ChevyParts

My Garage

My Account

Cart

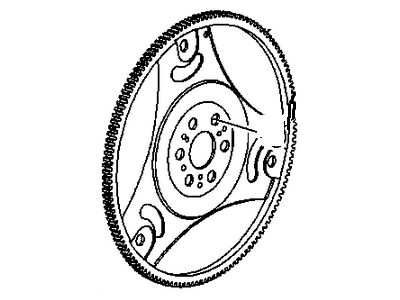

OEM Chevrolet Impala Flywheel

Clutch Flywheel- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

12 Flywheels found

Chevrolet Impala Drive Plate, Green Line Part Number: 12647333

$85.69 MSRP: $215.96You Save: $130.27 (61%)Ships in 1-3 Business Days

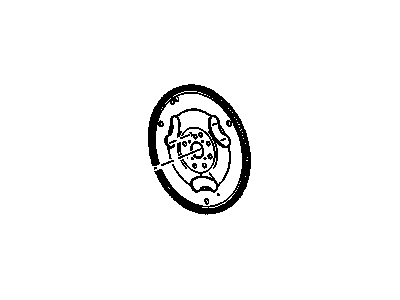

Chevrolet Impala Drive Plate Part Number: 12597026

$64.41 MSRP: $100.90You Save: $36.49 (37%)Ships in 1-2 Business DaysChevrolet Impala Drive Plate Part Number: 471529

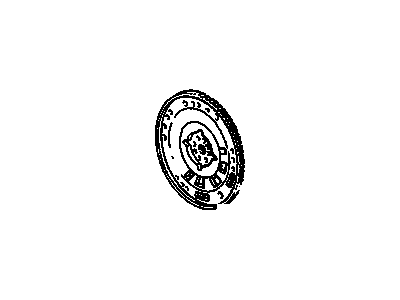

$140.65 MSRP: $166.69You Save: $26.04 (16%)Ships in 1-2 Business DaysChevrolet Impala Drive Plate Part Number: 14088765

$133.52 MSRP: $210.09You Save: $76.57 (37%)Ships in 1-2 Business DaysChevrolet Impala Drive Plate Part Number: 12686890

$64.24 MSRP: $100.66You Save: $36.42 (37%)Ships in 1-3 Business Days

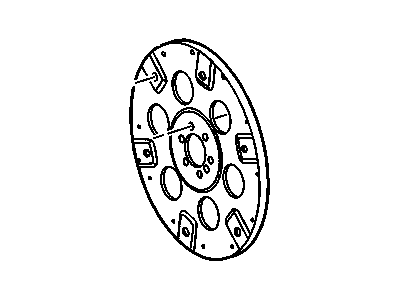

Chevrolet Impala Drive Plate Part Number: 12568922

Chevrolet Impala Drive Plate Part Number: 12609155

$52.46 MSRP: $82.19You Save: $29.73 (37%)

Chevrolet Impala Drive Plate Part Number: 12579453

$104.78 MSRP: $164.11You Save: $59.33 (37%)Chevrolet Impala Drive Plate Part Number: 471598

$110.60 MSRP: $131.66You Save: $21.06 (16%)Chevrolet Impala Drive Plate Part Number: 25512348

Chevrolet Impala Drive Plate Part Number: 22500808

Chevrolet Impala Drive Plate Part Number: 12609154

Chevrolet Impala Flywheel

Want to cut long-term maintenance and repair costs? Choose OEM Flywheel. Those parts deliver top durability you can trust. On our site, you'll find a huge catalog of genuine Chevrolet Impala parts. Prices are unbeatable, so you can keep more in your pocket. Every OEM Chevrolet Impala Flywheel includes a manufacturer's warranty. You can also get an easy return policy that keeps buying risk free. Fast delivery, get your car on the road quickly. It's simple to search, compare, and order. Stop guessing about quality or fit. Order today and save with parts that last.

Chevrolet Impala Flywheel Parts Questions & Experts Answers

- Q: How to replace the engine flywheel on Chevrolet Impala?A:Before starting engine Flywheel replacement work you need to remove the transaxle. The Flywheel holder (J 37096) should be used to stop Flywheel movement before instructing to loosen the 8 engine Flywheel bolts. Keep one bolt intact at the top position of Crankshaft rotation before you proceed with removing seven other bolts. Securely hold the engine Flywheel before removing the final bolt which requires special attention to prevent the Flywheel from falling. Install the new engine Flywheel after removing the old one through the use of Flywheel holder (J 37096) to securely manage wheel motion. Fasten the new engine Flywheel bolts while torquing them to 15 nm (11 ft. Lbs.). Employ the torque angle meter (J 45059) to apply an extra fifty-degree rotation to the bolts which keeps the Crankshaft end play all in one direction for this examination. Engine Flywheel runout measurement requires placing a dial indicator on the engine block to evaluate the runout at three attaching bosses; the replacement of the engine Flywheel is needed when runout exceeds specifications and adjustments cannot solve the issue. Finally, install the transaxle.