: 19168534

Chevrolet Express 2500 Steering Column Part Number: 26093927

Chevrolet Express 2500 Jacket Part Number: 26054864

Chevrolet Express 2500 Steering Column Part Number: 26060137

Chevrolet Express 2500 Steering Column Part Number: 26061646

Chevrolet Express 2500 Steering Column Part Number: 26068555

Chevrolet Express 2500 Steering Column Part Number: 26076234

Chevrolet Express 2500 Column Assembly Part Number: 26089105

Chevrolet Express 2500 Steering Column Part Number: 26093925

Chevrolet Express 2500 Steering Column Part Number: 19300155

Chevrolet Express 2500 Steering Column Part Number: 19180635

Chevrolet Express 2500 Steering Column Part Number: 19300154

Chevrolet Express 2500 Jacket Part Number: 26046898

Chevrolet Express 2500 Steering Column Part Number: 19180611

| Page 1 of 2 |Next >

1-20 of 31 Results

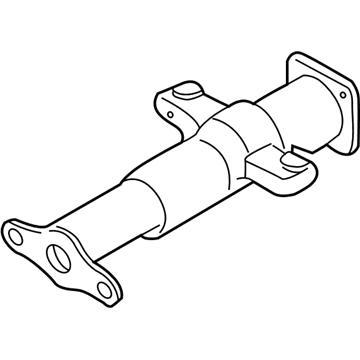

Chevrolet Express 2500 Steering Column

Want to cut long-term maintenance and repair costs? Choose OEM Steering Column. Those parts deliver top durability you can trust. On our site, you'll find a huge catalog of genuine Chevrolet Express 2500 parts. Prices are unbeatable, so you can keep more in your pocket. Every OEM Chevrolet Express 2500 Steering Column includes a manufacturer's warranty. You can also get an easy return policy that keeps buying risk free. Fast delivery, get your car on the road quickly. It's simple to search, compare, and order. Stop guessing about quality or fit. Order today and save with parts that last.

Chevrolet Express 2500 Steering Column Parts Questions & Experts Answers

- Q: What should be inspected on those involved in accidents that may have a damaged or misaligned steering column on Chevrolet Express 2500?A:Numerous accidents which trigger frame breakage alongside major body destruction and sheet metal deterioration and Steering Column or supplemental inflatable restraint deployment might damage the Steering Column alignment. Actual inspection of Steering Column bracket assembly capsules must be performed to confirm proper slot seating while testing for loose components through manual pressure and pulling movements. When the brackets show improper capsule seating but use bolts to join with the jacket assembly perform bracket replacement only. Contrarily if capsules sit improperly yet brackets weld to the jacket assembly you need to replace the entire jacket assembly. A dimension check from the bottom of the upper jacket to a specific point on the lower jacket determines jacket assembly collapse; replace the complete jacket assembly when specifications are not met. Ensure the shaft rotation starts after coil assembly removal from the Steering Column so the coil remains untethered to protect its assembly from damage. A visible inspection must be carried out on the Steering Shaft to detect broken pieces of plastic injection. If plastic injection pieces appear, the shaft needs replacement. An inspection should be performed with a dial indicator on the lower Steering Shaft end when rotating the wheel to measure runout while guaranteeing it stays under 1.60 mm (0.06 in).