ChevyParts

My Garage

My Account

Cart

OEM Chevrolet Tahoe Fuel Rail

Engine Fuel Rail- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

25 Fuel Rails found

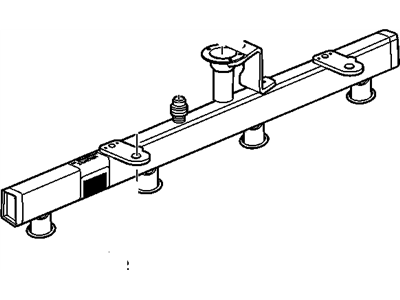

Chevrolet Tahoe Fuel Rail Part Number: 97361353

$336.68 MSRP: $683.83You Save: $347.15 (51%)

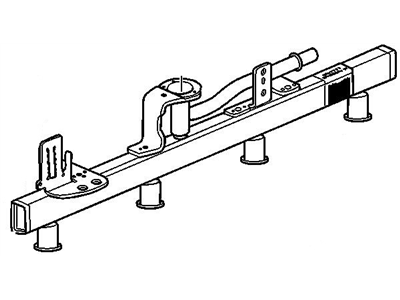

Chevrolet Tahoe Fuel Rail Part Number: 97361352

$351.85 MSRP: $714.61You Save: $362.76 (51%)

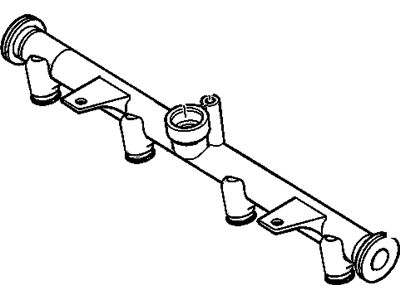

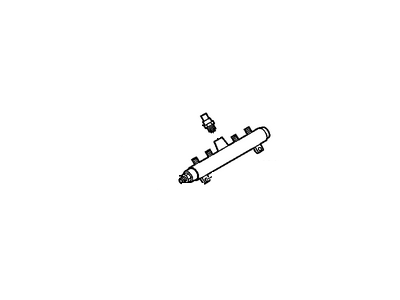

Chevrolet Tahoe Fuel Rail Part Number: 12602113

$114.68 MSRP: $232.93You Save: $118.25 (51%)Ships in 1-2 Business Days

Chevrolet Tahoe Fuel Rail Part Number: 17113695

$104.95 MSRP: $327.45You Save: $222.50 (68%)Ships in 1-2 Business DaysChevrolet Tahoe Fuel Rail Part Number: 12621668

$198.77 MSRP: $359.76You Save: $160.99 (45%)Ships in 1-2 Business DaysChevrolet Tahoe Fuel Rail Part Number: 89018110

$188.56 MSRP: $341.28You Save: $152.72 (45%)Ships in 1-2 Business DaysChevrolet Tahoe Fuel Rail Part Number: 12729464

$117.50 MSRP: $238.66You Save: $121.16 (51%)Ships in 1-2 Business DaysChevrolet Tahoe Fuel Rail Part Number: 55505909

$198.35 MSRP: $355.78You Save: $157.43 (45%)Ships in 1-3 Business DaysChevrolet Tahoe Fuel Rail Part Number: 12729466

$117.50 MSRP: $238.66You Save: $121.16 (51%)

Chevrolet Tahoe Fuel Rail Part Number: 97303659

Chevrolet Tahoe Fuel Rail Part Number: 97208075

Chevrolet Tahoe Fuel Rail Part Number: 17113547

Chevrolet Tahoe Fuel Rail Part Number: 89018109

Chevrolet Tahoe Fuel Rail Part Number: 12592182

Chevrolet Tahoe Fuel Rail Part Number: 12592183

Chevrolet Tahoe Fuel Rail Part Number: 12592186

Chevrolet Tahoe Fuel Rail Part Number: 12592187

Chevrolet Tahoe Fuel Rail Part Number: 17113651

Chevrolet Tahoe Fuel Rail Part Number: 89018111

Chevrolet Tahoe Fuel Rail Part Number: 97303658

| Page 1 of 2 |Next >

1-20 of 25 Results

Chevrolet Tahoe Fuel Rail

Want to cut long-term maintenance and repair costs? Choose OEM Fuel Rail. Those parts deliver top durability you can trust. On our site, you'll find a huge catalog of genuine Chevrolet Tahoe parts. Prices are unbeatable, so you can keep more in your pocket. Every OEM Chevrolet Tahoe Fuel Rail includes a manufacturer's warranty. You can also get an easy return policy that keeps buying risk free. Fast delivery, get your car on the road quickly. It's simple to search, compare, and order. Stop guessing about quality or fit. Order today and save with parts that last.

Chevrolet Tahoe Fuel Rail Parts and Q&A

- Q: How to replace the Fuel Injection Fuel Rail Assembly on Chevrolet Tahoe?A:The air cleaner outlet duct must be removed first before starting the fuel injection Fuel Rail assembly replacement. The correct technique should be used to release pressure from the fuel system. Proceed by unscrewing the engine wiring harness bracket nut followed by disconnecting the engine wiring harness electrical connectors to separate the evap purge solenoid along with MAP Sensor and ignition coil main electrical connector and Fuel Injectors while taking proper marks for reassembly. The ignition coil bracket stud requires removal of its engine wiring harness clip before moving the heater hose bracket by removing its retaining nut. The chassis fuel feed pipe quick connect fitting as well as the evap tube quick connect fittings at both the Intake Manifold and evap canister purge solenoid need removal. After disconnecting the evap canister purge solenoid retainer from the Fuel Rail you should remove the Fuel Rail bolts and carefully lift the assembly to prevent damage to injector electrical terminals and spray tips. Clean the Fuel Rail as needed while you remove both Fuel Injector retainers and fuel injectors which require replacing the o-ring seals at the top and bottom positions (2 and 4). Apply engine oil to new Fuel Injector o-ring seals before mounting them on the injectors before inserting the fuel injectors into the Fuel Rail with retainer installation. Install the Fuel Rail on the Intake Manifold until it rests in its proper position and tighten the Fuel Rail bolts to 10 nm before removing installation. Reconnect the evap tube and purge solenoid and the evap canister purge solenoid at its chassis tube quick connect fitting along with the Intake Manifold quick connect fitting. The technician reconnects the Fuel Rail quick connect fitting from the chassis fuel feed pipe while installing the pcv hose before gathering engine wiring harness branches over the engine. Follow these steps to install the engine wiring harness clip bolt by tightening it to 9 nm and position the heater hose bracket before tightening its nut to 9 nm. The engine wiring harness requires proper connection of electrical connectors to the ignition coil main electrical connector and electronic throttle control and fuel injectors and the cpa retainers must lock into place. Complete the procedure with a connecting step that involves your negative Battery Cable and a leak check when turning ignition on then off followed by the duct-based reinstallation of the air cleaner outlet.