ChevyParts

My Garage

My Account

Cart

OEM GMC Sierra 3500 Exhaust Pipe

Exhaust Tail Pipe- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

59 Exhaust Pipes found

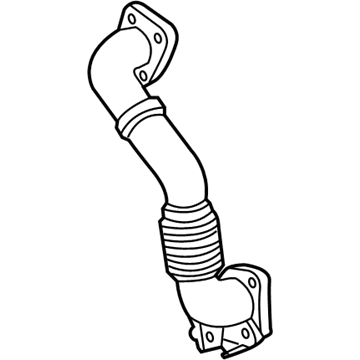

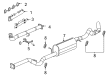

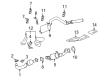

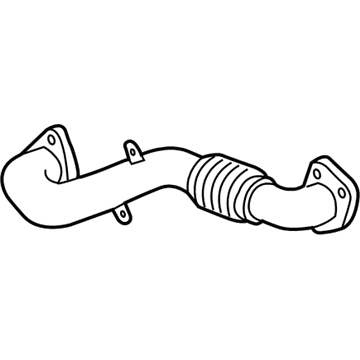

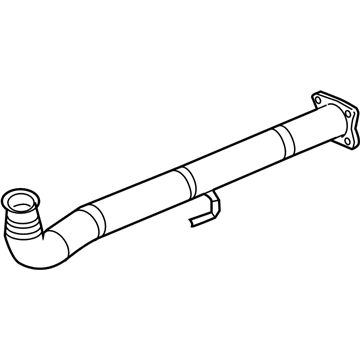

GMC Sierra 3500 Inlet Pipe Part Number: 97223166

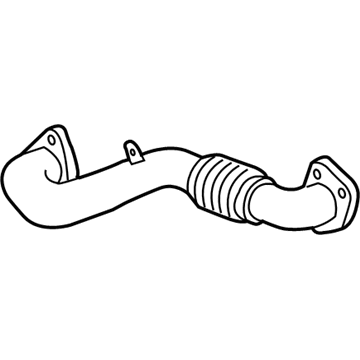

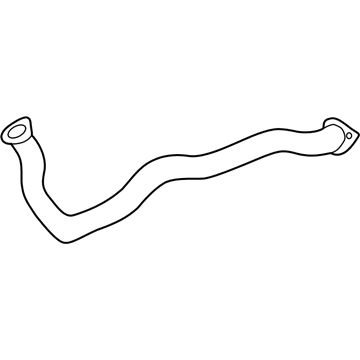

$200.70 MSRP: $300.06You Save: $99.36 (34%)Ships in 1-3 Business DaysGMC Sierra 3500 Exhaust Pipe Part Number: 97246408

$218.31 MSRP: $326.38You Save: $108.07 (34%)Ships in 1-3 Business DaysGMC Sierra 3500 Inlet Pipe Part Number: 97223167

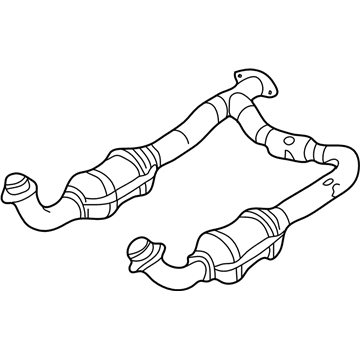

$165.76 MSRP: $237.18You Save: $71.42 (31%)Ships in 1-3 Business DaysGMC Sierra 3500 Catalytic Converter Part Number: 19420109

$933.52 MSRP: $1389.07You Save: $455.55 (33%)Ships in 1-3 Business DaysGMC Sierra 3500 Catalytic Converter Part Number: 19420124

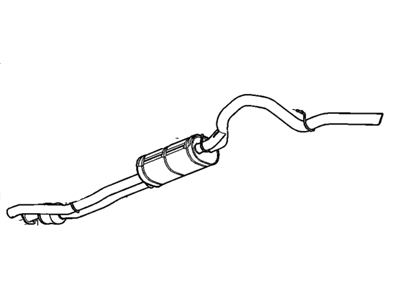

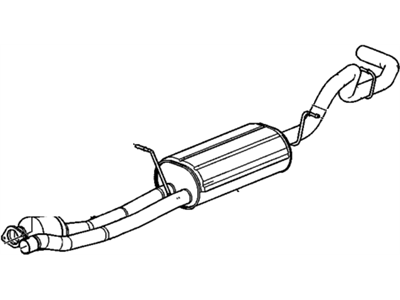

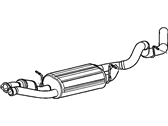

$970.06 MSRP: $1443.93You Save: $473.87 (33%)GMC Sierra 3500 Muffler Part Number: 15798957

$942.56 MSRP: $1402.65You Save: $460.09 (33%)Ships in 1-3 Business DaysGMC Sierra 3500 Muffler Part Number: 15798961

$1071.28 MSRP: $1595.91You Save: $524.63 (33%)Ships in 1-3 Business Days

GMC Sierra 3500 Inlet Pipe Part Number: 97365041

$200.92 MSRP: $300.39You Save: $99.47 (34%)

GMC Sierra 3500 Inlet Pipe Part Number: 97303648

GMC Sierra 3500 Inlet Pipe Part Number: 97302261

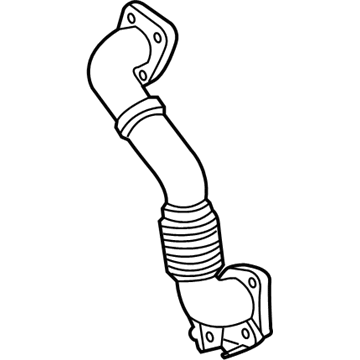

GMC Sierra 3500 Exhaust Pipe Part Number: 97223168

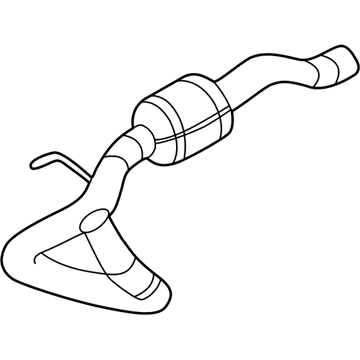

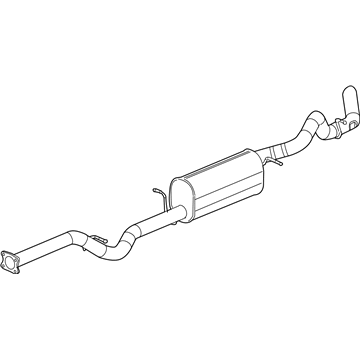

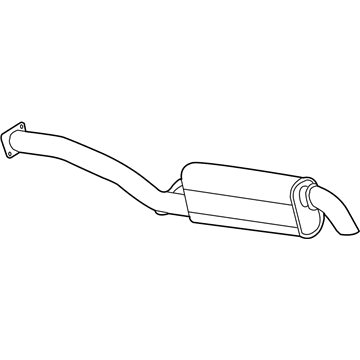

$144.95 MSRP: $216.71You Save: $71.76 (34%)GMC Sierra 3500 Muffler & Pipe Part Number: 15262865

$746.18 MSRP: $1120.61You Save: $374.43 (34%)GMC Sierra 3500 Muffler Part Number: 15798946

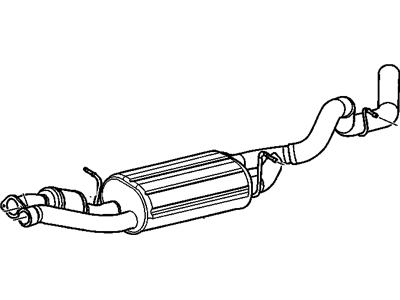

$1007.38 MSRP: $1500.27You Save: $492.89 (33%)GMC Sierra 3500 Muffler & Pipe Part Number: 15229357

GMC Sierra 3500 Muffler & Pipe Part Number: 15262863

GMC Sierra 3500 Muffler Part Number: 88983229

GMC Sierra 3500 Muffler Part Number: 88983234

GMC Sierra 3500 Inlet Pipe Part Number: 97354615

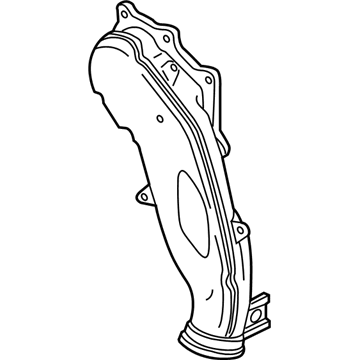

GMC Sierra 3500 Front Pipe Part Number: 15068671

| Page 1 of 3 |Next >

1-20 of 59 Results

GMC Sierra 3500 Exhaust Pipe

Want to cut long-term maintenance and repair costs? Choose OEM Exhaust Pipe. Those parts deliver top durability you can trust. On our site, you'll find a huge catalog of genuine GMC Sierra 3500 parts. Prices are unbeatable, so you can keep more in your pocket. Every OEM GMC Sierra 3500 Exhaust Pipe includes a manufacturer's warranty. You can also get an easy return policy that keeps buying risk free. Fast delivery, get your car on the road quickly. It's simple to search, compare, and order. Stop guessing about quality or fit. Order today and save with parts that last.

GMC Sierra 3500 Exhaust Pipe Parts and Q&A

- Q: How to replace the Exhaust Pipe on 6.0L, 6.6L, and 8.1L engines on GMC Sierra 3500?A:The exhaust manifold pipe replacement on 6.0l, 6.6l and 8.1l engines requires vehicle elevation with proper support alongside the installation of a suitable transmission jack. First drain the transmission mount to transmission support nuts before raising the transmission off the support. Then extract the transmission support crossmember bolts as well as the crossmember itself. First disconnect the Oxygen Sensor of 6.0l or 8.1l engines through clip removal around the engine harness and cpa retainer and electrical connector removal before taking out the Oxygen Sensor. The transmission requires lowering next while you remove exhaust manifold pipe nuts. If you are working on a 6.6l engine then remove exhaust Muffler nuts and slide up the Exhaust Pipe clamp onto the Exhaust Pipe adapter. Clear the exhaust manifold pipe from its position and throw the seal into waste disposal. The installation process for the exhaust manifold pipe starts with applying water-based lubrication to the hanger bracket and inserting the hanger through the bracket when working with a vehicle powered by 6.6l. The installation of a new exhaust manifold pipe seal for 6.0l engines with y91 rpo must be completed before fitting the exhaust manifold pipe. The installation of hanger bracket for 6.0l or 8.1l engines requires sliding the hanger into bracket twice while using new placement seals. Use 40 nm torque for the Exhaust Pipe clamp while applying the same torque value to the Muffler nuts. Tighten 6.0l and 8.1l exhaust manifold pipe nuts to 50 nm. Apply anti-seize compound gm p/n 12377953 to the Oxygen Sensor threads after replacing the exhaust manifold pipe and perform a 42 nm (31 ft. Lbs.) torque on it. The replacement of the Oxygen Sensor electrical connector along with the cpa retainer and clip should be completed if the Exhaust Pipe was left undisturbed. The exhaust Muffler installation for 6.0l or 8.1l engines should be followed by transmission support crossmember bolt installation which requires 95 nm (70 ft. Lbs.) torque setting. Start by lowering the transmission onto the support then install transmission mount support nuts before tightening them to 40 nm (30 ft. Lbs.). Afterward remove support from transmission and complete the lowering process of the vehicle.