ChevyParts

My Garage

My Account

Cart

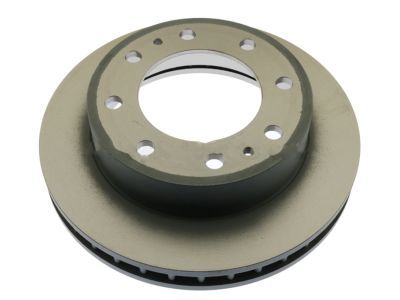

OEM Chevrolet Silverado 2500 Brake Disc

Disc Rotor- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

5 Brake Discs found

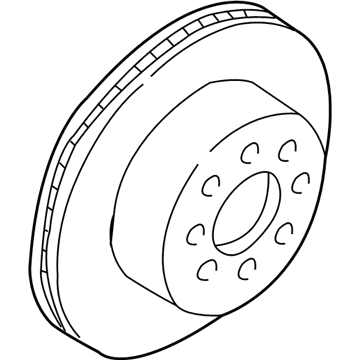

Chevrolet Silverado 2500 Brake Rotor Part Number: 25757802

$143.40 MSRP: $274.21You Save: $130.81 (48%)Ships in 1-2 Business Days

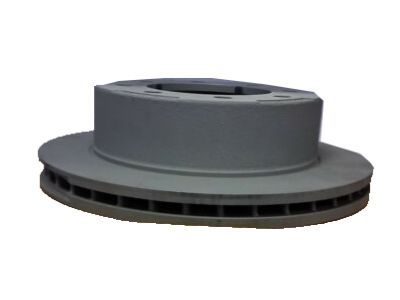

Chevrolet Silverado 2500 Rotor Part Number: 15712803

$170.40 MSRP: $325.78You Save: $155.38 (48%)Ships in 1-2 Business Days

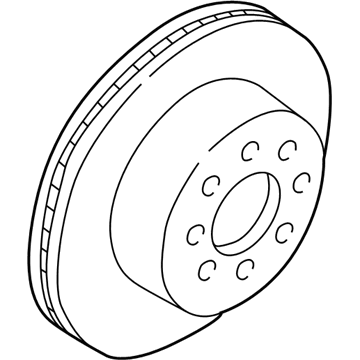

Chevrolet Silverado 2500 Rotor Part Number: 15712801

$96.36 MSRP: $180.93You Save: $84.57 (47%)

Chevrolet Silverado 2500 Rotor, Front Part Number: 15942198

$192.78 MSRP: $374.16You Save: $181.38 (49%)Ships in 1-2 Business Days

Chevrolet Silverado 2500 Rotor, Front Part Number: 15942195

$154.61 MSRP: $302.70You Save: $148.09 (49%)Ships in 1-2 Business Days

Chevrolet Silverado 2500 Brake Disc

Want to cut long-term maintenance and repair costs? Choose OEM Brake Disc. Those parts deliver top durability you can trust. On our site, you'll find a huge catalog of genuine Chevrolet Silverado 2500 parts. Prices are unbeatable, so you can keep more in your pocket. Every OEM Chevrolet Silverado 2500 Brake Disc includes a manufacturer's warranty. You can also get an easy return policy that keeps buying risk free. Fast delivery, get your car on the road quickly. It's simple to search, compare, and order. Stop guessing about quality or fit. Order today and save with parts that last.

Chevrolet Silverado 2500 Brake Disc Parts Questions & Experts Answers

- Q: How can the assembled lateral runout (LRO) of the front brake disc be corrected on Chevrolet Silverado 2500?A:To adjust the collected lateral runout (LRO) of the Brake Disc, initially ensure that an examination is done on the Brake Disc thickness, as whenever exceeded, brake pulsation is ensured. Start the measuring process by removing the conical Brake Disc washers (J 45101-100) and the lug nuts that were inserted at the time of the lro measurement. Check the mating surface of hub/axle flange and Brake Disc for any foreign particles or debris. Next, index the Brake Disc in another orientation to the resultant hub/axle flange, hold it in position and install one (1) conical Brake Disc washer (J 45101-100) and one (1) lug nut to the upper-most wheel stud, tightening the lug nut firmly by hand. Continue to retain the disc and install the balance conical Brake Disc washers (J 45101-100) and lug nuts to the brake studs with moderate hand tightening in a star shape. With the torque-limiting socket set (J 39544-KIT), torque the lug nuts in a star fashion to specification to correctly fasten the disc. Yes, take the lro that has been assembled and measure it and compare to the original prior to cleaning while keeping in mind that we have to take repeated measurements and hold it at a perpendicular alignment to obtain accurate reading. If measurement is within specifications, install the brake caliper and operate the brake pedal several times to lock the disc before installing the conical Brake Disc washers (J 45101-100) and lug nuts. When the measurement is outside specification, repeat the indexing and tightening until the best assembled lro measurement is achieved, and matchmark the final position of the disc to the wheel studs, if the orientation is differing from the original.