ChevyParts

My Garage

My Account

Cart

OEM Chevrolet Silverado 1500 Distributor

Ignition Distributor- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

1 Distributor found

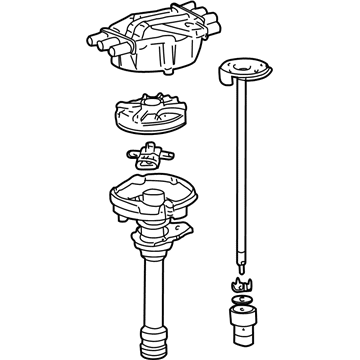

Chevrolet Silverado 1500 Distributor Assembly Part Number: 12598210

Chevrolet Silverado 1500 Distributor

Want to cut long-term maintenance and repair costs? Choose OEM Distributor. Those parts deliver top durability you can trust. On our site, you'll find a huge catalog of genuine Chevrolet Silverado 1500 parts. Prices are unbeatable, so you can keep more in your pocket. Every OEM Chevrolet Silverado 1500 Distributor includes a manufacturer's warranty. You can also get an easy return policy that keeps buying risk free. Fast delivery, get your car on the road quickly. It's simple to search, compare, and order. Stop guessing about quality or fit. Order today and save with parts that last.

Chevrolet Silverado 1500 Distributor Parts Questions & Experts Answers

- Q: How to overhaul the distributor on Chevrolet Silverado 1500?A:Proper Distributor overhaul starts with equipment removal followed by marking each hole on the driven gear and Distributor shaft and rotor for later assembly. Position the white paint mark on the Distributor's bottom stem against the pre-drilled indent hole found at the gear's lower end for accurate v6 engine rotor orientation. If not, replace the Distributor. Separate the rotor screws from the rotor by keeping track of both rotor screw hole locations and rotor locator pin hole positions. Follow the cmp sensor alignment with the vane wheel square-cut hole before eliminating the cmp sensor screws and discarding both the cmp sensor and screws. Check the dimple underneath the roll pin hole on one side of the gear to identify correct installation order when putting parts together. A v-block fixture supports the Distributor drive gear while a suitable punch drives out the roll pin to remove all components including the driven gear and round washer and tang washer and shim washer and oil seal. When assembling the system place the square-cut hole of the cmp sensor vane wheel correctly then screw in the cmp sensor using new screws tightened to 2.2 n.m (19 lb in). Mark the appropriate rotor mounting locations. Drive the Distributor rotor into position based on index marks and torque rotor screws to 1.9 n.m (17 lb in). Depositing the shim washer under the Distributor shaft should be followed by inserting the tang washer and afterward adding the round washer. To install the driven gear follow index marks while aligning the rotor segment according to v6 engine specifications so that the white paint mark on the Distributor bottom stem will match the pre-drilled indent hole on the bottom of the gear. The driven gear installation must be precise because incorrect positioning will shift the dimple 180 degrees against the rotor segment. Before you start fix the Distributor drive gear inside a v-block mount then use a proper punch to insert the roll pin while hitting it with a hammer until it takes its final position under the Distributor base mounting flange before final installation.