ChevyParts

My Garage

My Account

Cart

OEM Chevrolet Suburban 2500 Torsion Bar

Suspension Torsion Bar- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

10 Torsion Bars found

Chevrolet Suburban 2500 Torsion Bar, Front Driver Side Part Number: 19330060

$312.71 MSRP: $492.03You Save: $179.32 (37%)

Chevrolet Suburban 2500 Torsion Bar, Front Passenger Side Part Number: 19330059

$312.71 MSRP: $492.03You Save: $179.32 (37%)Ships in 1-3 Business Days

Chevrolet Suburban 2500 Torsion Bar, Front Driver Side Part Number: 19330058

$312.77 MSRP: $492.12You Save: $179.35 (37%)

Chevrolet Suburban 2500 Torsion Bar, Front Passenger Side Part Number: 19330057

$312.77 MSRP: $492.12You Save: $179.35 (37%)

Chevrolet Suburban 2500 Torsion Bar, Front Part Number: 15048312

$257.64 MSRP: $405.40You Save: $147.76 (37%)Ships in 1-3 Business Days

Chevrolet Suburban 2500 Torsion Bar, Front Passenger Side Part Number: 19332946

$257.82 MSRP: $405.67You Save: $147.85 (37%)

Chevrolet Suburban 2500 Torsion Bar, Front Driver Side Part Number: 19332945

$257.82 MSRP: $405.67You Save: $147.85 (37%)Chevrolet Suburban 2500 Torsion Bar, Front Part Number: 19332931

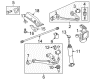

Chevrolet Suburban 2500 Torsion Bar

Want to cut long-term maintenance and repair costs? Choose OEM Torsion Bar. Those parts deliver top durability you can trust. On our site, you'll find a huge catalog of genuine Chevrolet Suburban 2500 parts. Prices are unbeatable, so you can keep more in your pocket. Every OEM Chevrolet Suburban 2500 Torsion Bar includes a manufacturer's warranty. You can also get an easy return policy that keeps buying risk free. Fast delivery, get your car on the road quickly. It's simple to search, compare, and order. Stop guessing about quality or fit. Order today and save with parts that last.

Chevrolet Suburban 2500 Torsion Bar Parts Questions & Experts Answers

- Q: How to replace the torsion bar on Chevrolet Suburban 2500?A:Vehicle installation requires support at a raised position before starting the Torsion Bar replacement process. Install the Torsion Bar unloading/loading tool (J36202) between the adjustment arm and crossmember while applying tension to the adjustment arm until the adjustment bolt and adjuster nut become tension-free. Record a reference mark on the adjustment bolt along with the number of turns needed to remove it. You must remove both the adjustment bolt and adjuster nut from vehicles that use mn8, mt1, and mw3 along with the other nuts and bolts. Uninstall the j36202 tool andproceed to move the Torsion Bar ahead to pass the adjustment arm with hand support on the bar. The installation requires separation of the crossmember bolts from both Torsion Bar weld nuts and upper link mounting nuts and bolts. Make note of the Torsion Bar configurations before you take the torsion bars off your vehicle. The installation process begins by placing torsion bars on the lower Control Arm while you attach the Torsion Bar crossmember. Secure the Torsion Bar crossmember bolts to their weld nuts using torque at 95 nm (70 ft. Lbs.). Fasten the upper link mounting nuts along with their bolts by tightening the nuts to 95 nm (70 ft. Lbs.). Support the adjustment arm while pushing the Torsion Bar backwards until it locks into position before reinstalling the j36202 to the adjustment arm and crossmember. Release adjustment arm tension when torqueing the bolt by a number of turns equal to the original removal. Proceed by installing both the adjustment bolt and adjuster nut alongside removal of j36202 from cars fitted with mn8, mt1, mw3 and lowering the vehicle after stand removal. Use a ruler to measure the z height before adjusting the adjustment bolt + to increase z height and - to decrease it.