ChevyParts

My Garage

My Account

Cart

OEM GMC Jimmy Distributor

Ignition Distributor- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

1 Distributor found

GMC Jimmy Distributor Assembly Part Number: 12598210

GMC Jimmy Distributor

Want to cut long-term maintenance and repair costs? Choose OEM Distributor. Those parts deliver top durability you can trust. On our site, you'll find a huge catalog of genuine GMC Jimmy parts. Prices are unbeatable, so you can keep more in your pocket. Every OEM GMC Jimmy Distributor includes a manufacturer's warranty. You can also get an easy return policy that keeps buying risk free. Fast delivery, get your car on the road quickly. It's simple to search, compare, and order. Stop guessing about quality or fit. Order today and save with parts that last.

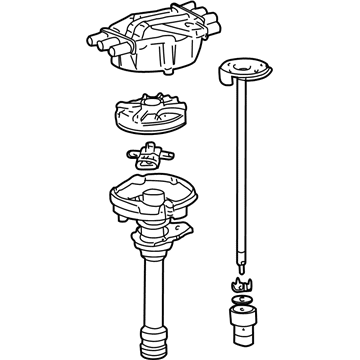

The Distributor of GMC Jimmy vehicle controls the ignition of the fuel in the combusted cylinder for the engine through high-voltage current distribution of the ignition coil to the spark plugs in the right firing sequence. Earlier variants had the distributor mechanically controlling the spark timing through the breaker points and advance weights; however, later models incorporated the electronic triggering device for better performance. The distributor has a rotating arm, a shaft marvelled by the camshaft, and a number of advance mechanisms for adjusting the spark point with reference to the speed of the engine and the vacuum in it. In future, such newer trends as the usage of the coil pack or individual coils in the contemporary automobiles can be attributed to the fact as the technologies have developed hence enhanced the control over ignition and performance. Highlighting on the aspects of durability and efficiency, the Distributor of GMC Jimmy vehicles helps in providing proper ignition and functioning of the vehicle's engine on the highway.

GMC Jimmy Distributor Parts Questions & Experts Answers

- Q: How to service and repair the distributor on GMC Jimmy?A:To service and repair the Distributor, start by separating it cautiously making whereby marking the Distributor driven gear, Distributor shaft, and rotor holes to observe their correct reassembly. Match the white paint sign on the lower stem of the Distributor to the pre-drilled indent hole on the bottom part of the gear. In case the rotor segment is not placed properly in v6 engine, then one will need to replace the Distributor. Pull the rotor after taking out the two screws from the rotor, pointing out the locating holes for rotor screw and locator pin. Complement the square-cut hole of the vane wheel with the camshaft position gp cmosition (CMP) sensor, next remove the two screws operating the cmp sensor and dispose it. Also, do not miss the small groove (dimple) below the roll pin hole on one side of the gear when disassembling for proper orientation in reassembly. Mount both ends of the support Distributor drive gear in v-block or equivalent fixtures, then use a suitable punch and drive out the roll pin for removal of the driven gear from the Distributor shaft followed by the round washer, tang washer and shim washer and the old oil seal. For assembly, align the square-cut hole of the vane wheel for the cmp sensor and introduce the sensor into the housing. Install two new screws of the cmp sensor which are to be tightened to 2.2 n.m (20 lb in). Determine the proper rotor mounting position at rotor screw holes and locator pin holes and assist the Distributor rotor according to the index marks and closing with two hold down screws at 1.9nm (17lb in). Mount the shim washer at the bottom of the shaft of the Distributor, then the tang washer and round washer. Mount the driven gear utilising the index marks so that the rotor segment is oriented as shown (for a V6 or V8 engine) and have the white paint mark at the bottom stem of the Distributor be in line with the pre-drilled indent hole at the bottom of the gear. If the driven gear is not installed correctly, the dimple will be about 180 degrees away from the rotor segment. Support the Distributor drive gear in a v-block or similar fixture, and then insert the roll pin with an appropriate punch and hammer to attach the driven gear. Finally, install a new oil seal under mounting flange of the Distributor base and install the Distributor.