ChevyParts

My Garage

My Account

Cart

OEM Chevrolet Silverado 3500 Oil Pan

Oil Drain Pan- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

4 Oil Pans found

Chevrolet Silverado 3500 Oil Pan Part Number: 98073535

$245.87 MSRP: $333.75You Save: $87.88 (27%)Chevrolet Silverado 3500 Oil Pan Part Number: 12579273

$313.43 MSRP: $538.29You Save: $224.86 (42%)Ships in 1-2 Business Days

Chevrolet Silverado 3500 Oil Pan Part Number: 97329702

$811.00 MSRP: $1281.81You Save: $470.81 (37%)Chevrolet Silverado 3500 Oil Pan Part Number: 12574833

Chevrolet Silverado 3500 Oil Pan

Want to cut long-term maintenance and repair costs? Choose OEM Oil Pan. Those parts deliver top durability you can trust. On our site, you'll find a huge catalog of genuine Chevrolet Silverado 3500 parts. Prices are unbeatable, so you can keep more in your pocket. Every OEM Chevrolet Silverado 3500 Oil Pan includes a manufacturer's warranty. You can also get an easy return policy that keeps buying risk free. Fast delivery, get your car on the road quickly. It's simple to search, compare, and order. Stop guessing about quality or fit. Order today and save with parts that last.

Chevrolet Silverado 3500 Oil Pan Parts Questions & Experts Answers

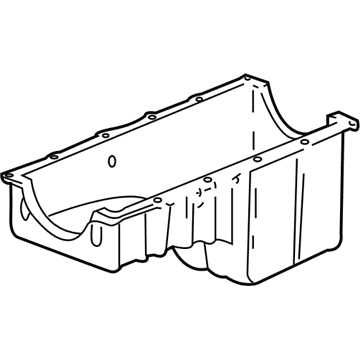

- Q: How to replace the oil pan on Chevrolet Silverado 3500?A:The first step for Oil Pan replacement begins by removing inner axle housing nuts and washers that secure the bracket when a vehicle has four wheel drive (4WD). Then you should use a suitable jack to support the front drive axle. You must first lower the front drive axle after removing the differential carrier upper and lower mounting bolts and nuts. Then remove the transmission cover bolt. Ensure to remove the Oil Pan skid plate after unbolted hardware then remove the crossbar component with its associated bolts. Pump out engine oil before extracting the engine Oil Filter before securely reassembling drain plug and Oil Filter together. The right side transmission bolt plus stud and left side bottom bolt need removal for vehicles with 4l60-e automatic transmission. Drivers who have the 4l80-e automatic transmission should start by taking out the transmission converter cover bolts. First disconnect the oil level sensor electrical connector before you remove the battery cable channel bolt and slide the channel pin out from the Oil Pan tab. Detach the engine wiring harness clip and positive battery cable clip from the positive battery cable clip then remove the engine oil cooler lines along with the positive battery cable clip bolt and clip. Next remove the Oil Pan bolts and the Oil Pan itself. Remove all the Oil Pan bolts while maintaining passage cleanliness from foreign objects. Drill out any rivets which lock the Oil Pan Gasket before completely removing it with its rivets. Check the engine Oil Pan for required cleaning and inspection. To install the parts you must apply a 5 mm (0.20 inch) bead of gm p/n 12378190 sealant or its equivalent on the tabs of the front and rear cover gaskets which extend into the Oil Pan surface. Position the oil gallery passages of the Oil Pan against their counterparts in the engine block with the new gasket. Install the Oil Pan with gasket and bolts onto the engine block tightening the Oil Pan bolts after achieving initial resistance then stop. For vehicles with 4l80-e automatic transmission secure converter cover bolts initially until they achieve a tight fit but for vehicles with 4l60-e automatic transmission tighten the right side transmission bolt and stud until they are snug. Tighten the bolts on the left bottom side until they are snuggly fit before applying torque sequences beginning at 25 nm (18 ft. Lbs.) for Oil Pan and Oil Pan-to-Oil Pan front cover bolts and continuing with 12 nm (106 inch lbs.) on the Oil Pan-to-rear cover bolts and finishing at 50 nm (37 ft. Lbs.) for the bellhousing, converter cover, and transmission bolts/stud. Furnish the Oil Pan with the positive battery cable clip and bolt before tightening the bolt to 9 nm (80 inch lbs.). Afterward, attach the engine oil cooler lines along with the engine wiring harness clip and positive battery cable clip to the positive battery cable clip. Insert the channel pin into the Oil Pan tab while installing the battery cable channel bolt at 12 nm (106 inch lbs.) torque. Then connect the oil level sensor electrical connector and secure the transmission cover and bolt at 12 nm (106 inch lbs.). Reposition the crossbar before installing its bolts at 100 nm (74 ft. Lbs.) torque setting. If equipped with the Oil Pan skid plate then install its bolts at 20 nm (15 ft. Lbs.). Have a helper raise the front axle into position so you can install the differential carrier upper mounting bolt and nut loosely before tightening both the differential carrier lower mounting bolt and nut to 100 nm (75 ft. Lbs.). Proceed to install the inner axle housing washers and nuts to the bracket while tightening them to 100 nm (75 ft. Lbs.) first install new engine oil and an Oil Filter then put the jack aside before reinstalling the front drive axle.